Brushless direct current motor and commutation method thereof

A technology of brushed DC motors and commutators, which is applied in the direction of electronic commutators, electromechanical devices, electrical components, etc., and can solve problems such as large torque fluctuations, affecting the stability of motor operation, and limiting the application of brushless DC motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the embodiments shown in the accompanying drawings.

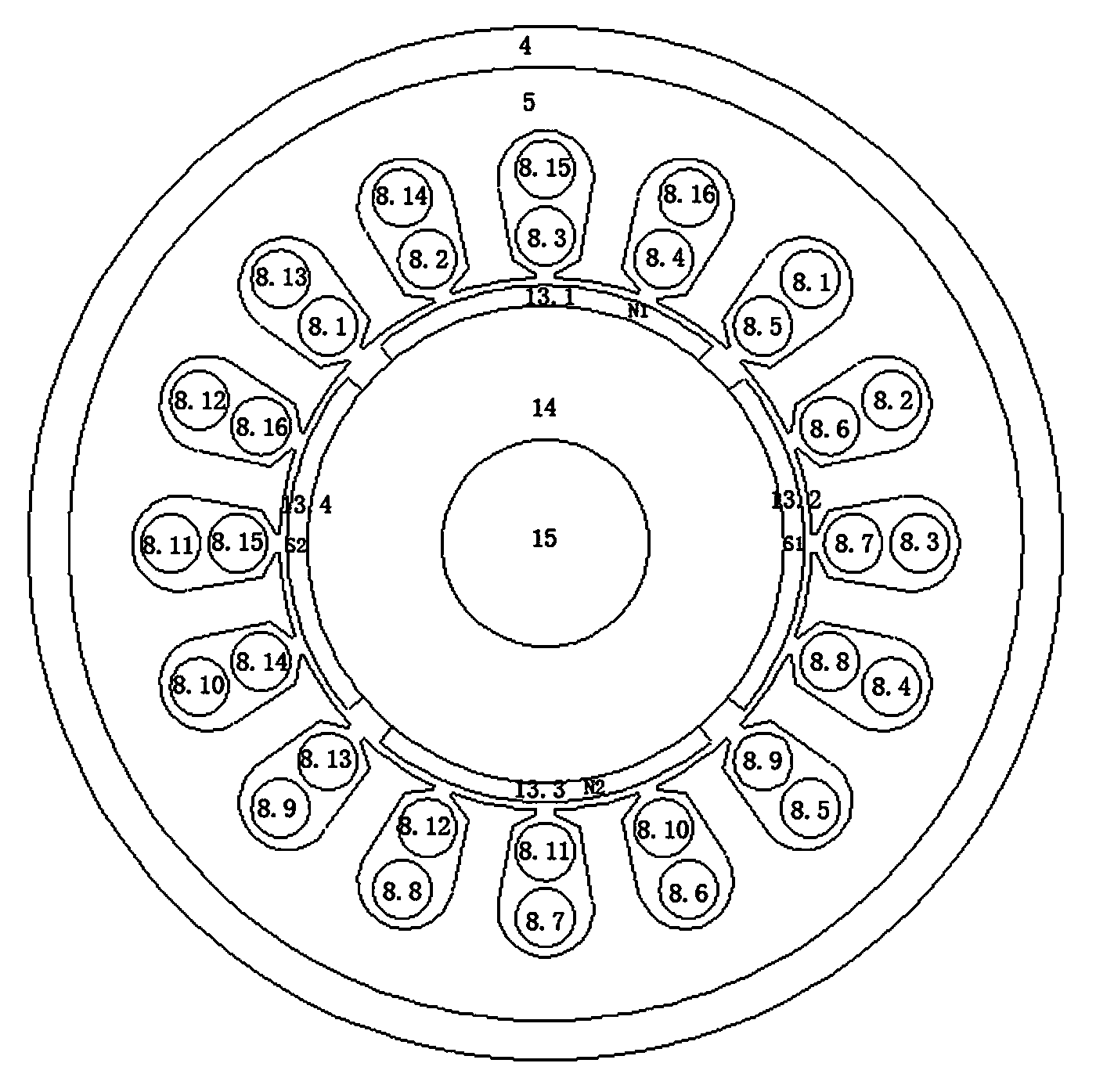

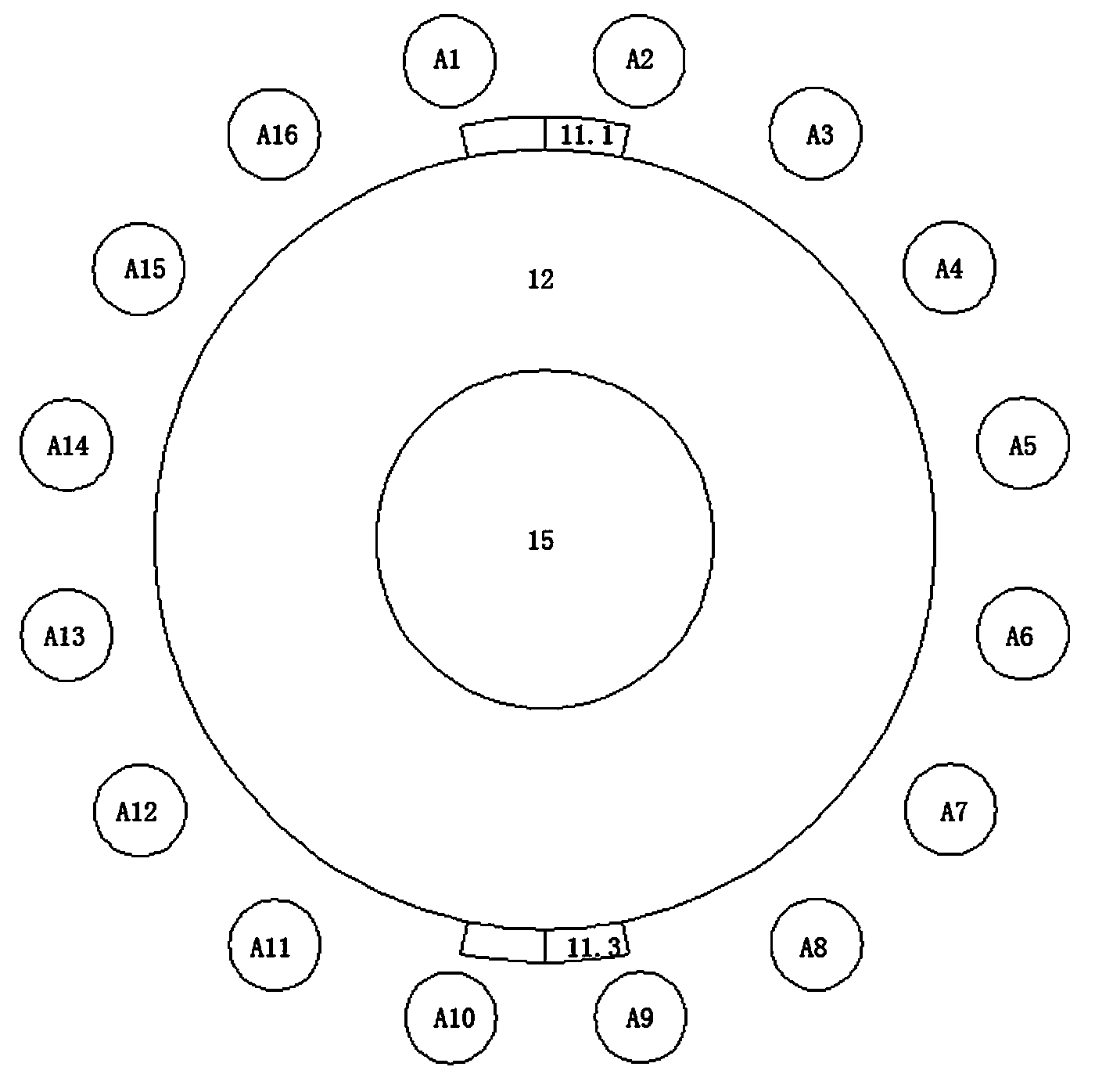

[0020] An embodiment of the present invention is a 4-pole 16-slot internal rotor brushless DC motor, such as figure 1 As shown, it includes end cover 1, bearing 2, fastener 3, casing 4, armature core 5, cooling fan 6, windshield 7, armature winding 8, electronic commutator 9, commutation element bracket 10 , Position indicating permanent magnet 11, position indicating permanent magnet support 12, rotor permanent magnet main pole 13, rotor core 14 and rotating shaft 15.

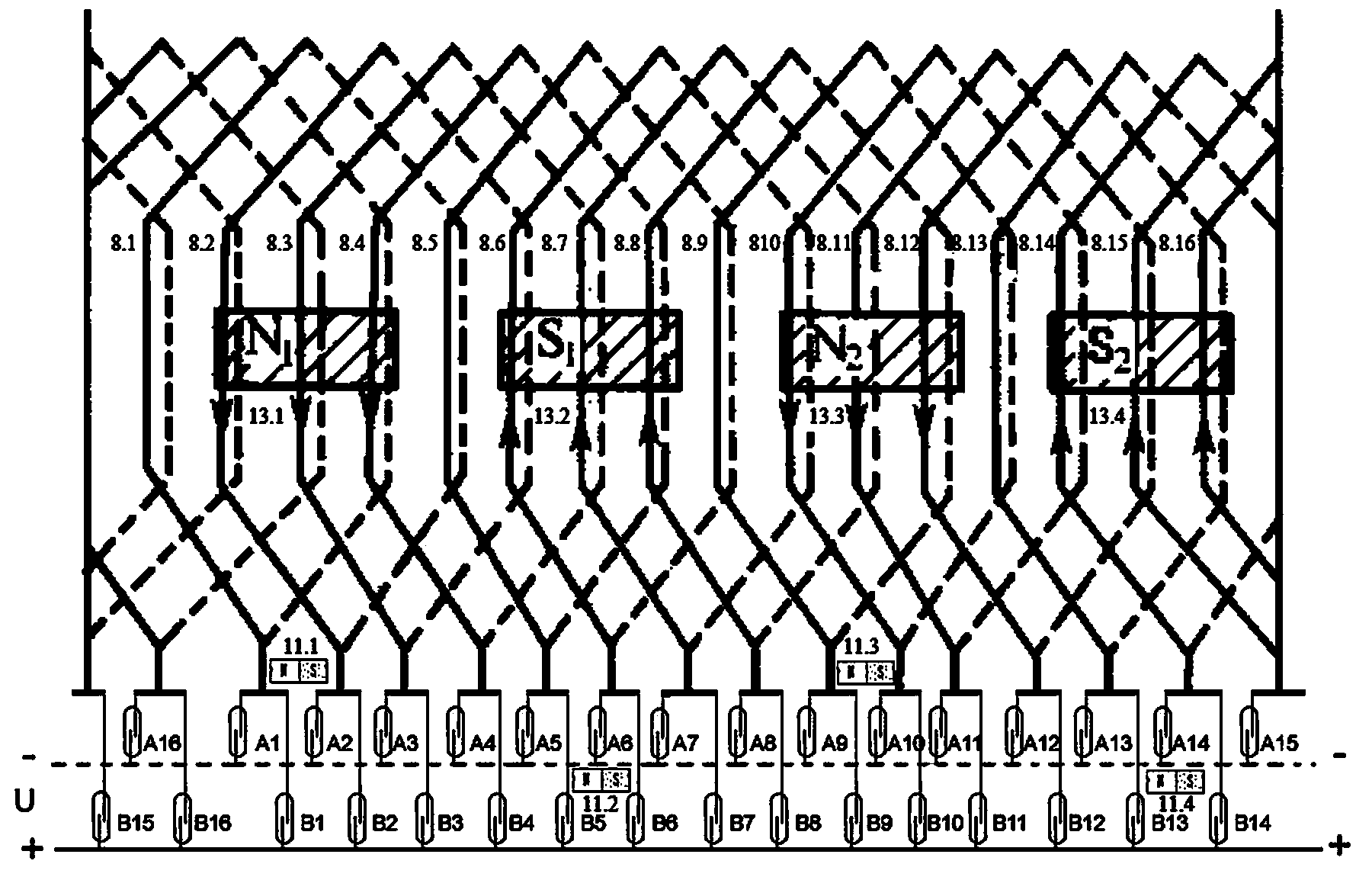

[0021] In the embodiment, the permanent magnet main pole 13 of the rotor is a four-pole surface-mounted structure, and the main permanent magnet pole 13 of the rotor is composed of N1, S1, N2 and S2 arranged alternately in polarity, respectively numbered 13.1, 13.2, 13.3, 13.4, Such as figure 2 shown. The rotor core 14 is made of thin silicon steel sheets or a whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com