Test method for battery thermal runaway characteristics

A test method and technology of thermal runaway, applied in the direction of measuring electricity, calorimeter, measuring device, etc., can solve the problem of inability to accurately find the starting point of sample exotherm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

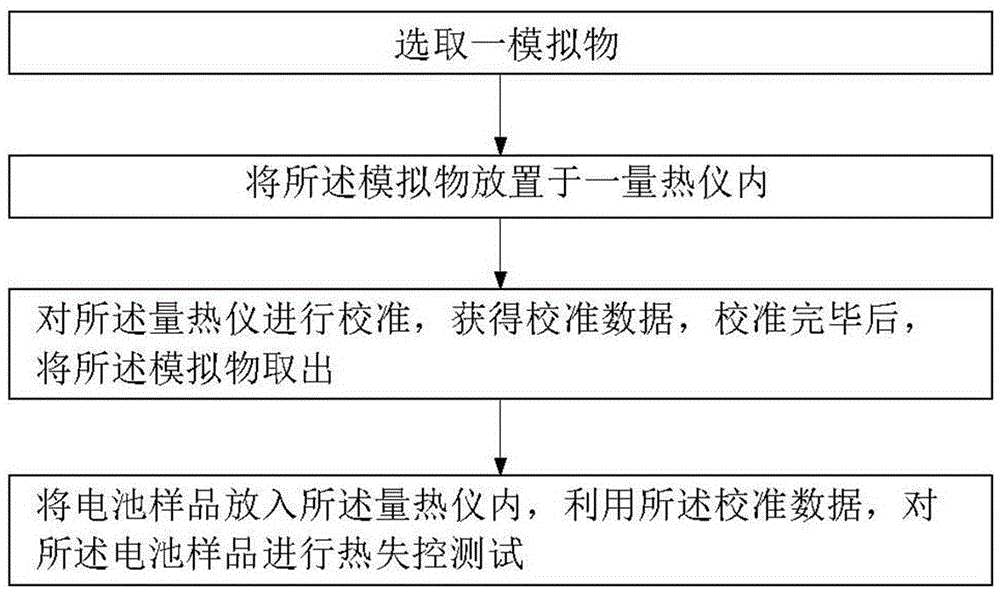

[0031] The method for testing the thermal runaway characteristics of the battery provided by the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

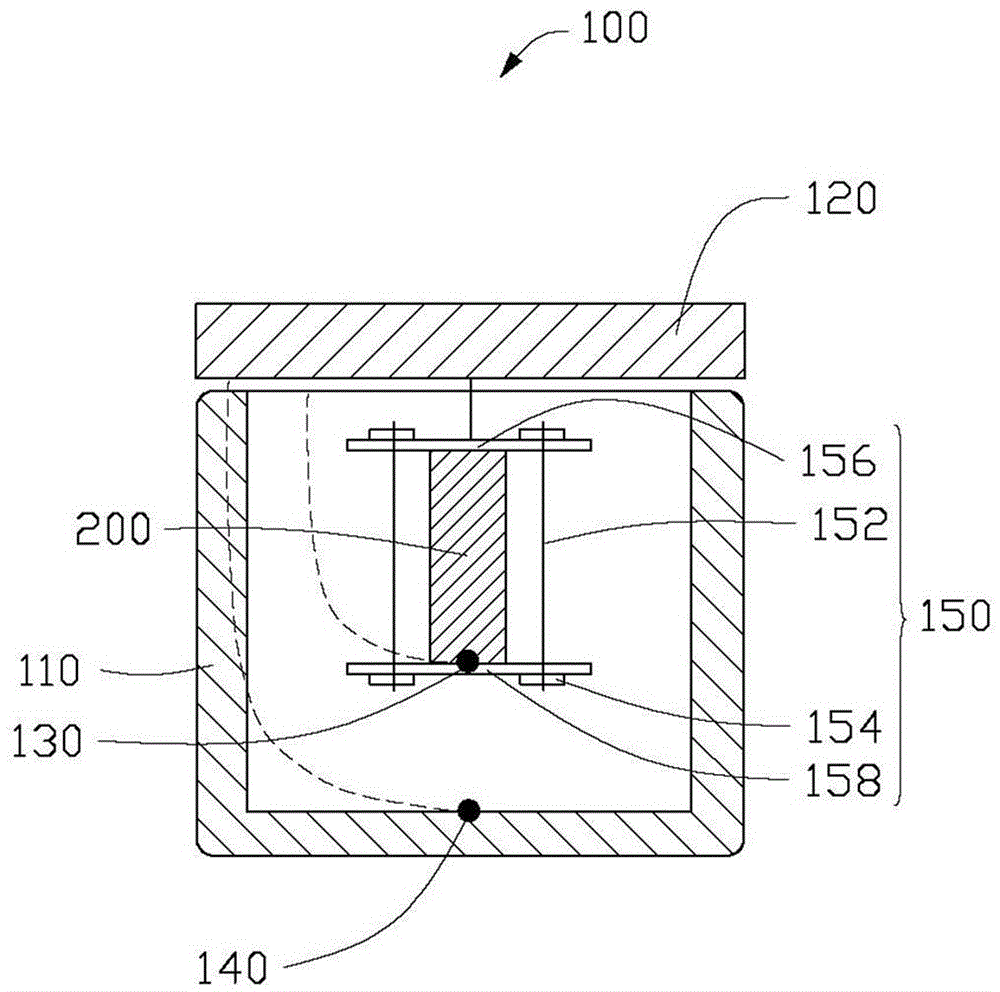

[0032] see figure 1 , a calorimeter 100 includes a calorimetric cavity 110, a top cover 120, a first temperature sensor 130 and a second temperature sensor 140, the first temperature sensor 130 is used to monitor the temperature of the surface of the battery sample to be tested, The second temperature sensor 140 is used to monitor the temperature of the calorimetry cavity 110 . In the embodiment of the present invention, a large-scale accelerated calorimeter EV-ARC produced by British THT Company is used to conduct a thermal runaway test.

[0033] The calorimeter further includes a fixing bracket 150 for fixing the battery sample to be tested, and the fixing bracket 150 can be hoisted on the top cover 120 . The fixing bracket 150 includes a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com