Tunneling and anchoring machine capable of achieving one-time tunneling and tunneling and anchoring parallel operation

A technology of parallel operation of bolt digging and bolt digging machine, which is applied in the direction of cutting machinery, slitting machinery, bolt installation, etc., and can solve the problems of increasing equipment conversion, slow bolt speed, and inability to carry out high-efficiency operation of anchor tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

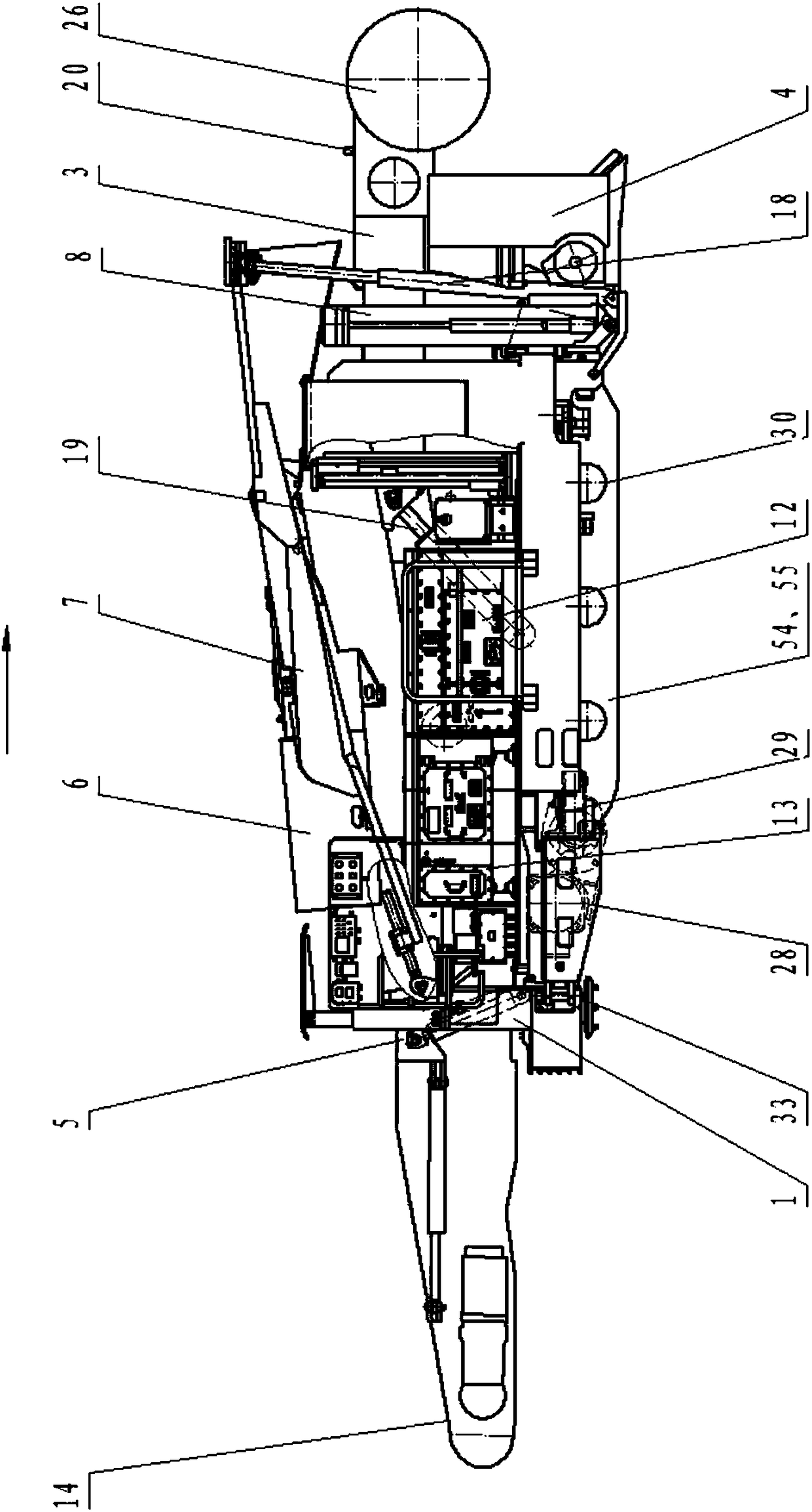

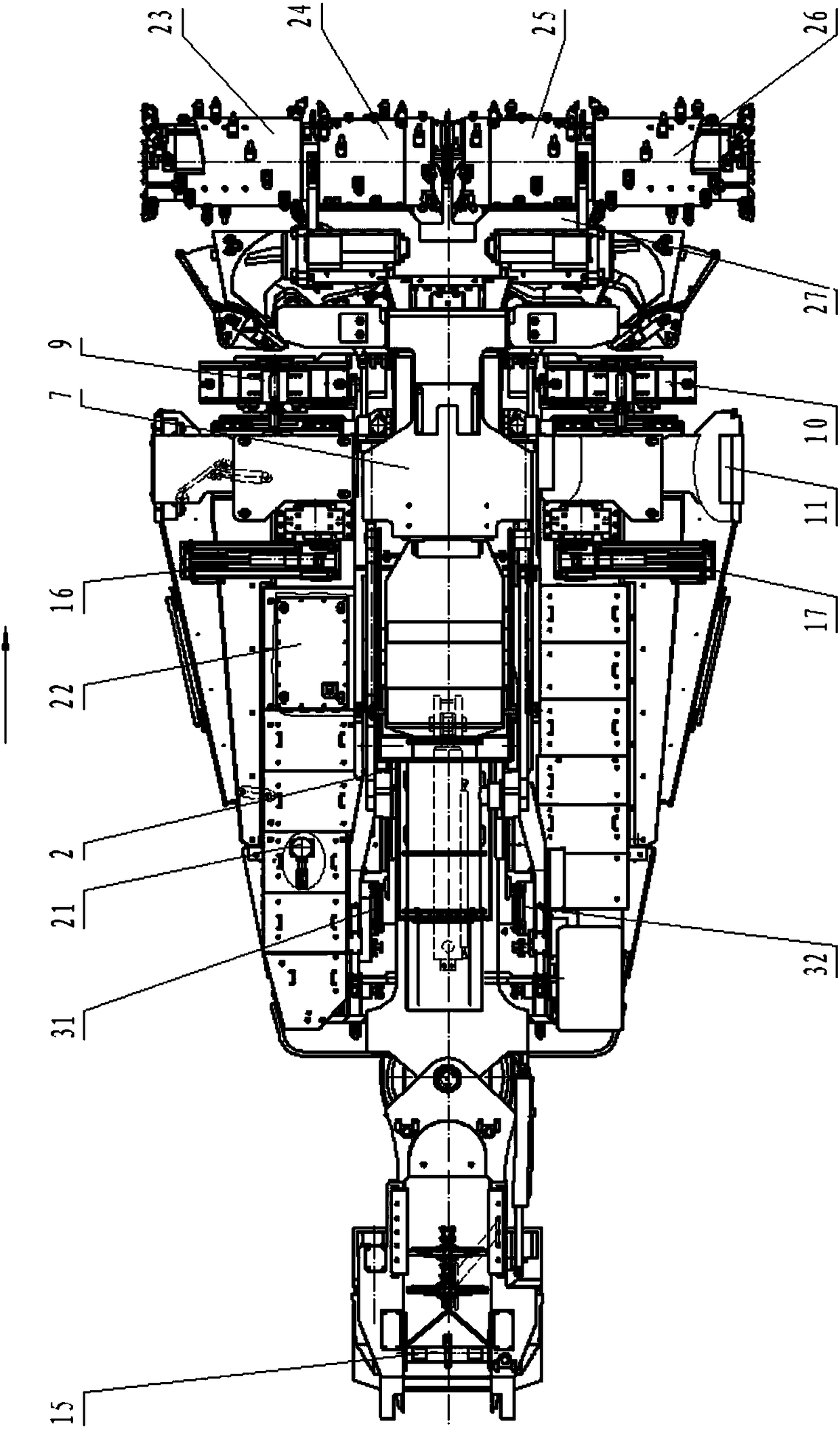

[0023] figure 1 , 2 Shown is the overall structure diagram of the bolter miner. The position and connection relationship of each part must be correct and the installation should be firm.

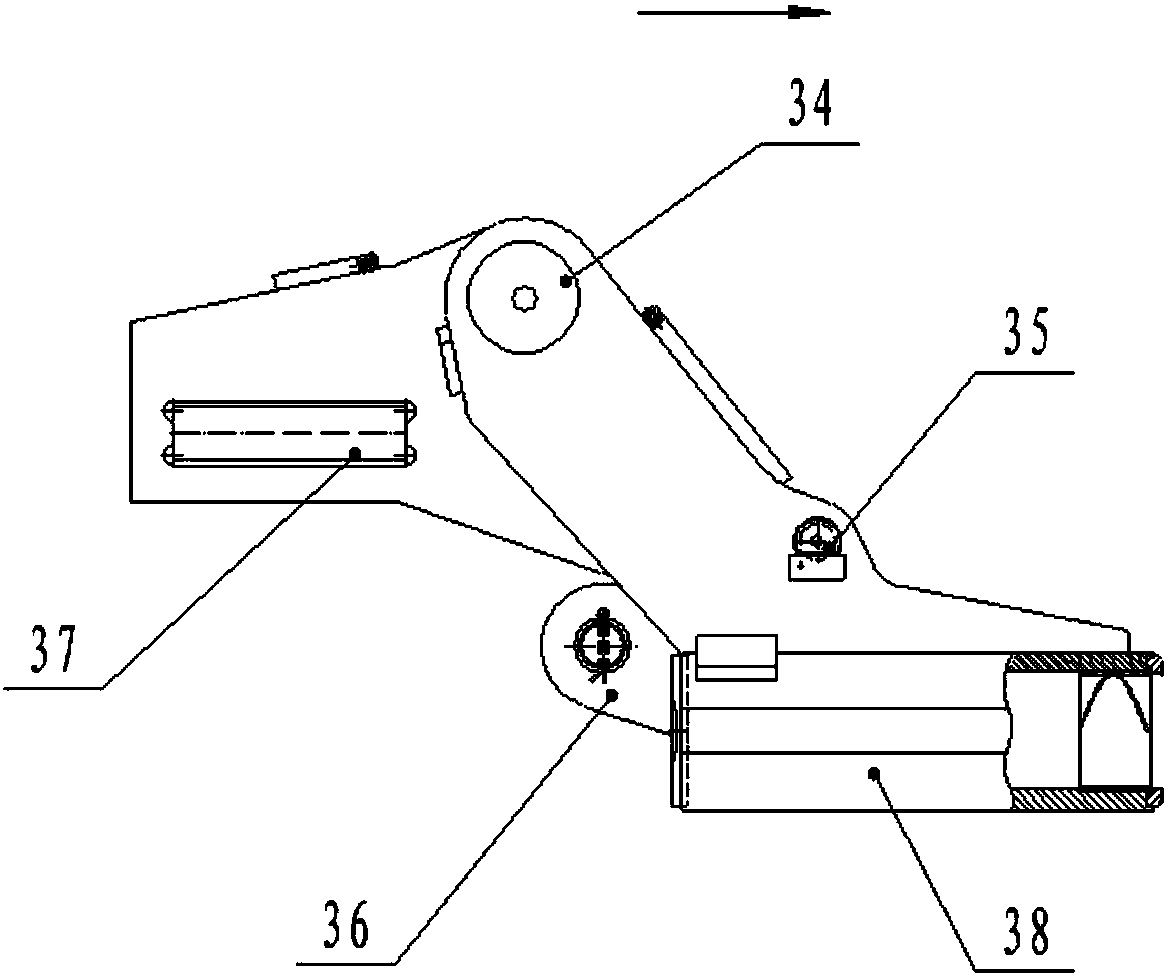

[0024] The bolter is a rectangular body as a whole, the upper part of the bolter is the main frame 1, and the left crawler running mechanism 54 and the right crawler running mechanism 55 are arranged on the left and right sides of the lower part of the main frame 1; Mechanism 6, temporary support mechanism 7, anchor drilling mechanism 8, cutting mechanism 3, temporary support oil cylinder 18, main oil tank 30, auxiliary oil tank 22, main electric control box 12, frequency conversion electric control box 13, cutting lifting oil cylinder 19, Guide tension mechanism 29, travel reducer 28, sub-frame 2, first travel motor 31, second travel motor 32, centralized lubrication mechanism 21, left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com