Luminance real-time adjusting device of light source in pole piece surface defect detection and adjusting method thereof

A technology for light source brightness and defect detection, applied in light sources, electric light sources, lighting devices, etc., can solve problems such as difficulty in ensuring image quality, complex structure and algorithm, and achieve the effect of ensuring accuracy without affecting detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

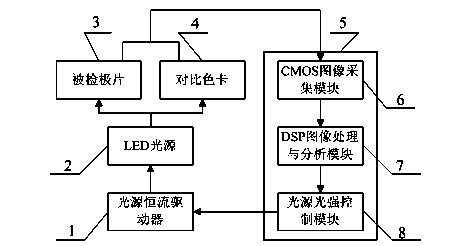

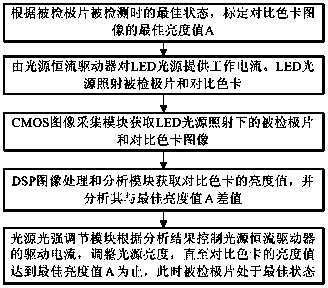

[0024] The real-time adjustment device and adjustment method of the brightness of the light source in the pole piece surface defect detection of the present invention will be further described in conjunction with specific implementation methods.

[0025] The LED light source includes a group of high-brightness LEDs, a PCB board and a housing. The LEDs are welded on the PCB board and assembled in the housing. There is a condenser prism outside the PCB.

[0026] The light source light intensity control module 8 is realized by a light source light intensity control circuit.

[0027] The contrast color card is a monochromatic gray scale card, the gray value of this card is similar to the color of the tested pole piece and is under the same light source as the tested pole piece. When the brightness changes, the contrast color card image collected by the camera changes synchronously with the gray value of the inspected electrode image, that is, the brightness change of the contrast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com