A temperature control system for liquid analysis

A technology of temperature control system and liquid analysis, which is applied in the direction of temperature control, electric temperature control, control/regulation system, etc. It can solve the problems of low battery efficiency, slow heating speed, difficulty, etc., and achieve low energy consumption accuracy, The effect of rapid temperature rise and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

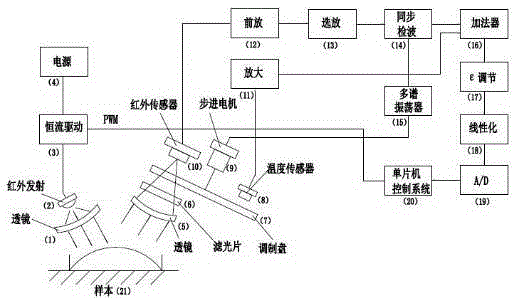

[0008] The present invention is described in detail below in conjunction with each figure:

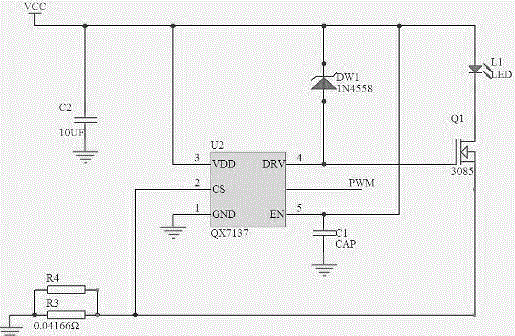

[0009] pass figure 1 As can be seen from the block diagram, the present invention is made up of two parts, and one is the heating system that is made up of infrared emission tube (2) and the control system that is made up of infrared sensor (10), is placed with emitting device in front of infrared emission tube (2) The lens (1) can evenly diffuse the infrared light emitted by the infrared emitting tube (2) to the entire sample (21) area. The infrared emitting tube (2) uses an infrared light-emitting LED tube. This infrared emitting tube (2) has High efficiency, so its own temperature rise is very low. The constant current drive (3) is used to power the infrared emission tube (2). The constant current drive (3) uses the QX7137 chip of Quanxin Electronics. The chip has PWM regulation. function, can accept the PWM control signal fed back by the single-chip microcomputer control system (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com