Transport plate for bagged goods

A technology for conveying plates and goods, applied in the field of conveying plates, it can solve problems such as peeling, bag or package rupture, pallets not forming a stable or rigid surface, etc., to achieve the effect of flat design, increased strength or rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

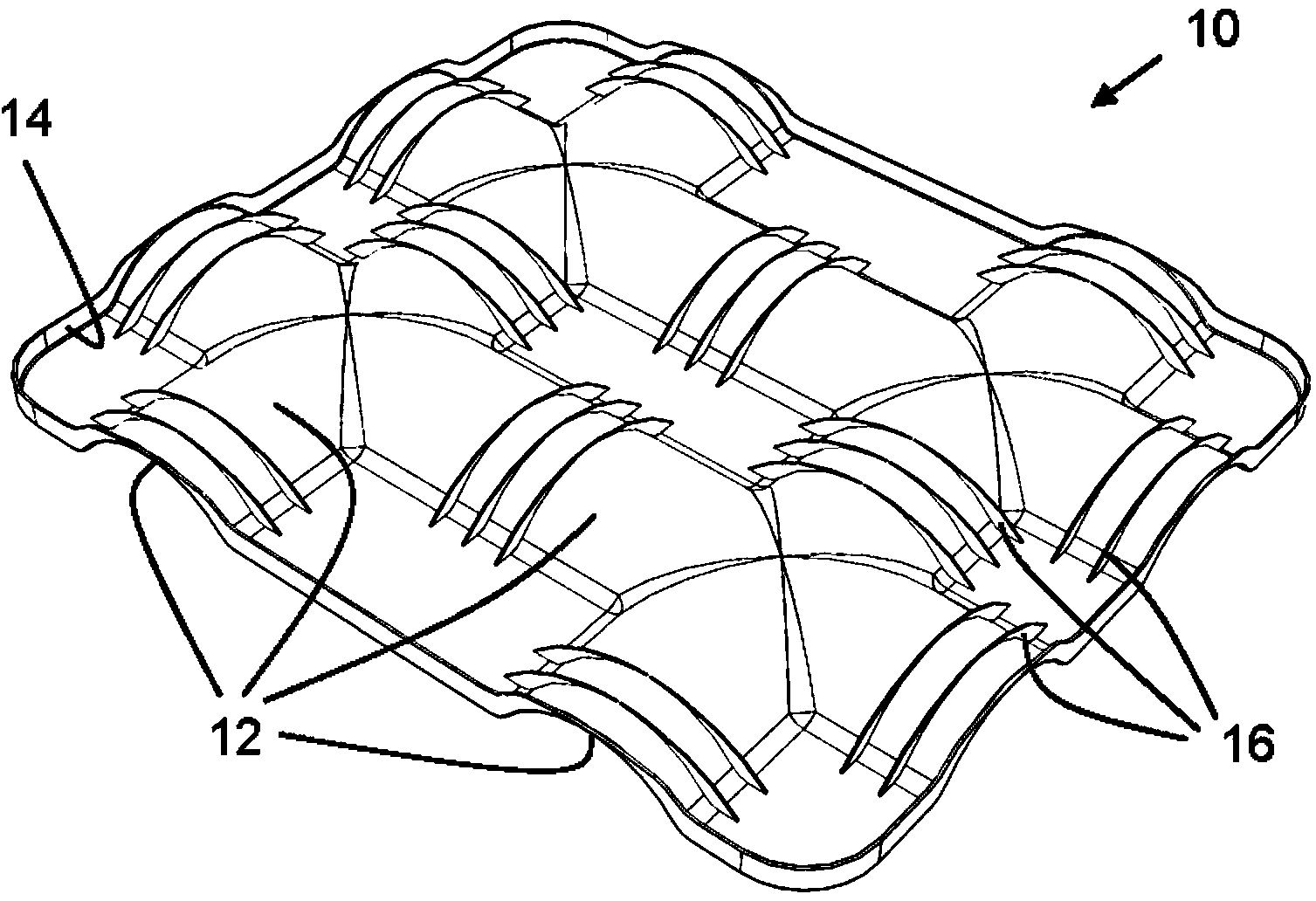

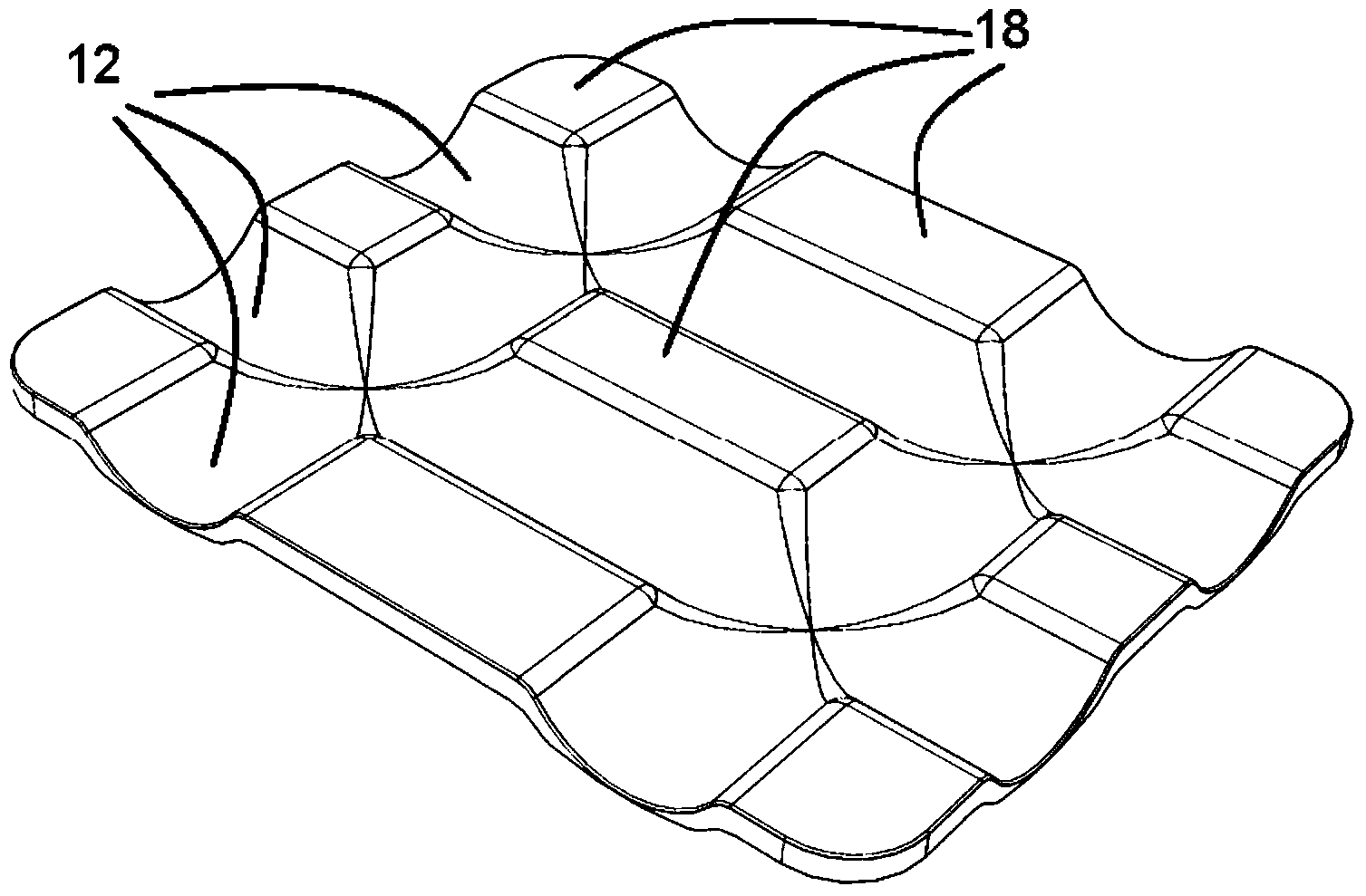

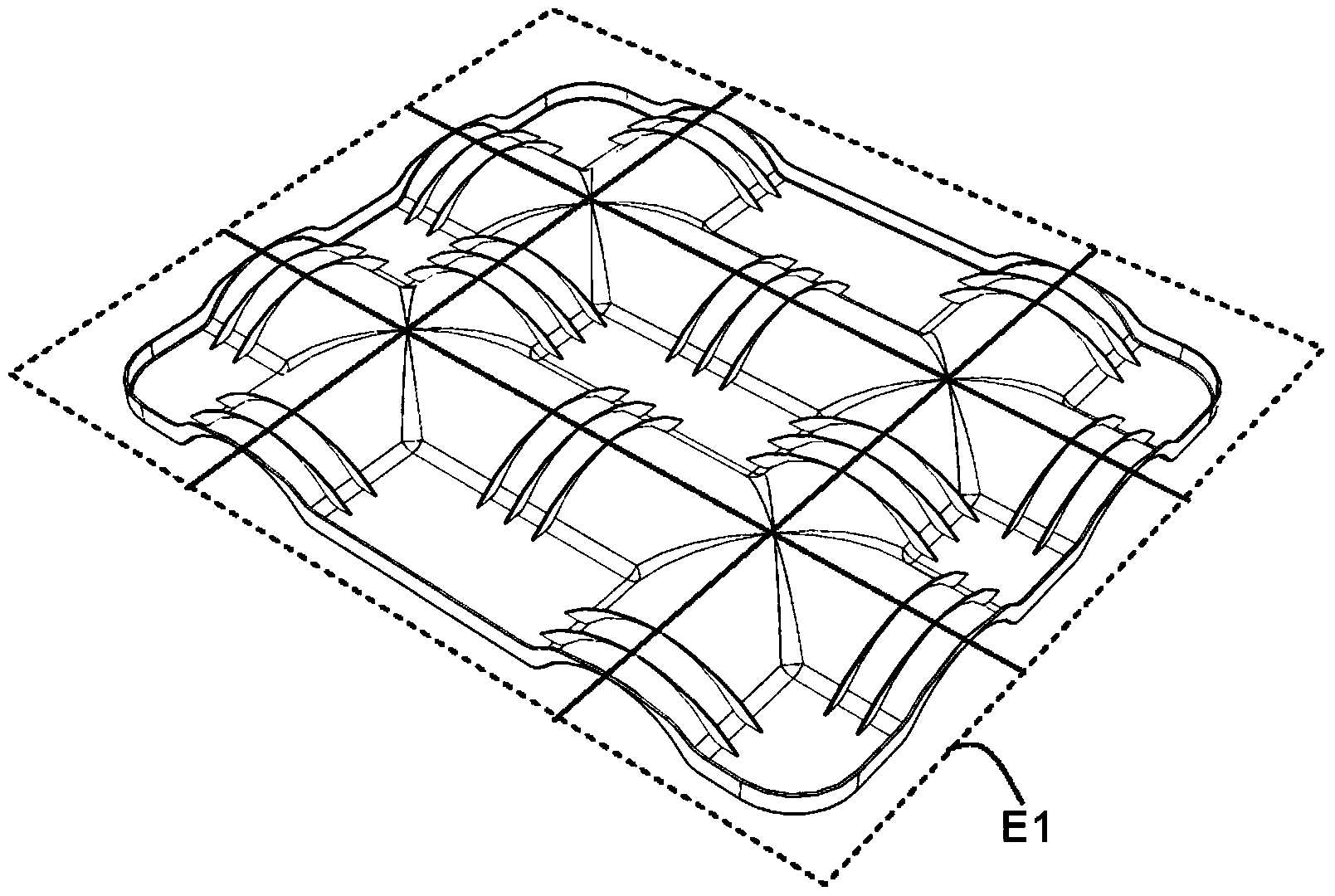

[0064] figure 1 Shown is a conveyor plate 10 suitable for transporting goods, especially stacked bagged goods, especially with several 25 kg bags per tier. The conveying plate 10 is substantially rectangular and the dimensions of the conveying plate 10 substantially correspond to common conveying pallet dimensions. The base body of the conveyor plate 10 itself is flat and has a thickness of only a few millimeters (for example about 2.5 mm to 5 mm), and said base body comprises four arches 12, two of which are parallel to each other and spaced apart from each other. They extend in the longitudinal direction of the conveyor plate 10 and the two arches 12 likewise extend parallel to and spaced apart from one another in the transverse direction of the plate 10 . From figure 1 As can be seen in , the four arches 12 are thus grid-shaped and formed cutting into each other. For strengthening purposes, the panel 10 further includes a peripheral border 14 extending upwardly at abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com