Temporary supporting device of driving machine

A technology of temporary support and roadheader, which is applied to mine roof supports, mining equipment, earthwork drilling, etc., can solve the problems of obvious roof damage, inability to move the continuous support roof, frequent lifting of temporary support devices, etc. The effect of improving the driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

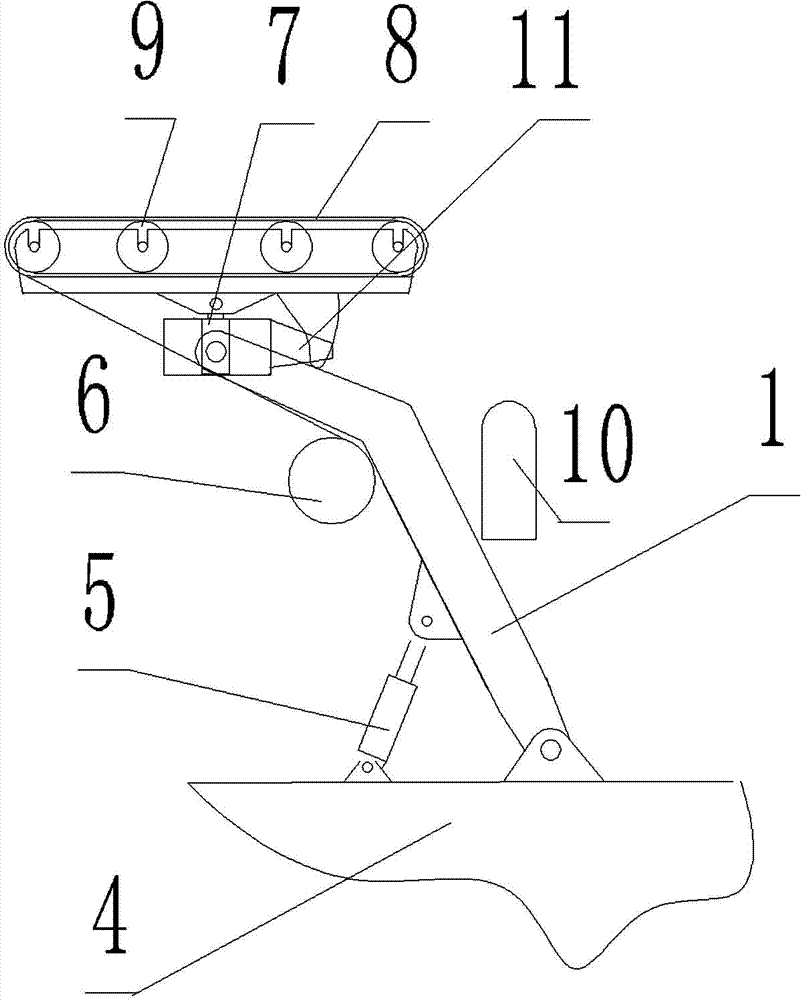

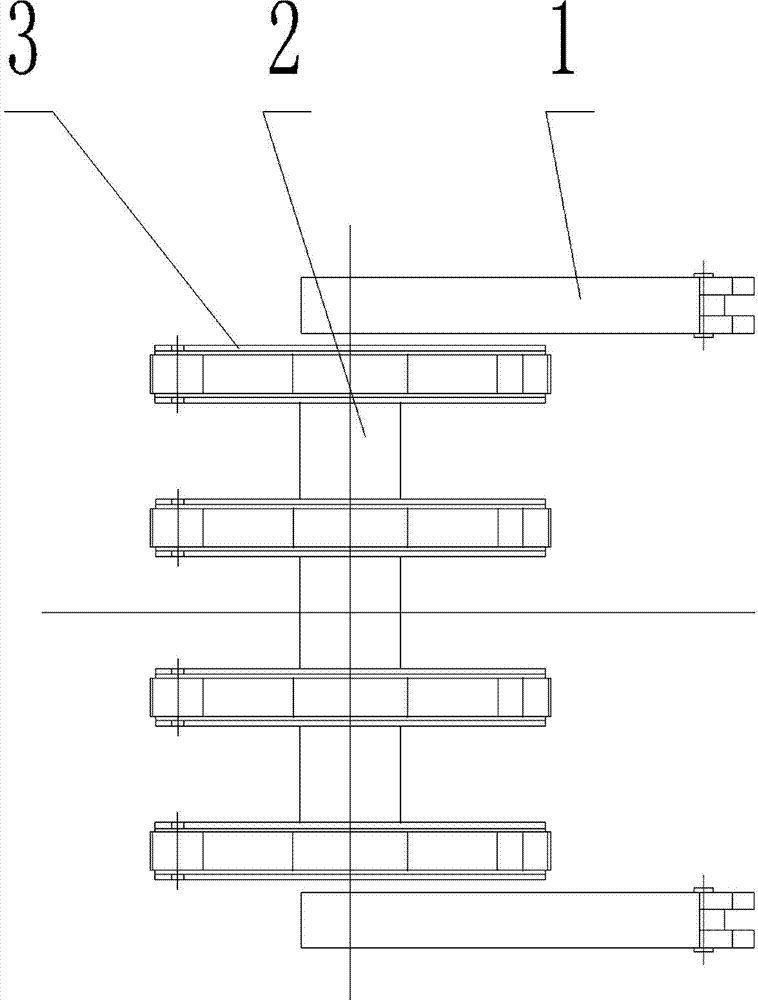

[0013] The temporary support device is installed on the roadheader body 4, and its structure is as follows: figure 1 , figure 2 As shown, it is composed of boom 1, lifting jack 5, crossbeam 3, longitudinal beam 2, longitudinal beam jack 7, roller 9, crawler belt 8, accumulator 10, top net storage 6, anti-deflection guide plate 11. The lower part of the boom 1 is hinged with the roadheader body 4 , and the upper part is hinged with the beam 3 , and the lifting jack 5 is installed between the angle formed between the boom 1 and the roadheader body 4 . A plurality of longitudinal beams 2 are installed on the beam 3, and several rollers 9 are installed on the longitudinal beam 2, crawler belts 8 are installed on the rollers 9, and an anti-deflection guide plate 11 is installed between the longitudinal beam 2 and the beam 3. The beam jack 7 is connected between the beam 3 and the longitudinal beam 2 . Due to the anti-deflection effect of the anti-deflection guide plate 11 betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com