Regeneration process of sulfur-containing waste alkali liquor

A technology for sulfur waste lye and waste lye, which is applied in the field of regeneration technology of sulfur-containing waste lye, can solve the problems of secondary environmental pollution, poor economic benefits, huge investment in processing equipment, etc., and achieves large specific surface area and adsorption capacity. Strong, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

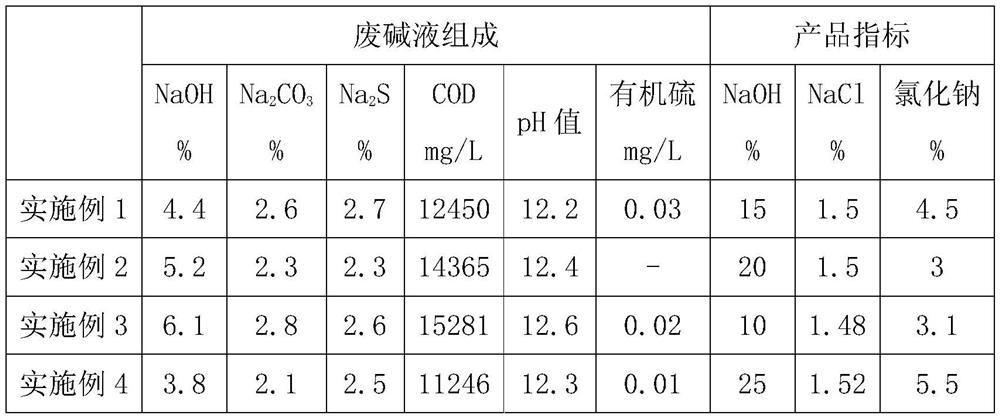

[0068] (1) The composition of waste lye produced by cracking method: sodium hydroxide 4.4%, sodium carbonate 2.6%, sodium sulfide 2.7%, COD12450mg / L, pH12.2, organic sulfur 0.03mg / L.

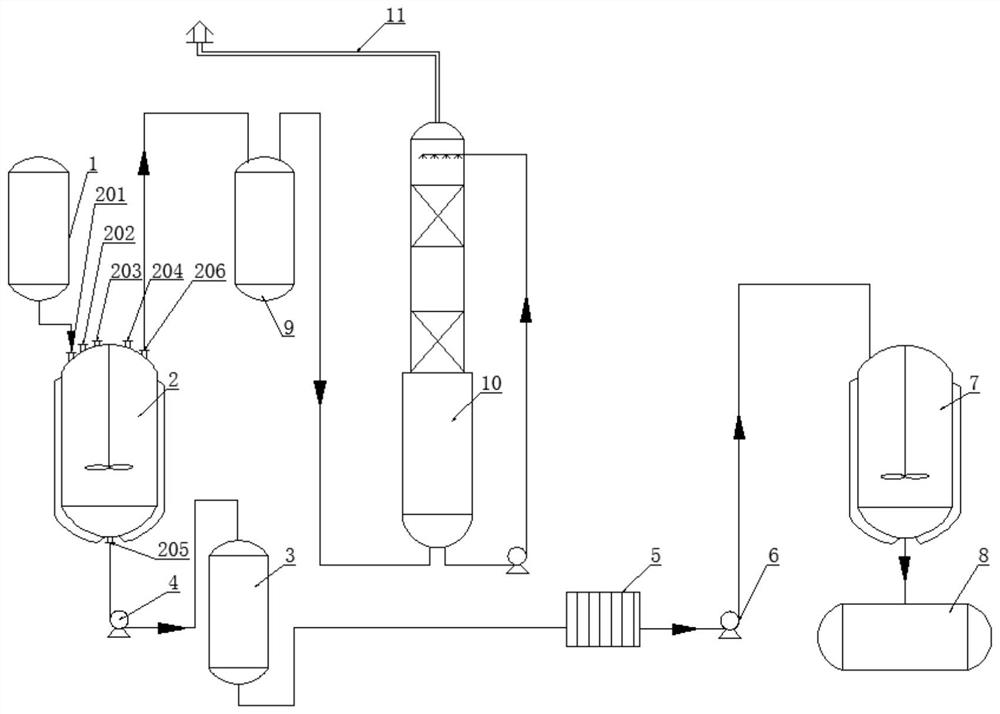

[0069] (2) As shown in the figure, the regeneration system of sulfur-containing waste lye is adopted, the system has an acidification tank 1 and an acidification kettle 2, and the acidification kettle 2 is provided with a waste acid inlet 201, an oxidant inlet 202, and a flocculant inlet 203, waste lye inlet 204, acidification waste lye outlet 205 and waste gas outlet 206, the acidification tank 1 is connected with the waste acid inlet 201 of the acidification kettle 2 through a pipeline, and the acidification waste lye water outlet of the acidification kettle 2 is A sedimentation concentration tank 3, a centrifugal pump I4, and a filter press 5 are successively connected through pipelines, and the liquid outlet of the filter press 5 is connected with a decolorization kettle 7 through a pipeline,...

Embodiment 2

[0072] (1) The composition of the waste lye produced in the production of hydrogenated gasoline: 5.2% sodium hydroxide, 2.3% sodium carbonate, 2.3% sodium sulfide, COD14365mg / L, pH12.4;

[0073] (2) the regeneration system of the sulfur-containing waste caustic soda that adopts is the same as embodiment 1;

[0074] (3) Get 1000g of waste lye produced in the production of hydrogenated gasoline and put it into the acidification kettle 2, adjust the pH to 12 with concentrated sulfuric acid, add Na 2 S 2 o 8 35g, 0.5g of octanol, stir to dissolve, add 3.0g of cationic polyacrylamide solution with a mass concentration of 0.1%, and stir slowly for 30min; during the reaction process, waste gas containing hydrogen sulfide will be generated, which will enter the middle storage tank 9 through the waste gas outlet 206 , the exhaust gas containing hydrogen sulfide in the middle storage tank 9 enters the spray tower 10 from the bottom of the spray tower 10, and is sprayed with NaOH solu...

Embodiment 3

[0076] (1) Composition of sulfur-containing waste lye: 6.1% sodium hydroxide, 2.8% sodium carbonate, 2.6% sodium sulfide, COD 15281mg / L, organic sulfur 0.02mg / L, pH12.6;

[0077] (2) the regeneration system of the sulfur-containing waste caustic soda that adopts is the same as embodiment 1;

[0078] (3) Get 1000g of waste lye produced in the production of hydrogenated gasoline and pour it into the acidification kettle 2, adjust the pH to 11 with concentrated sulfuric acid, add Na 2 S 2 o 8 10g, 0.1g of octanol, stir to dissolve, add 0.1g of cationic polyacrylamide solution with a mass concentration of 0.1%, and slowly stir for 30min; during the reaction process, waste gas containing hydrogen sulfide will be generated, which will enter the middle storage tank 9 through the waste gas outlet 206 , the exhaust gas containing hydrogen sulfide in the middle storage tank 9 enters the spray tower 10 from the bottom of the spray tower 10, and is sprayed with NaOH solution with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com