Graphene paste and conductive ink and preparation methods of graphene paste and conductive ink

A conductive ink and graphene technology, applied in inks, household appliances, applications, etc., can solve the problems that the electrical properties need to be improved, and the structural defects of graphene oxide cannot be completely repaired, so as to achieve adjustable performance, simple and gentle process, and method The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present embodiment also provides the preparation method of above-mentioned graphene slurry, and described preparation method comprises the steps:

[0058] (1) obtain the electrolytic solution that contains sulfuric acid and sulfate;

[0059] (2) In the electrolyte, graphite is used as a positive electrode, and an operating voltage is applied to peel off the graphite to obtain a suspension;

[0060] (3) Remove the liquid part in the suspension, wash and sonicate the obtained solid part, and then place it at -100°C ~ -60°C for 2h ~ 8h, and then place it at -56°C ~ - 35h~55h at 44°C to obtain graphene;

[0061] (4) Mix the graphene, dibasic acid ester, and ethanol, and remove the ethanol after homogeneous treatment to obtain graphene slurry.

[0062] In one embodiment, the homogenization treatment conditions include: a speed of 3000 rpm to 10000 rpm, and a time of 30 min to 80 min.

[0063] In one embodiment, the method of removing the ethanol includes but not limit...

Embodiment 1

[0075] (1) Preparation of graphene slurry

[0076] 1) Configure 100mL of a mixed electrolyte of sulfuric acid and ammonium sulfate with a molar ratio of 1:1 (the solvent is deionized water), with a total concentration of 0.1mol / L, and put it into a 120mL electrolytic cell.

[0077] 2) 2cm×5cm graphite foil and 2cm×2cm platinum sheet were used as positive and negative electrodes respectively, and a working voltage of 10V was applied to gradually peel off the graphite foil.

[0078] 3) Pour the suspended liquid after stripping into a suction filter, and wash three times successively with 300 mL deionized water and 300 mL ethanol.

[0079] 4) Then transfer to a beaker and add 200mL deionized water, ultrasonically crush for 10min, place in -80°C refrigerator for 6h, and then put it into a freeze dryer at -50°C for 48h to obtain 8% oxygen content Graphene powder.

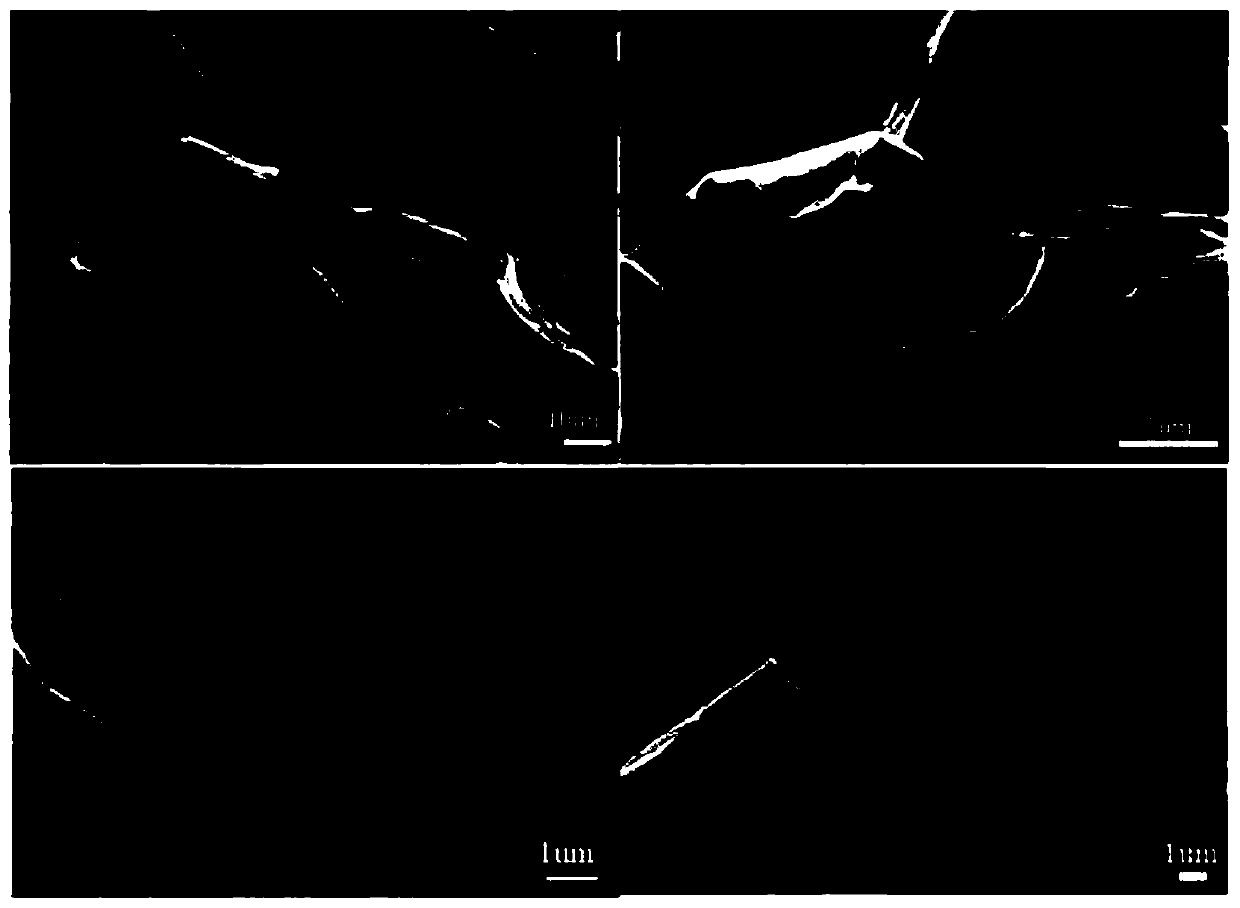

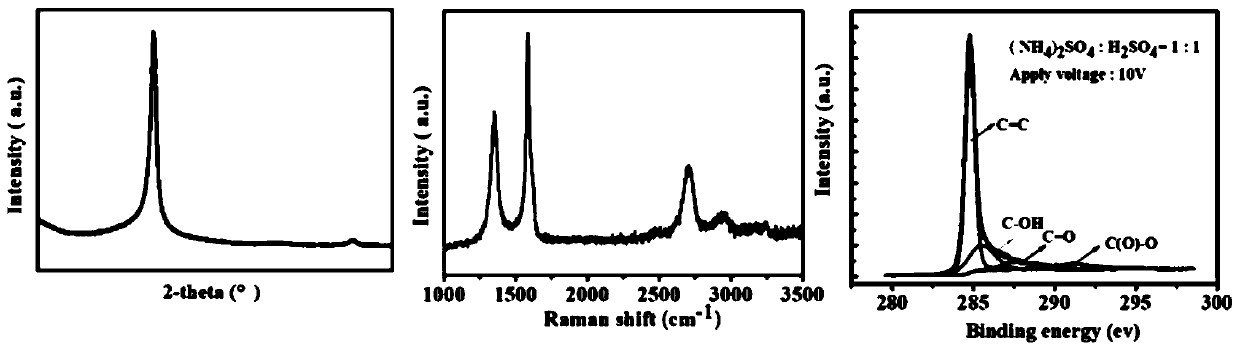

[0080] The scanning electron micrograph of the graphene powder that this step prepares sees figure 1 , XRD, Raman, ...

Embodiment 2

[0090] (1) Preparation of graphene slurry

[0091] 1) Configure 100mL of mixed electrolyte of sulfuric acid and sodium sulfate with a molar ratio of 0.5 (the solvent is deionized water), the total concentration is 0.3mol / L, and put it into a 120mL electrolytic cell.

[0092] 2) 2cm×5cm graphite foil and 2cm×2cm platinum sheet were used as positive and negative electrodes respectively, and a working voltage of 10V was applied to gradually peel off the graphite foil.

[0093] 3) Pour the suspended liquid after stripping into a suction filter, and wash three times successively with 300 mL deionized water and 300 mL ethanol.

[0094] 4) Then transfer to a beaker and add 200mL of deionized water, ultrasonically crush for 10 minutes, place in a -100°C refrigerator for 2 hours, and then put it into a freeze dryer at -56°C for 35 hours.

[0095] 5) Mix 1.5g of the obtained graphene powder, 25mL of dibasic acid ester, and 80mL of ethanol, and disperse homogeneously at 8000rpm for 60mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com