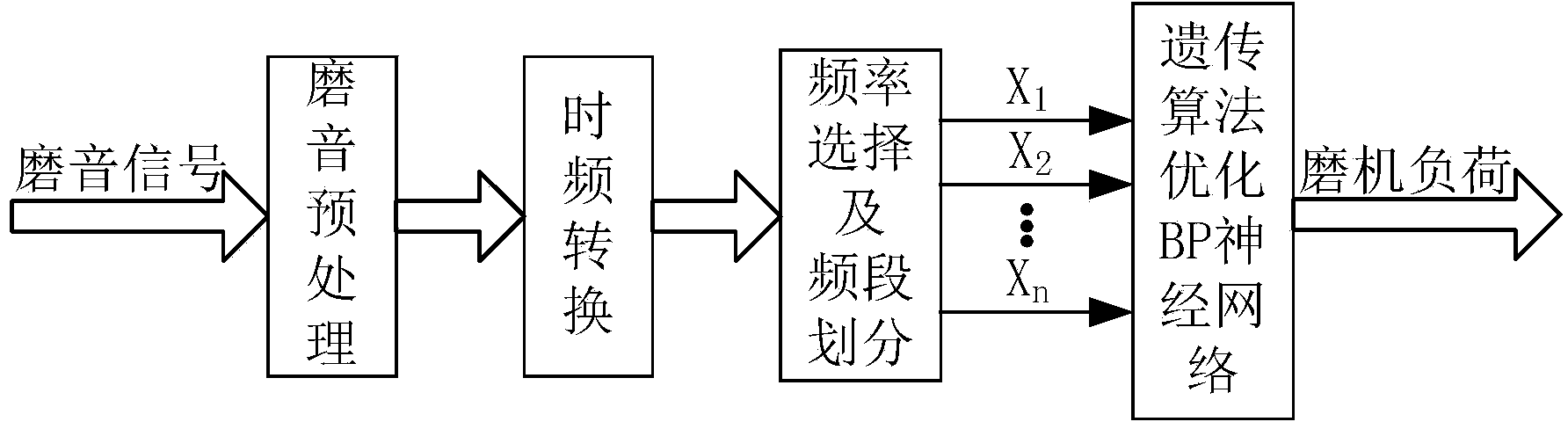

Ball grinding mill load detecting method for optimizing BP neural network based on genetic algorithm

A technology of BP neural network and genetic algorithm, applied in the field of ball mill load detection based on genetic algorithm optimization of BP neural network, can solve the problems of low accuracy, waste, large error, etc., achieve strong adaptability, improve automatic control, and facilitate Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049]For load prediction of the wet ball mill in the mining plant, a medium-sized mill of Φ3.6m×4m is used, the diameter of the steel ball is about 70mm, the ore is fine-vein disseminated molybdenum ore, and the speed is 18-22r / min; 16-bit single-channel sampling is adopted. The sampling frequency is 44100Hz, and the implementation steps are as follows:

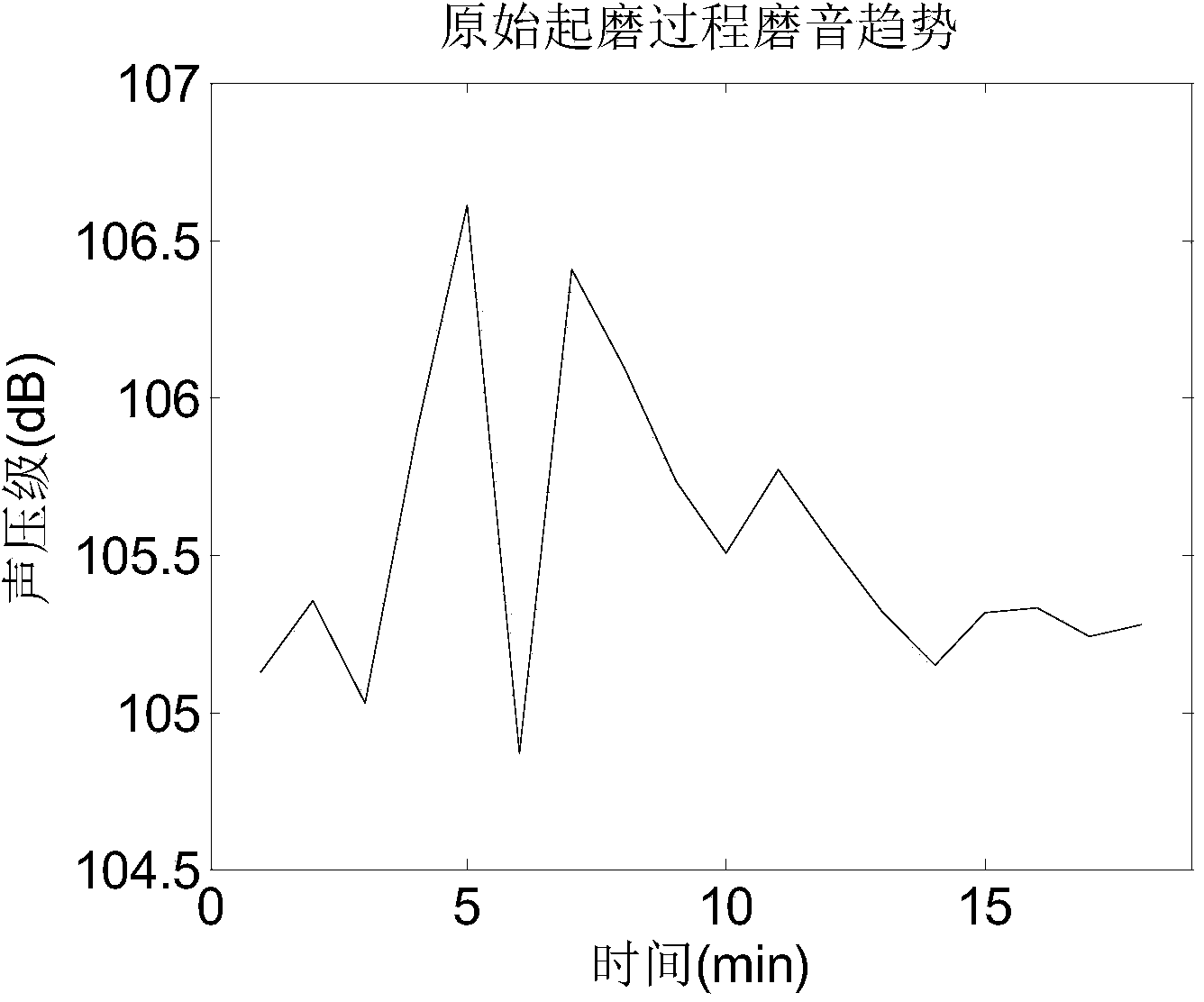

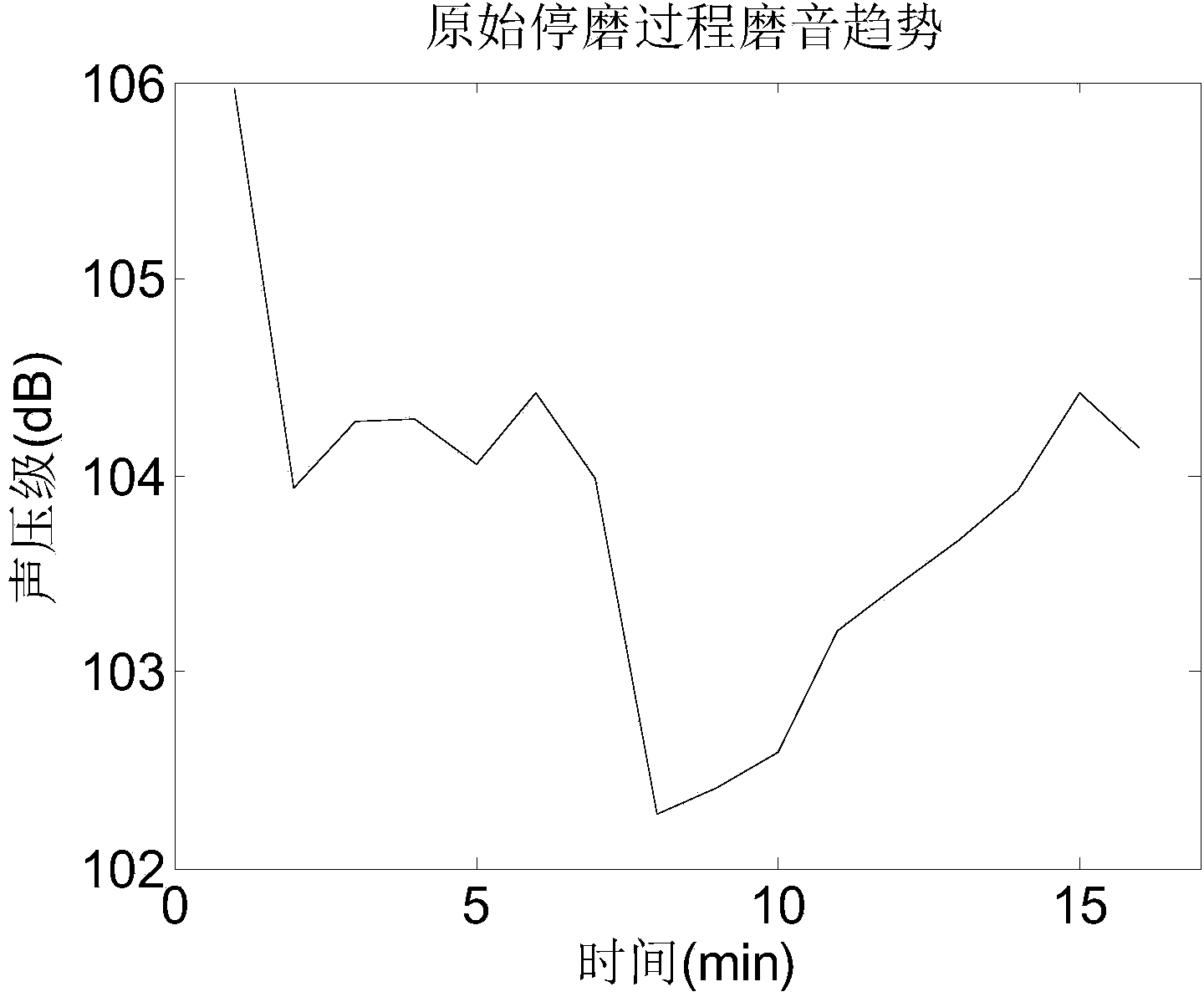

[0050] Step 1: Collect the grinding sound of starting grinding for 20 minutes and grinding sound of stopping grinding for 18 minutes;

[0051] Step 2: Pinch the beginning and end of the grinding sound and stop grinding sound, add Hamming window processing, and then perform fast Fourier transform on each windowed data segment, and the number of Fourier transform points is N FFT = 44100 × 60 = 2646000, take the square of each transformation result, and divide it by the number of fast Fourier transform points as an estimate of the power spectrum estimate; then convert this estimate into a sound pressure level; get figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com