Secondary drying chamber gas distribution device used for producing SCR denitration catalyst

A technology of gas distribution device and denitrification catalyst, which is applied in the field of denitrification catalyst, and can solve the problems of excessive temperature fluctuation, low yield, uneven drying temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment.

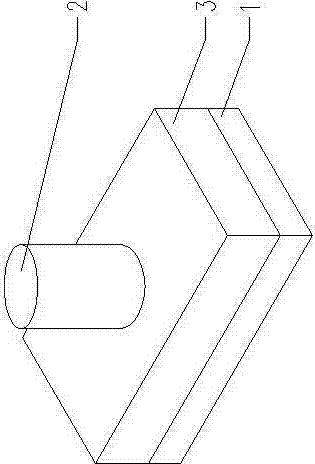

[0009] exist figure 1 Among them, the dry gas distributor 3 has a circular dry gas outlet 2 on it, and a square inlet 1 for the catalyst dry gas on the bottom. After heat transfer with the catalyst, the drying gas exits the catalyst channel and enters the square inlet 1 of the catalyst drying gas, and enters the drying gas distributor 3. After passing through the gas distributor, the drying gas flow rate slows down and the contact time with the catalyst is prolonged, and the drying temperature is uniform. It will cause the temperature of the catalyst to fluctuate too quickly after drying, the catalyst will be heated evenly, and the yield will be high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com