Novel counter-rotating fan

A ventilator, rotary technology, applied in the field of new counter-rotary ventilators, can solve the problems of restricting development, weakening the ability of rotary technology to do work on airflow, etc., to reduce input costs, reduce structural complexity, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

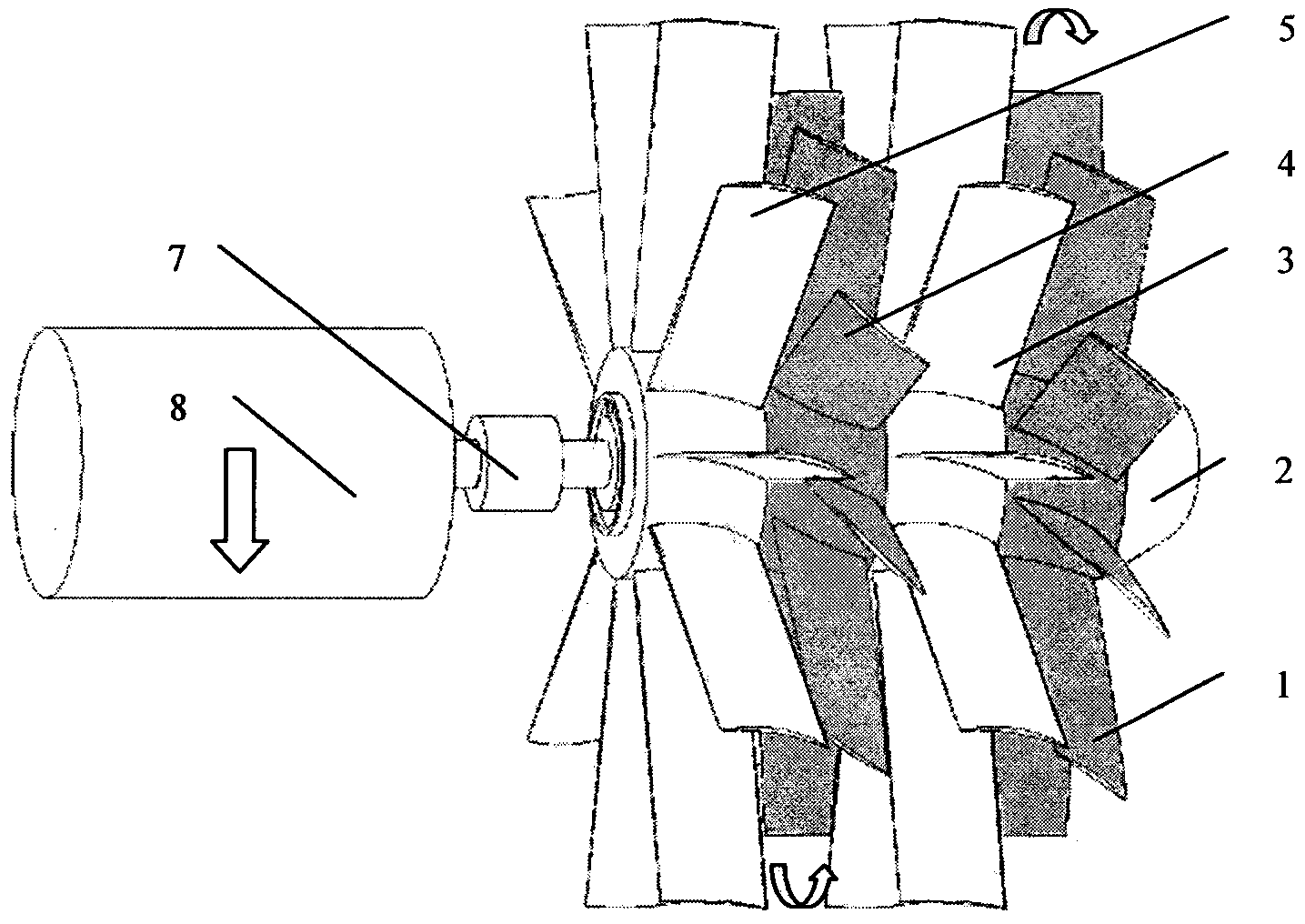

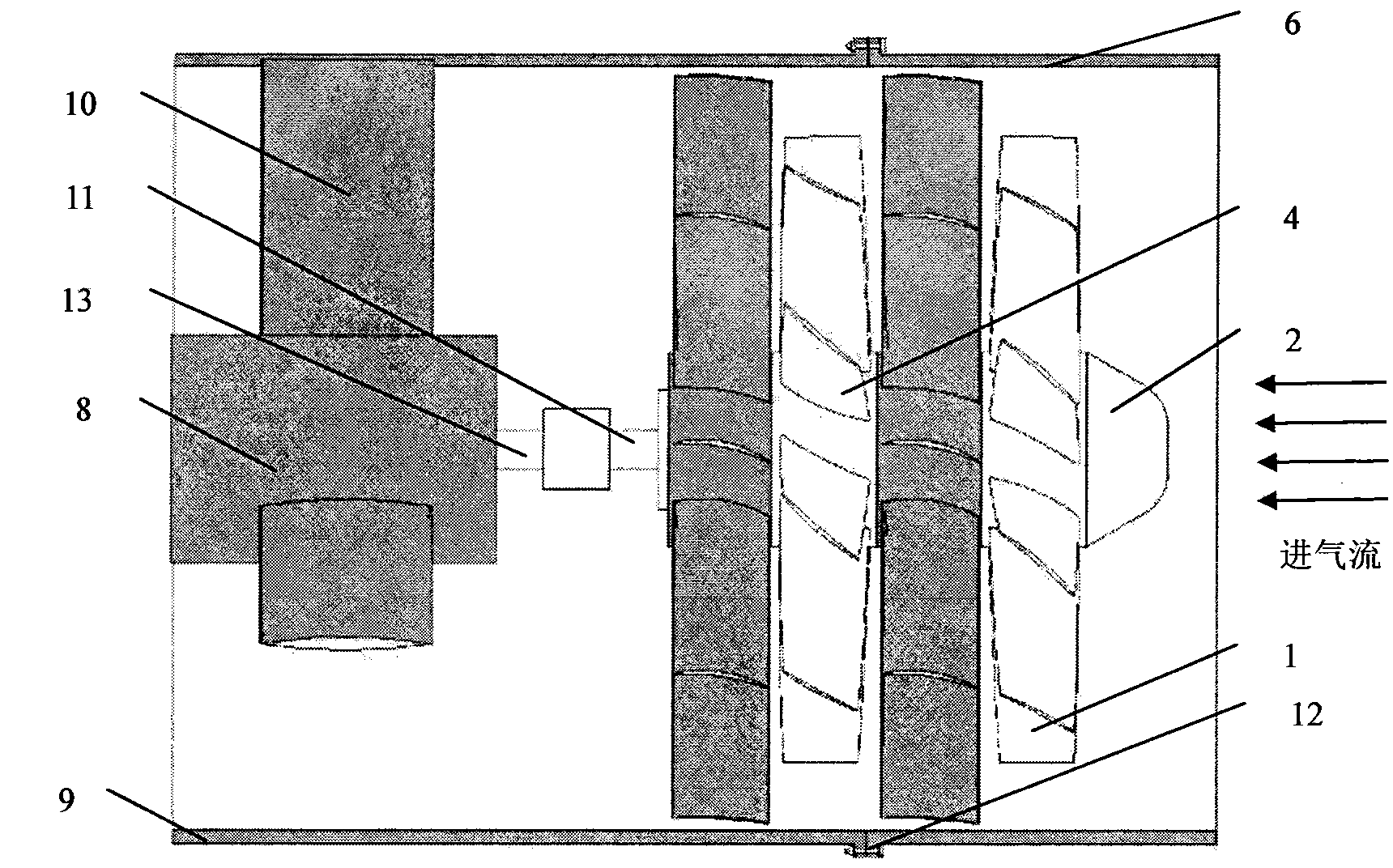

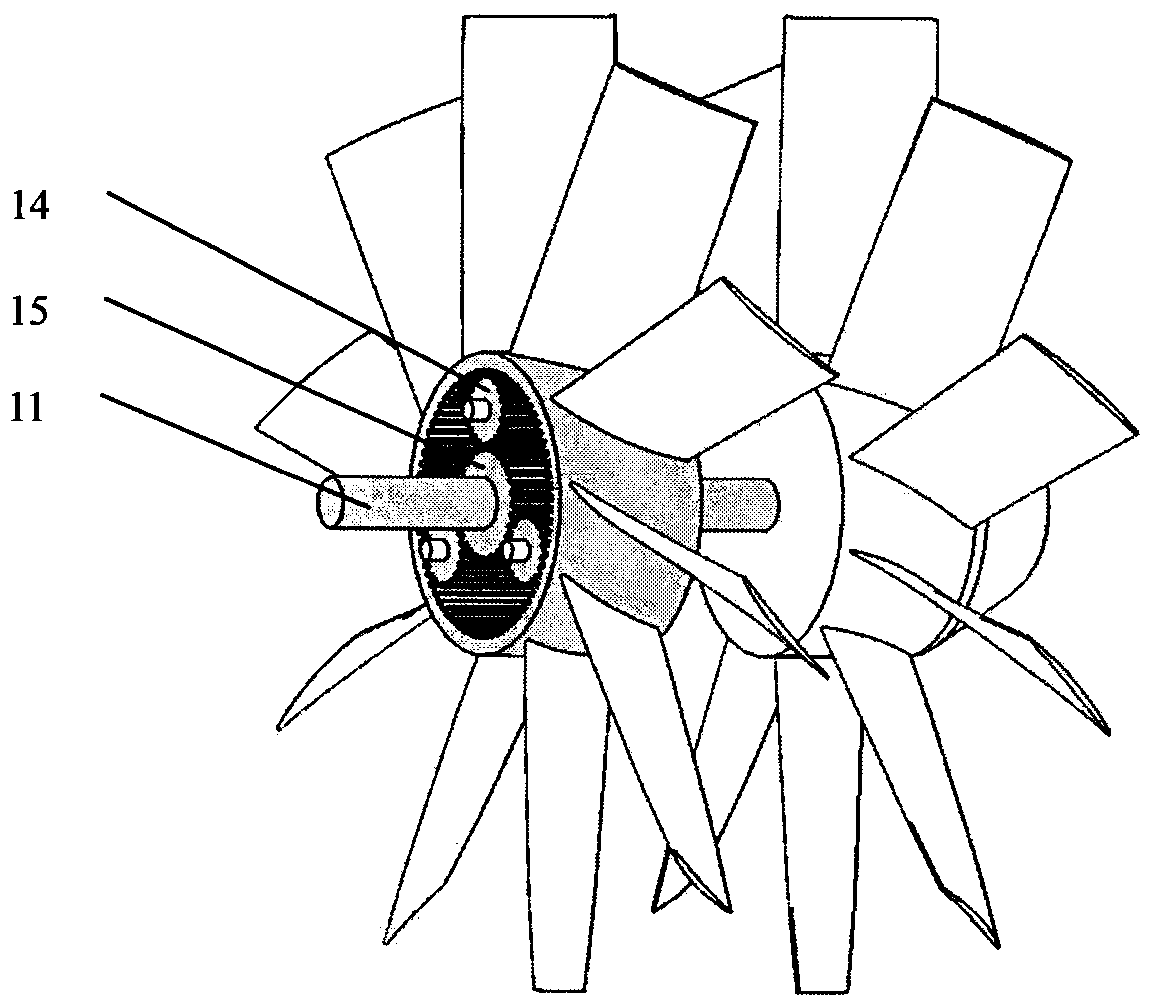

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] The new counter-rotating fan is mainly used in mines, large factories, tunnels, cooling towers, ships and buildings where ventilation, dust removal and cooling are required, especially where high-pressure airflow is required.

[0032] For the new counter-rotating fan, according to the design drawings, the manufacturer of this kind of counter-rotating fan will install it according to the following steps after producing all the parts:

[0033] 1. As attached Figure 5 As shown, the double-row tapered roller bearing 26 is installed on the core rotating shaft A section 11, and the right end surface of the double-row tapered roller bearing 26 is in contact with the shoulder of the core rotating shaft A section 11. Insert the sleeve B27 into the shaft from the left end of section A of the core rotating shaft, make the sleeve B27 contact with the left end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com