Centrifugal pump impeller

A centrifugal pump impeller and impeller disc technology, which is applied to pumps, pump components, non-variable pumps, etc., and can solve the problems of centrifugal pumps without blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

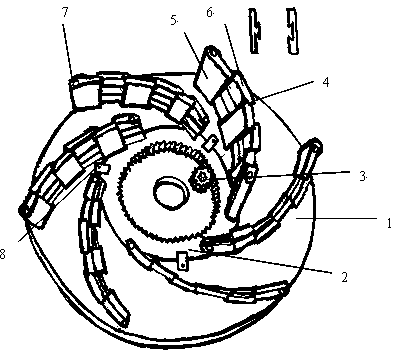

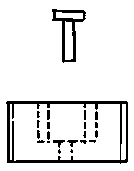

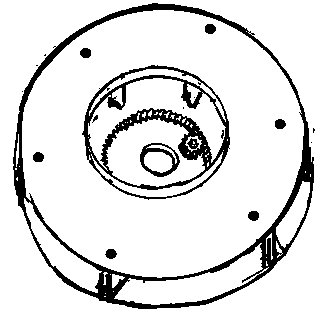

[0013] figure 1 It is one of the types of the structural principle diagram of the present invention. There is a circular groove in the middle of the impeller disc 1, and a ring 2 with teeth on the inner side is placed in the annular groove. The pinion gear 3 meshes, and there are 6 blades 4 on the top of the impeller disc 1, and the blades 4 are composed of several rectangular blocks 5 with convex grooves and rectangular blocks 6 with concave grooves connected in sequence. The cross-sectional view of the rectangular block 5 with the convex groove and the rectangular block 6 with the concave groove is shown in figure 1 Shown in the upper right of the above, the length of blade 4 can be elongated, shortened. There are two holes at both ends of each blade 4, and the screws 7 pass through the two holes on the blade to install the blades in the screw holes on the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com