bp Global Optimal Propylene Polymerization Production Process Optimal Soft Sensing Instrument and Method

An optimal soft-sensing, propylene polymerization technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low measurement accuracy and easy to be affected by human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

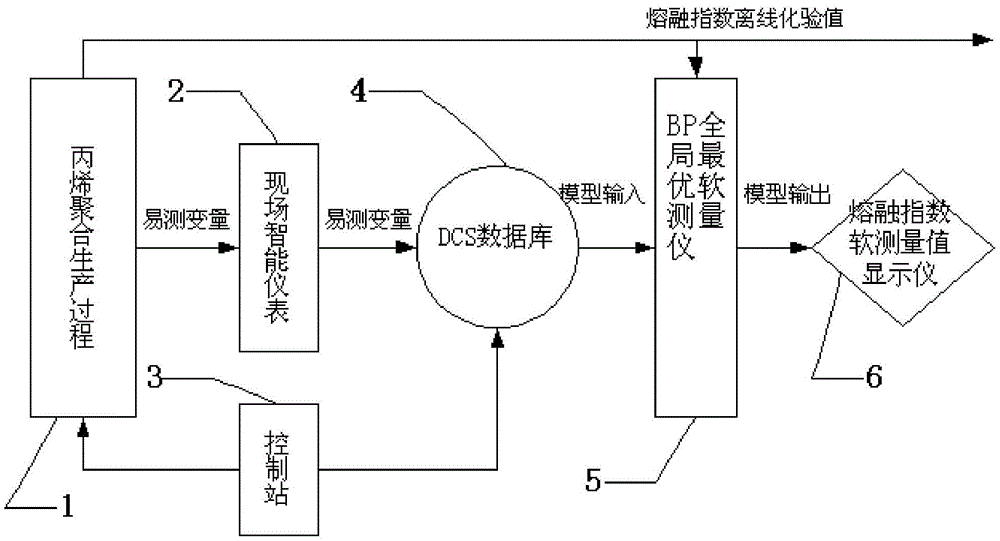

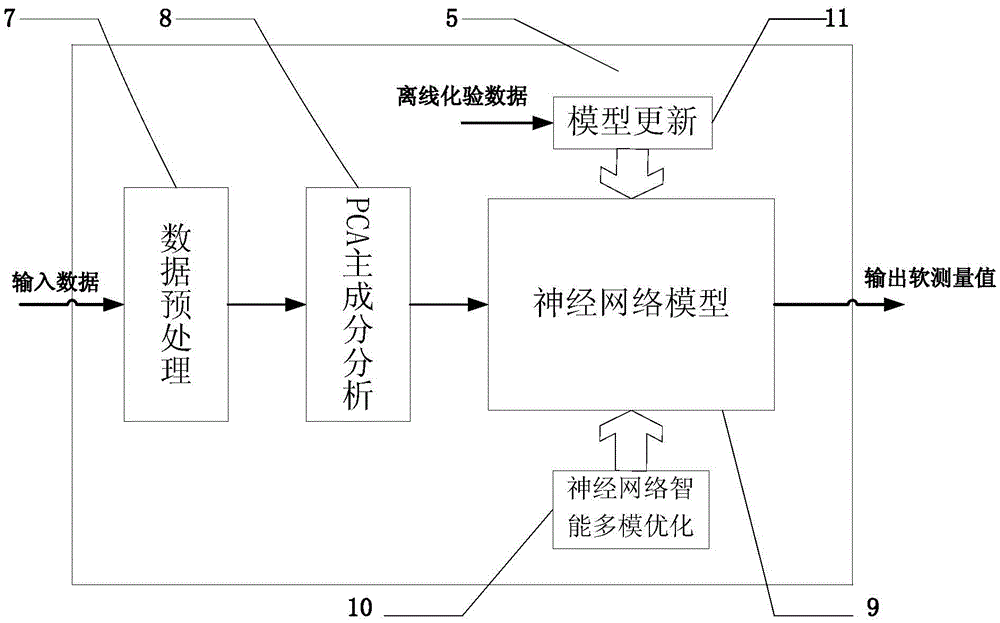

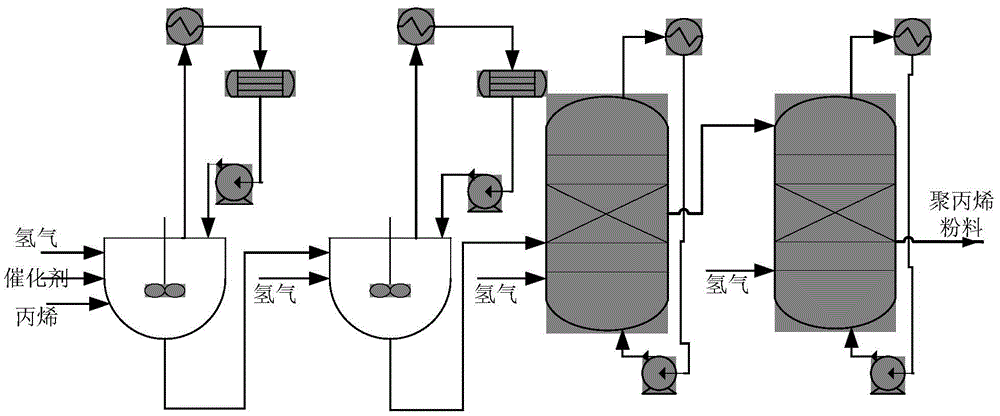

[0082] 1. refer to figure 1 , figure 2 with image 3 , a BP globally optimal soft measuring instrument for propylene polymerization production process, including propylene polymerization production process 1, on-site intelligent instrument 2 for measuring easily measurable variables, control station 3 for measuring operating variables, and DCS for storing data Database 4, BP global optimal soft sensor 5 and melt index soft sensor value display 6, the on-site intelligent instrument 2, the control station 3 are connected to the propylene polymerization production process 1, the on-site intelligent instrument 2, the control station 3 and the The DCS database 4 is connected, and the DCS database 4 is connected with the input end of the BP global optimal soft sensor 5, and the output end of the BP global optimal soft sensor 5 is connected with the melting index soft sensor value display instrument 6, and the BP global optimal soft sensor includes:

[0083] (1) The data preproc...

Embodiment 2

[0155] 1. refer to figure 1 , figure 2 with image 3 , a BP global optimal propylene polymerization production process optimal soft-sensing method includes the following steps:

[0156] (1) For the propylene polymerization production process object, according to the process analysis and operation analysis, the operational variables and easily measurable variables are selected as the input of the model, and the operational variables and easily measurable variables are obtained from the DCS database;

[0157] (2) Preprocess the sample data, center the input variables, that is, subtract the average value of the variables; and then perform normalization processing, that is, divide by the change interval of the variable value;

[0158] (3) The PCA principal component analysis module is used to pre-whiten the input variables and de-correlate the variables. It is realized by applying a linear transformation to the input variables, that is, the principal components are obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com