Auxiliary Method for Programming of NC Machine Tool

A technology of CNC machine tools and blades, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve problems such as difficult to obtain qualified products, achieve the effect of accurate coordinates, accurate product dimensions, and save calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the drawings and embodiments.

[0028] A programming assistance method for CNC machine tools, including the following steps:

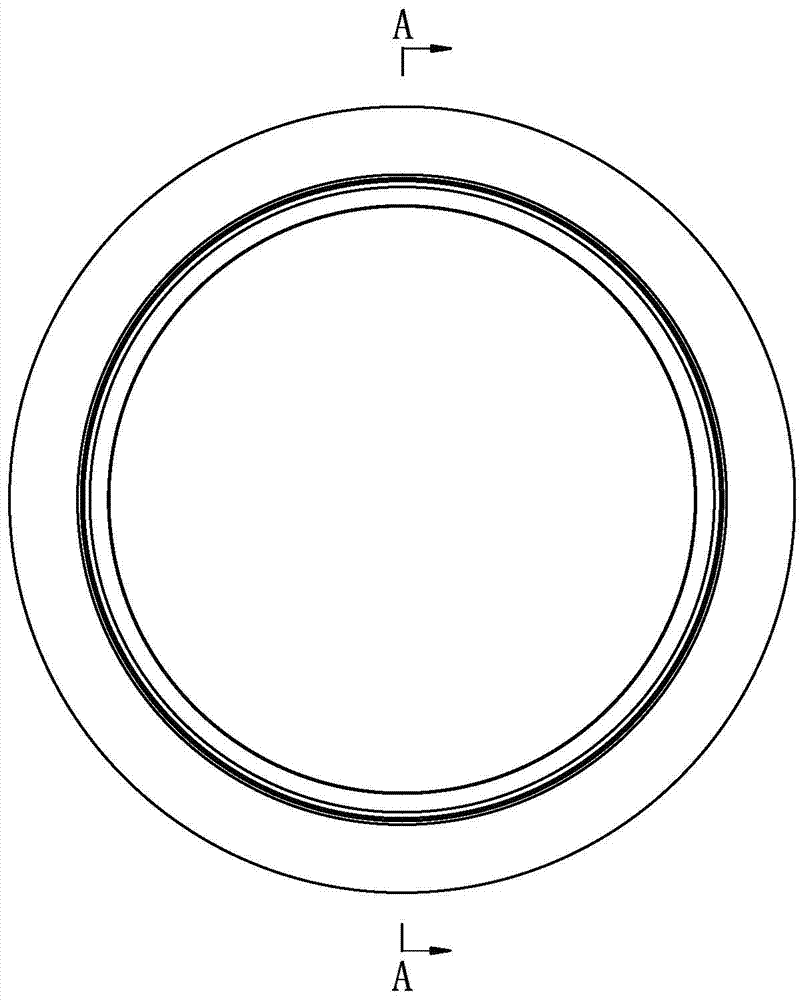

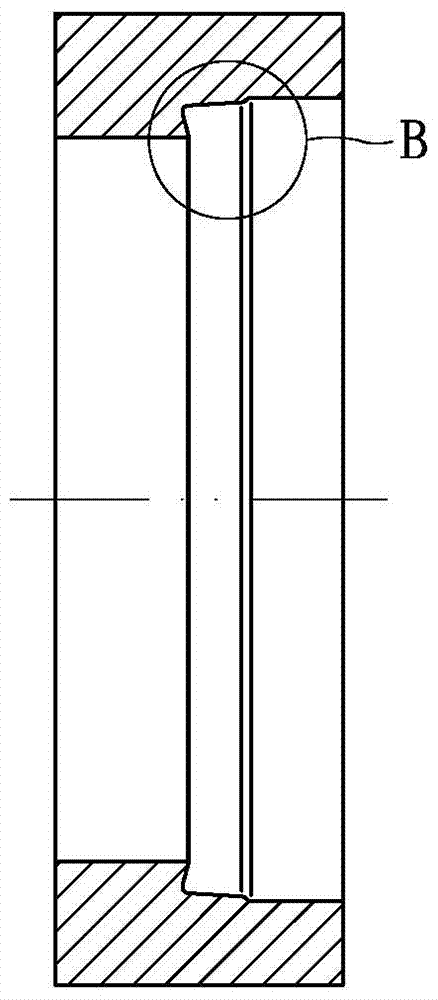

[0029] S1. Draw accurate AUTO CAD graphics through AUTO CAD software according to the structure of the product to be processed. The graphics ratio of AUTOCAD graphics is 1:1;

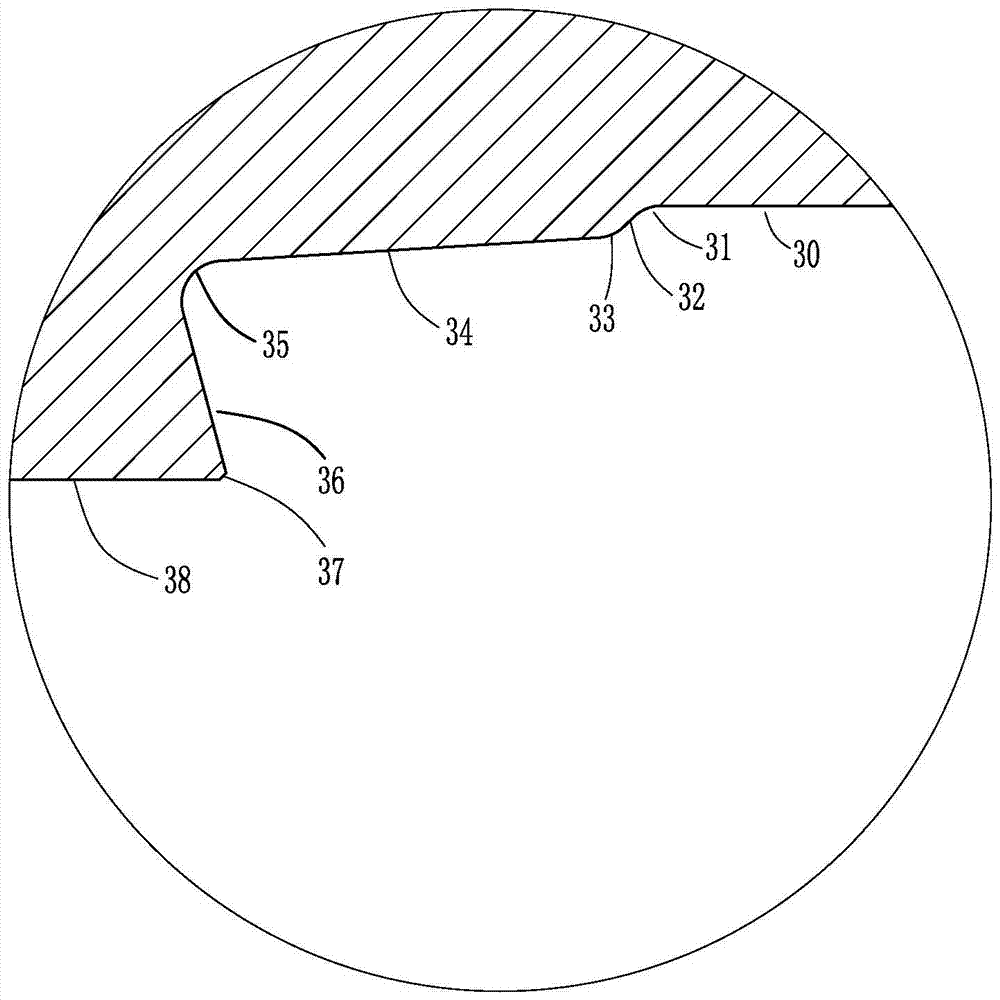

[0030] S2. According to the tool nose radius, the included angle of the tool nose and the included angle between the blade and the spindle of the CNC machine tool used for processing, the blade graphics are drawn at a ratio of 1:1 through AUTO CAD software;

[0031] S3. Place the drawn multiple blade graphics in the AUTO CAD software at the key points on the drawing drawn in step S1. The cutting surface of the blade on the drawing is tangent to the processing surface of the product to be processed, and each key point It is the starting point and end point of the blade track when processing different process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com