Device and method for checking defects on lower surface of steel plate on line

A steel plate and defect technology, which is applied in the field of on-line inspection devices for defects on the lower surface of steel plates, can solve problems such as identification, quality defects of finished steel plates, relationship safety and reliability, etc., achieve high efficiency, fast inspection speed, and reduce production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

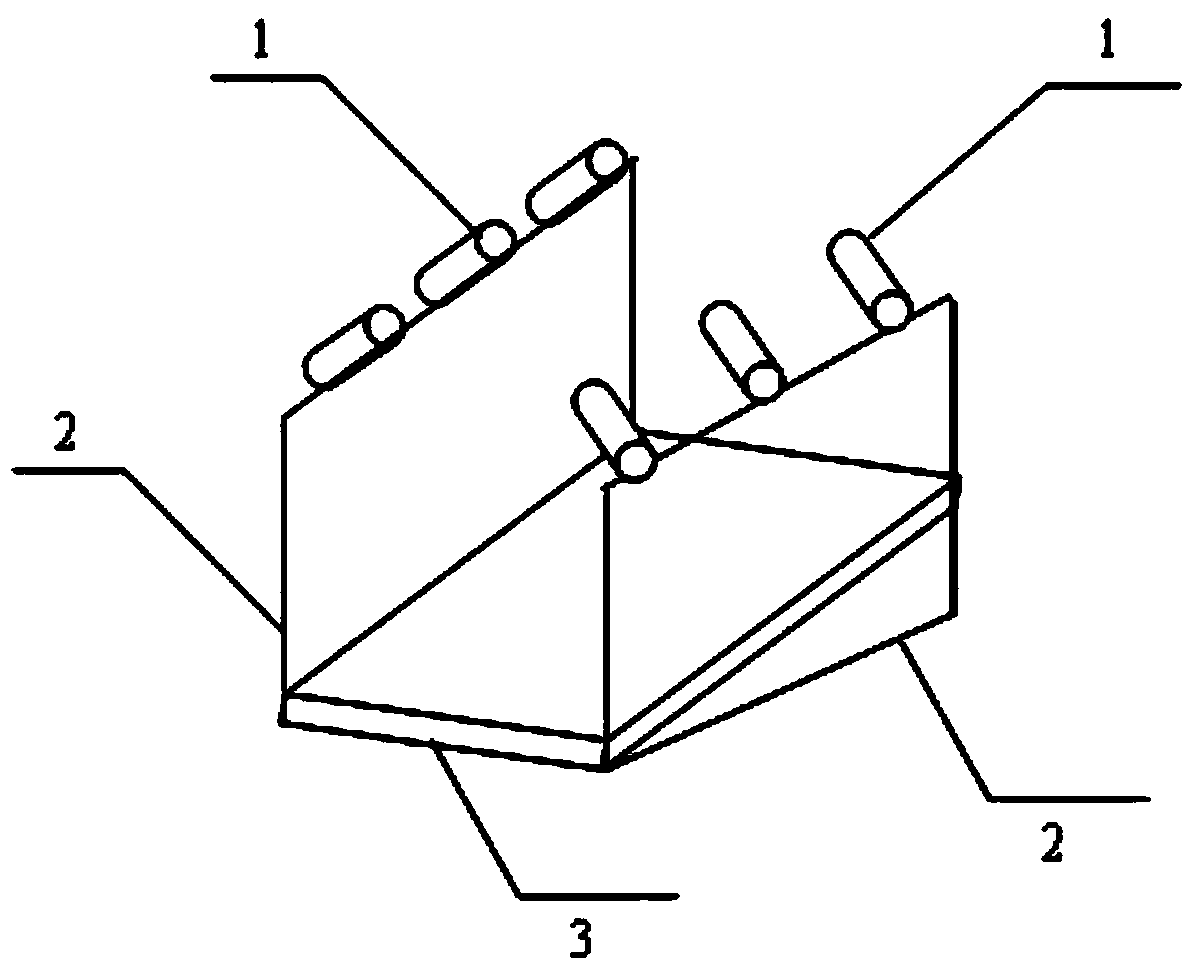

[0019] Such as figure 1 As shown, an online inspection device for defects on the lower surface of a steel plate includes a searchlight 1, a support frame 2 and a glass mirror 3. The two support frames 2 are respectively arranged on both sides of the glass mirror 3, and the searchlight 1 is arranged on two sides below the roller table. side.

[0020] The number of searchlights 1 on each side is 3 to 5.

[0021] The axis of the searchlight 1 is inclined upward at 15° to 20° with the horizontal plane.

[0022] The glass mirror 3 is 1-3 meters long and 4-6 meters wide.

[0023] Described glass mirror 3 forms 30 ° of angles with ground.

[0024] What support the glass mirror 3 is a steel structure support frame.

[0025] The method for checking the defects on the lower surface of the steel plate is as follows:

[0026] 1) Before the steel plate is put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com