Gray pig iron pipe mechanical cleaning and dust removing device

A technology of dust removal device and gray cast iron, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding frame, etc., can solve the problems of low grinding efficiency, poor grinding quality, environmental pollution, etc. The effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

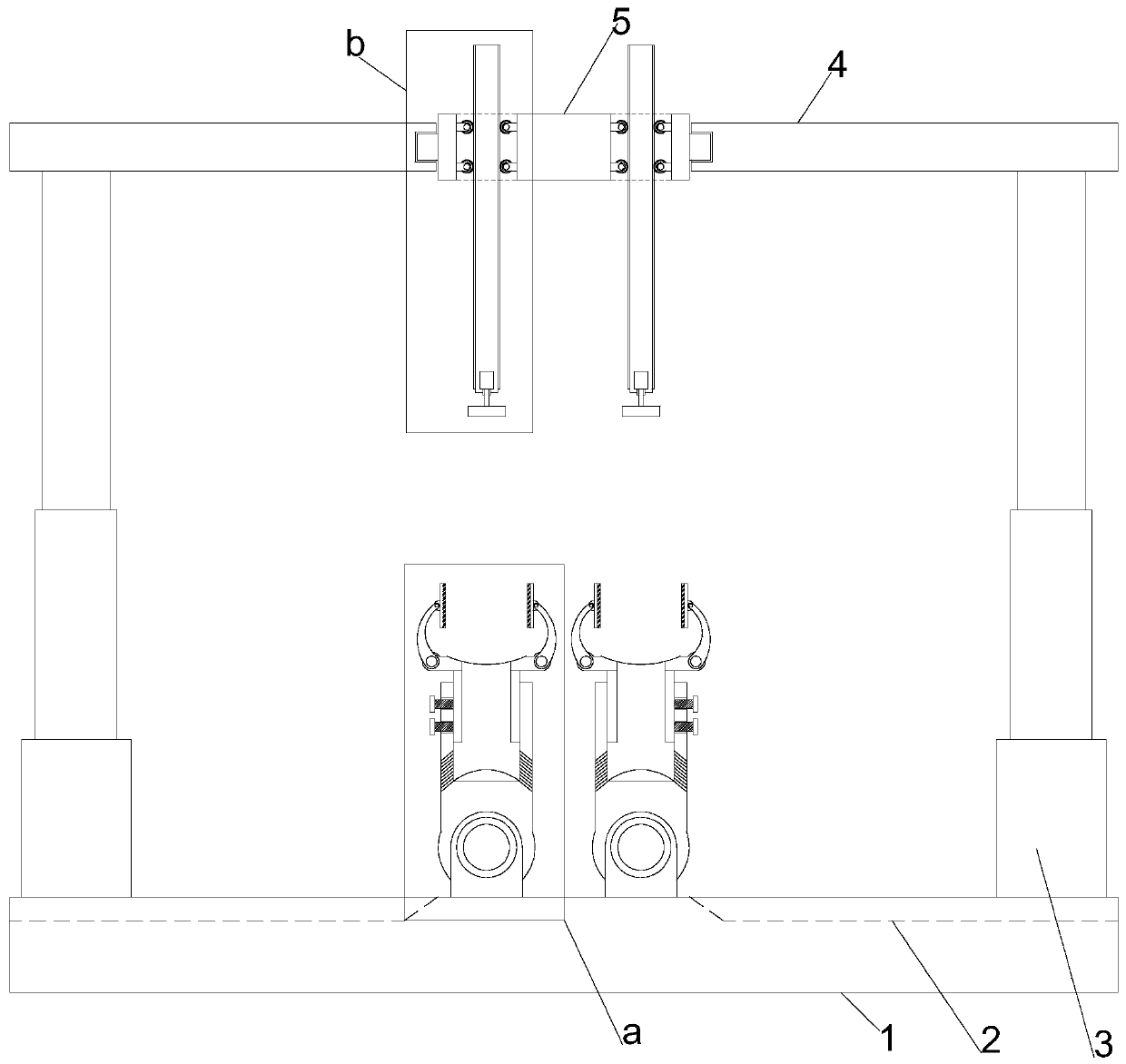

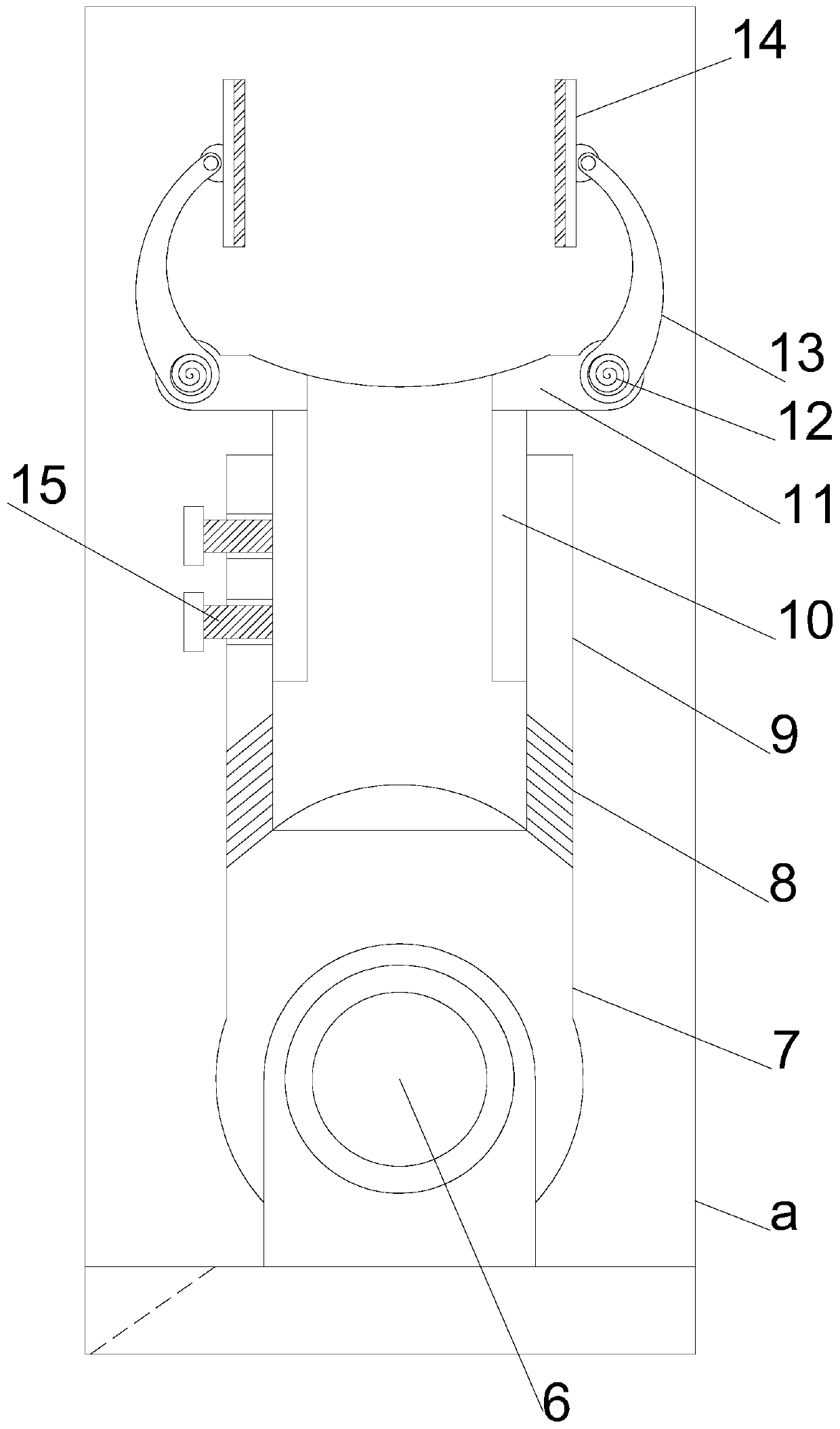

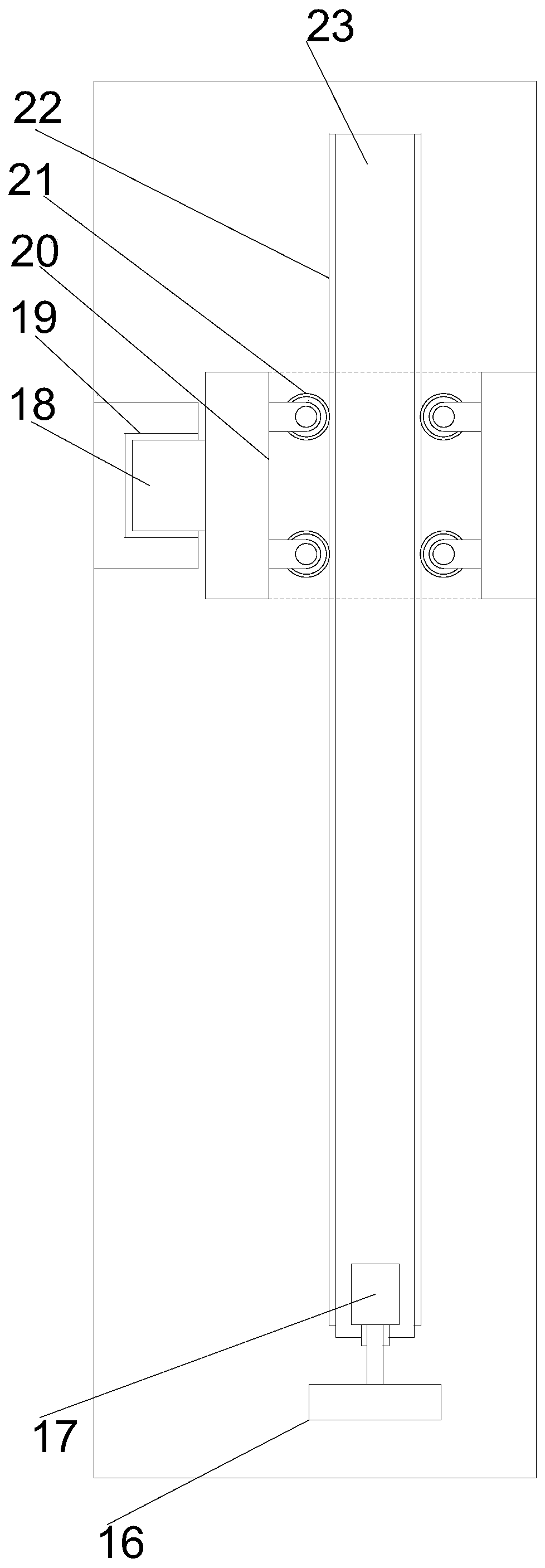

[0022] see Figure 1~4 , in an embodiment of the present invention, a gray cast iron pipe mechanized cleaning and dedusting device includes a support mounting plate 1 arranged horizontally, a lifting mounting plate 4 is horizontally arranged directly above the support mounting plate 1, and the four corners of the support mounting plate 1 are all vertical A hydraulic lifting column 3 is provided, and the upper ends of the hydraulic lifting column 3 are connected with the lifting installation plate 4, and the middle position of the lifting installation plate 4 is longitudinally provided with a limit guide groove 19, and a movable installation plate 5 is longitudinally arranged in cooperation with the limit guide groove 19, The support mounting plate 1 facing the limit guide groove 19 is equipped with a steering mounting column 7 symmetrically. 1 is connected, and the support mounting plates 1 on both sides of the steering mounting cylinder 9 are horizontally provided with a guid...

Embodiment 2

[0025] On the basis of Embodiment 1, the guide installation cylinder is installed in conjunction with the steering installation cylinder 9, and fixed by the fixing stud, so that the upper fixed installation plate 11 and the rotating clamping plate 14 can be interchangeably replaced, and the lifting device is suitable for different sizes. The support of gray cast iron dedusting extends its operating range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com