Detection method of mechanical failure

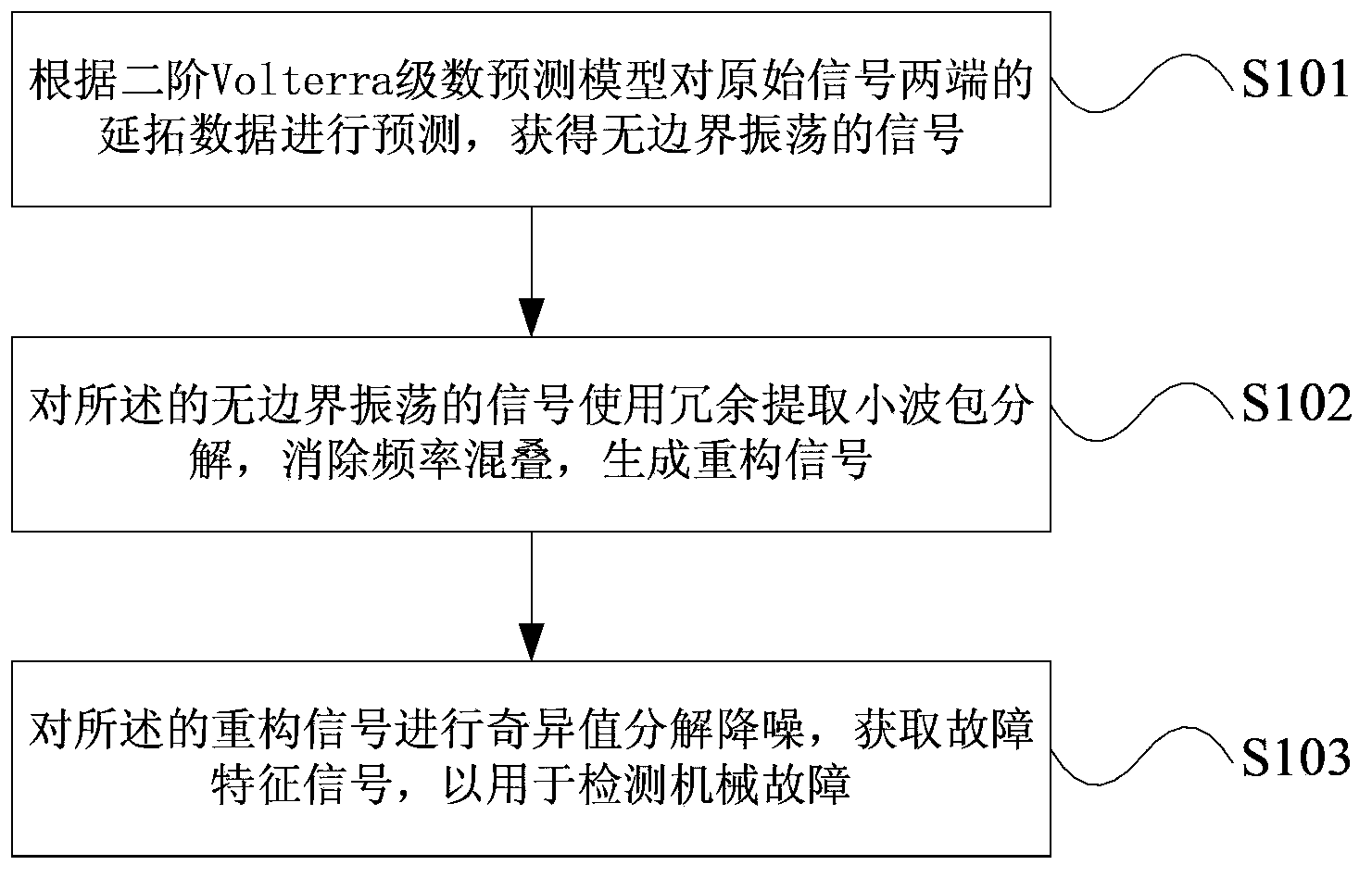

A detection method and technology for mechanical faults, which are applied in the field of weak detection of mechanical faults, obtain weak characteristic signals from mechanical fault signals, and can solve problems such as frequency aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

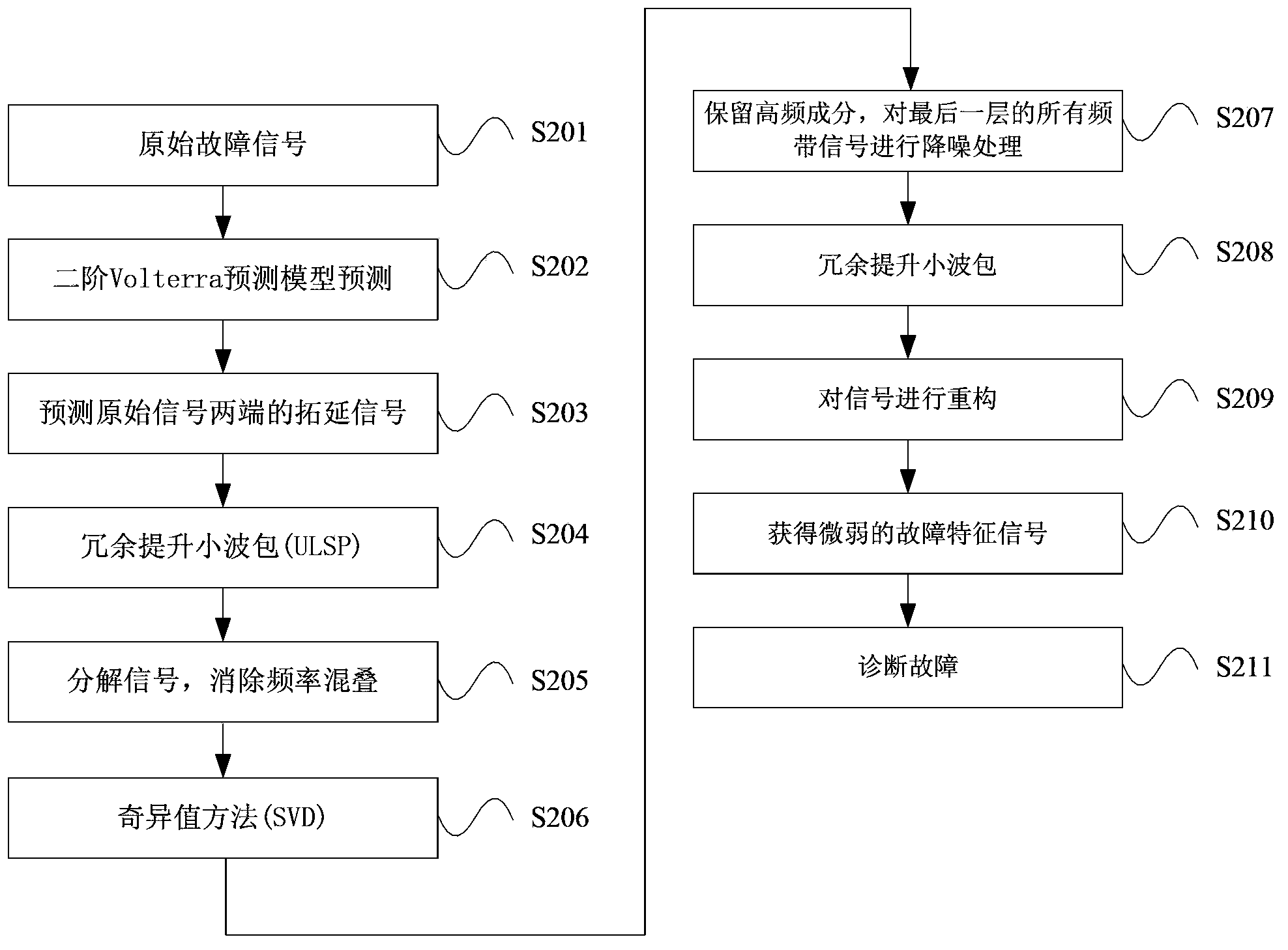

Method used

Image

Examples

Embodiment 1

[0146] Embodiment 1 (fault detection of reciprocating pump):

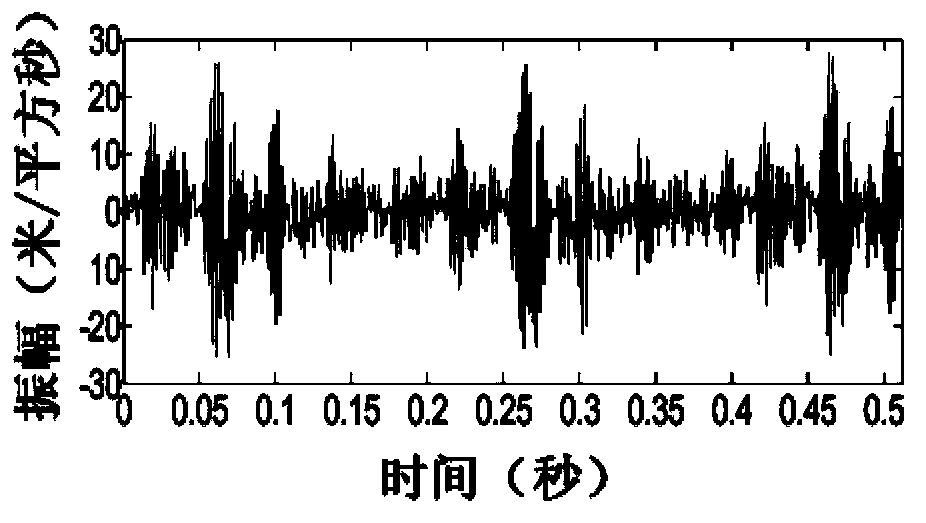

[0147] Taking the reciprocating water injection pump (model 5ZB-20 / 43) in Tarim Oilfield as an example, the method provided by the present invention will be described in detail below. The conveying medium of the reciprocating water injection pump is clean water and sewage. The motor drives the crankshaft to run through the pulley. The rated speed of the crankshaft is 300rpm (that is, the period per revolution is 60 / 300=0.2s) (Note: This data is used for final verification, see Figure 4A ). The data acquisition system consists of three parts, which is the self-developed EDCS-4 type. The acceleration vibration signal X(n) measured on the surface of the cylinder liner (substitute into formula (1)), the sampling length is n=8192 (substitute into formula (1)), and the sampling frequency is 16kHz (to be used in the calculation process, such as Figure 3A When drawing a time domain diagram, sampling length / sampling fre...

Embodiment 2

[0150] Embodiment 2: (fault detection of motor):

[0151] Taking the water injection centrifugal pump in Tarim Oilfield as an example, the method provided by the present invention will be described in detail below. The water injection centrifugal pump is driven by a three-phase asynchronous motor, the model is YKK630-2, the rated power is 1250kW, and the rated speed is 3000fmin. The bearings at both ends of the motor are sliding bearings, and the bearing model is DQ14-160B. The acceleration sensor is installed in the vertical direction of the bearing seat at the load end of the motor, the sampling frequency is 16kHz, and the sampling length is 2048 points. During a test, it was found that the vibration at the load end of the motor was too large, and the time domain and frequency domain of the original vibration were as follows: Figure 5A with Figure 5B shown. It can be seen that the main frequency component of the vibration is 50Hz, but it cannot be judged whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com