Purging method for signal reception optical window of online laser analyzer

A laser analyzer and signal receiving technology, which is applied in the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc. It can reflect the real oxygen content of the measured medium and the delay of the response time of the load-line analysis system, so as to achieve the effect of improving the level of automatic control and management, reducing the maintenance workload and having a long operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

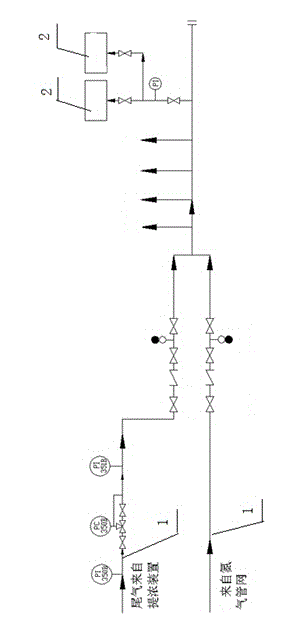

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

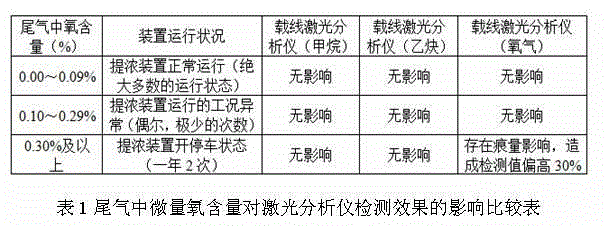

[0027] The selected purge gas source must meet the following conditions: 1. The gas source medium is clean, the supply is stable, and the process indicators such as pressure and flow temperature meet the requirements; 2. After the purge medium is used in the system, it will not enrich the downstream 3. The gas source is cheap and suitable for long-term use; 4. The gas will not affect the accuracy of detection after purging the laser analyzer. After extensive screening, it was decided to use the by-product tail gas of the downstream enrichment unit instead of nitrogen as the source of purge gas.

[0028] The main components of the by-product tail gas of the enrichment unit are: H 2 The content is about 50%~65%, the CO content is about 20%~35%, the CH 4 The content is about 3% to 4%, a small amount of other alkynes, a small amount of nitrogen, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com