Welding and cutting torch

A technology of welding and cutting, the main body, applied in the field of welding and cutting torches, can solve the problems of gap distance and design requirements error, welding and cutting torch work is not stable enough, welding and cutting torch processing and production are complicated, etc., to achieve accurate and stable adjustment, and avoid easy breakage , The effect of easy to adjust the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

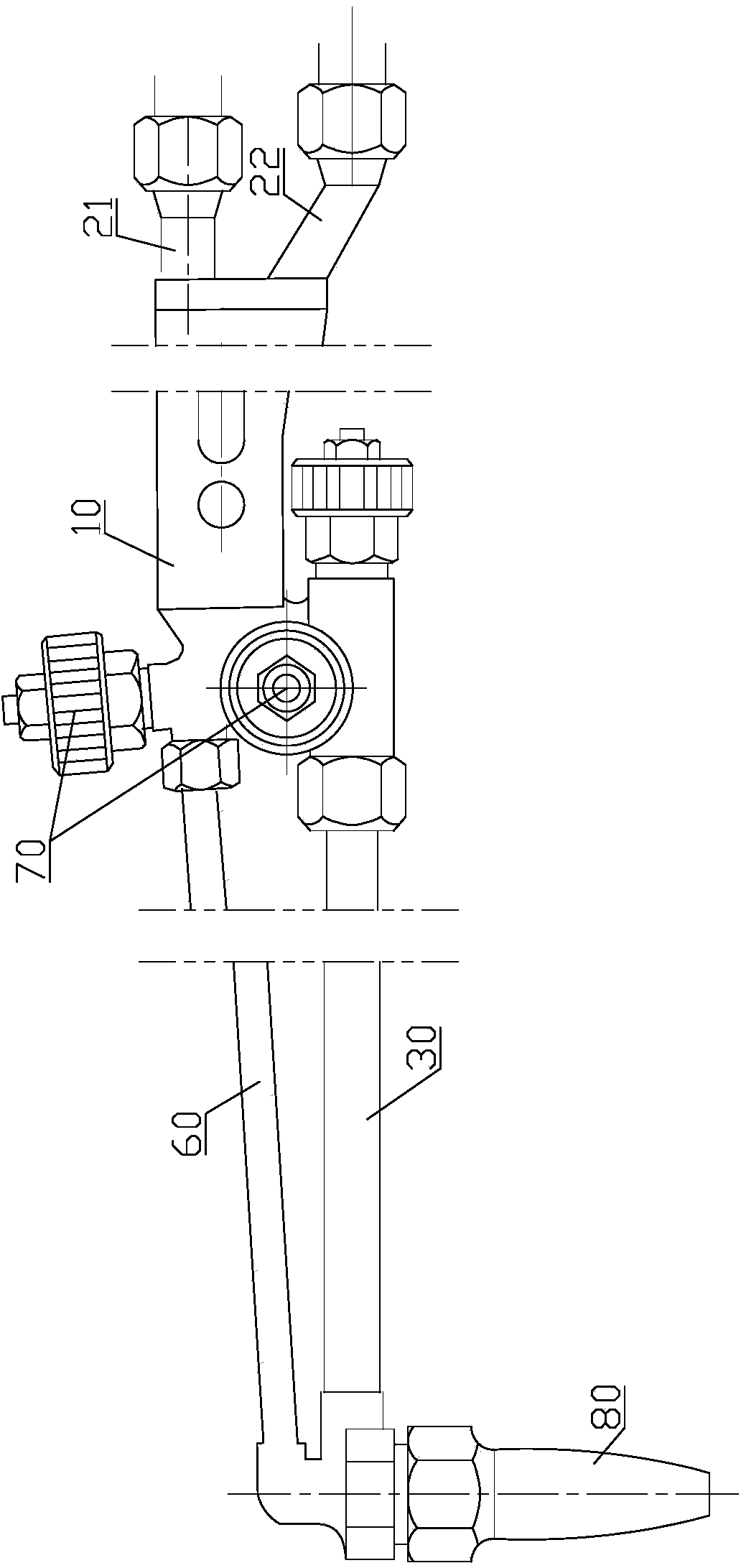

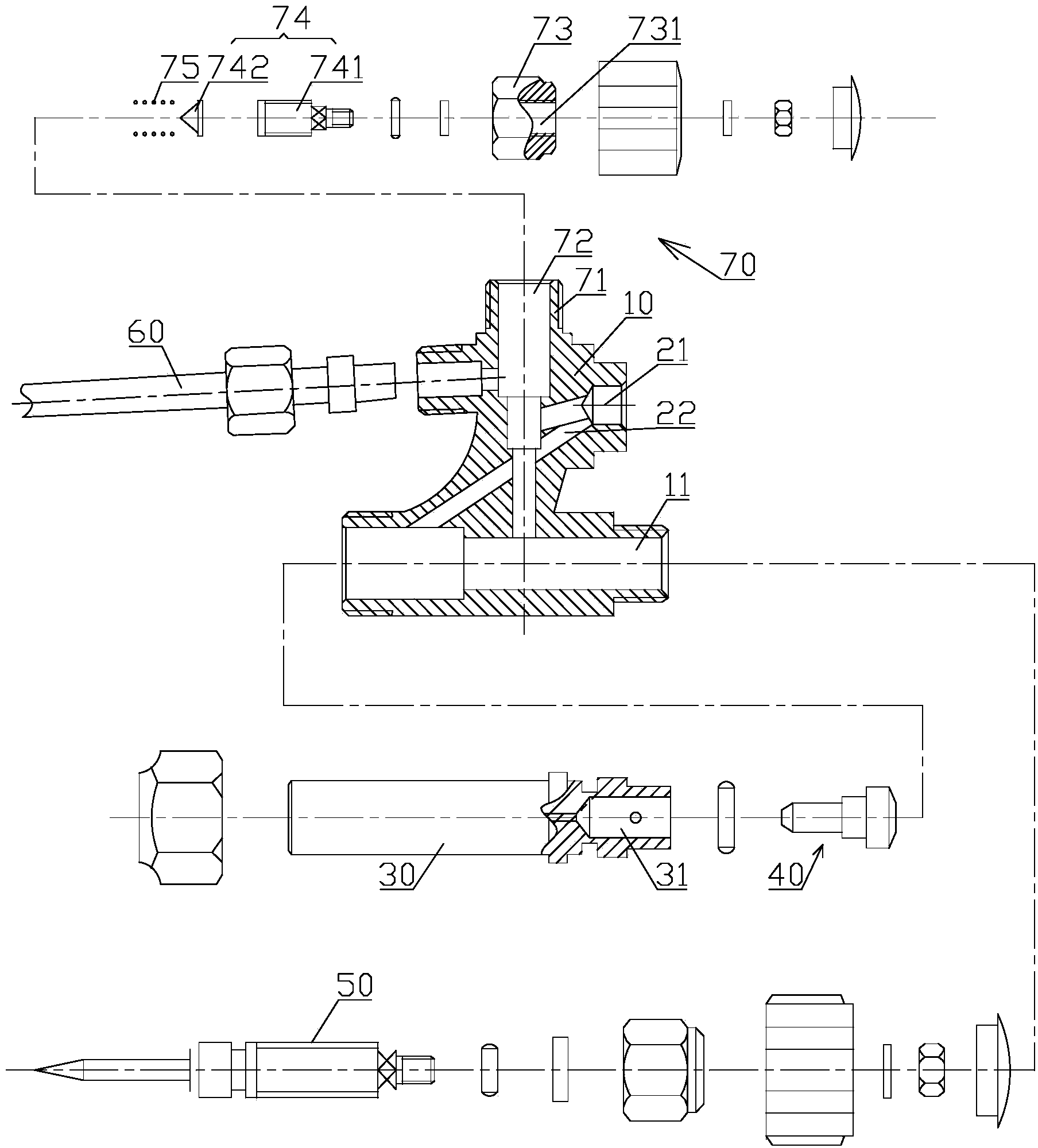

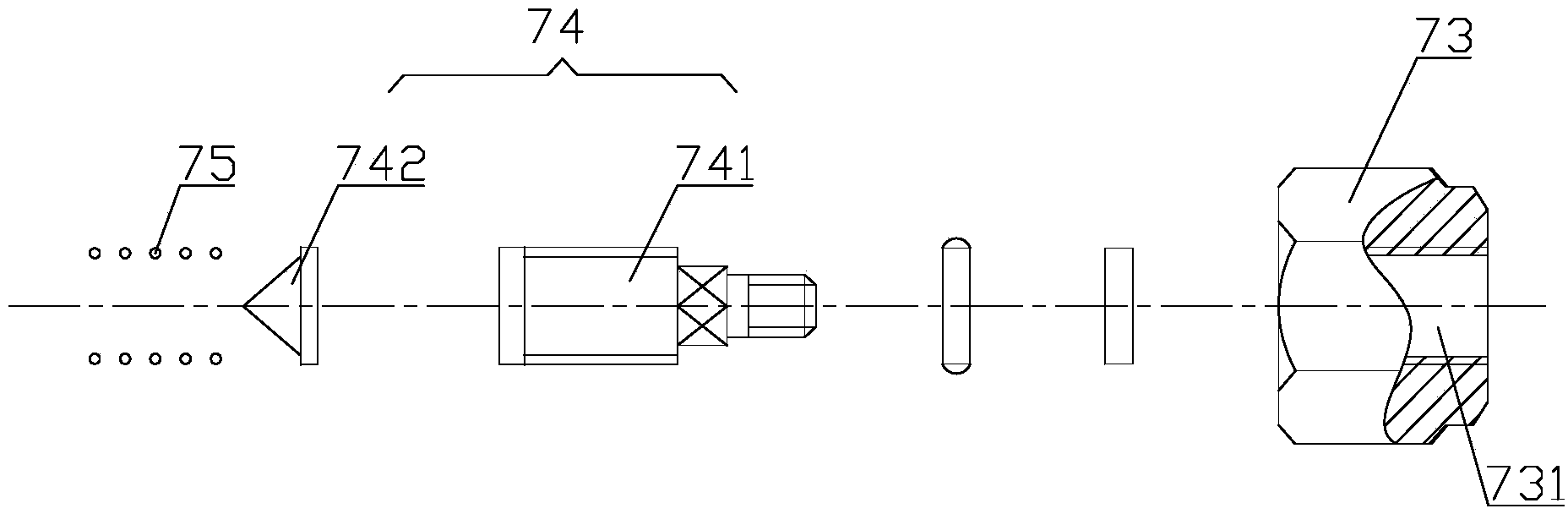

[0016] Examples, see figure 1 and figure 2 As shown, the welding and cutting torch includes a main body 10 . The lower part of the main body 10 is provided with a through hole 11 passing through front and back, and an air pipe 21 and a gas pipe 22 communicate with the inside of the through hole 11 . The front opening of the through hole 11 is screwed with a suction pipe 30 , the rear opening is provided with an adjustment needle 50 , and the through hole 11 is provided with a nozzle 40 between the injection pipe 30 and the adjustment needle 50 . The rear portion of the suction pipe 30 is provided with a cylindrical insertion hole 31 . The front portion of the nozzle 40 protrudes into the insertion hole 31 . Simultaneously, the front side upper part of this main body 10 is provided with the regulating pipe 60 that communicates with the side wall of this air pipe 21, and the front end of this regulating pipe 60 communicates with the front end of this suction pipe 30 and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com