Mowing device for lawn mower and mounting method for mowing device

A technology of cutting device and installation method, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., which can solve the problems of high energy consumption, uneven length of cut grass, and high manufacturing cost, so as to reduce energy consumption and wind resistance , the effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

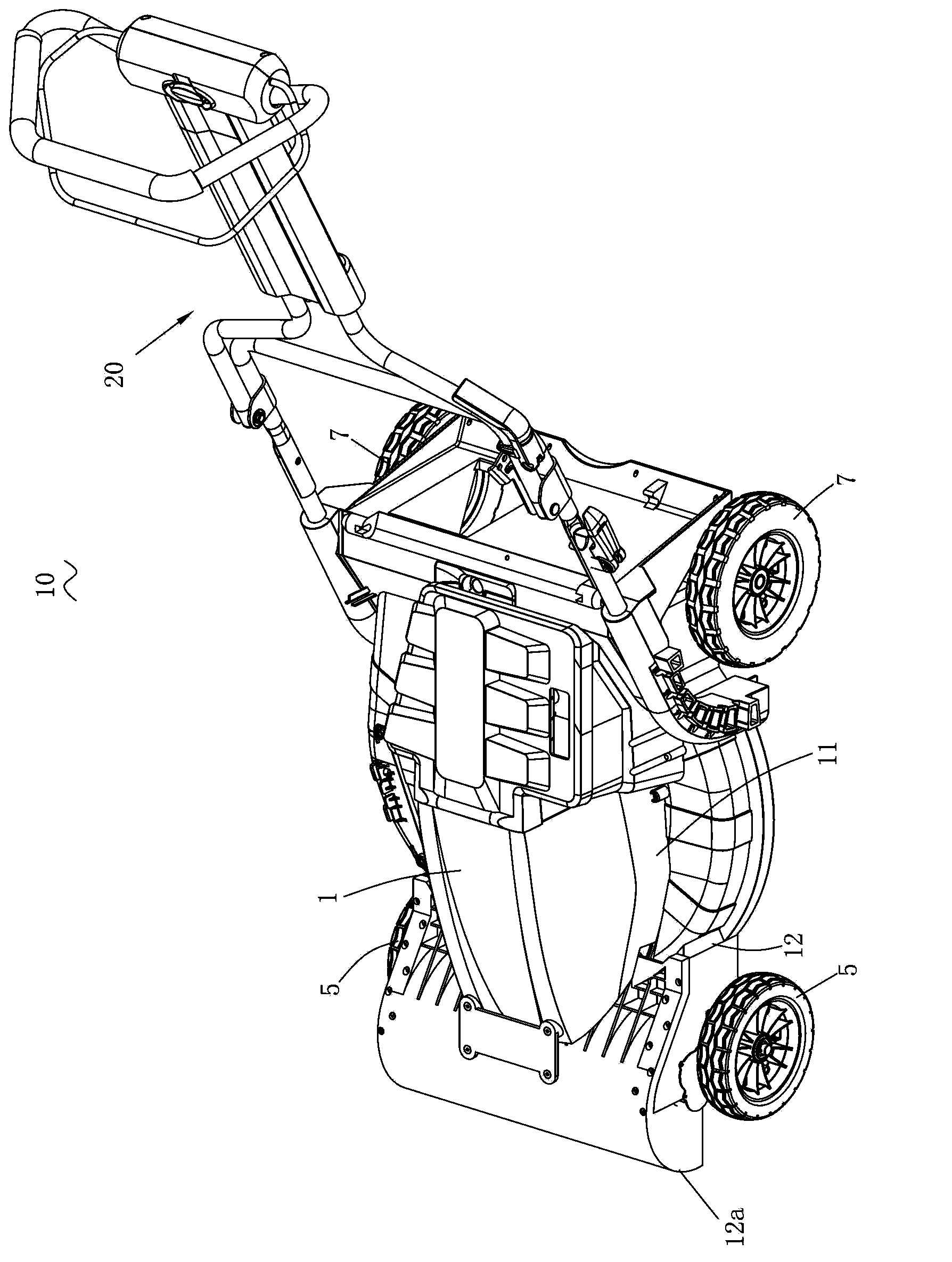

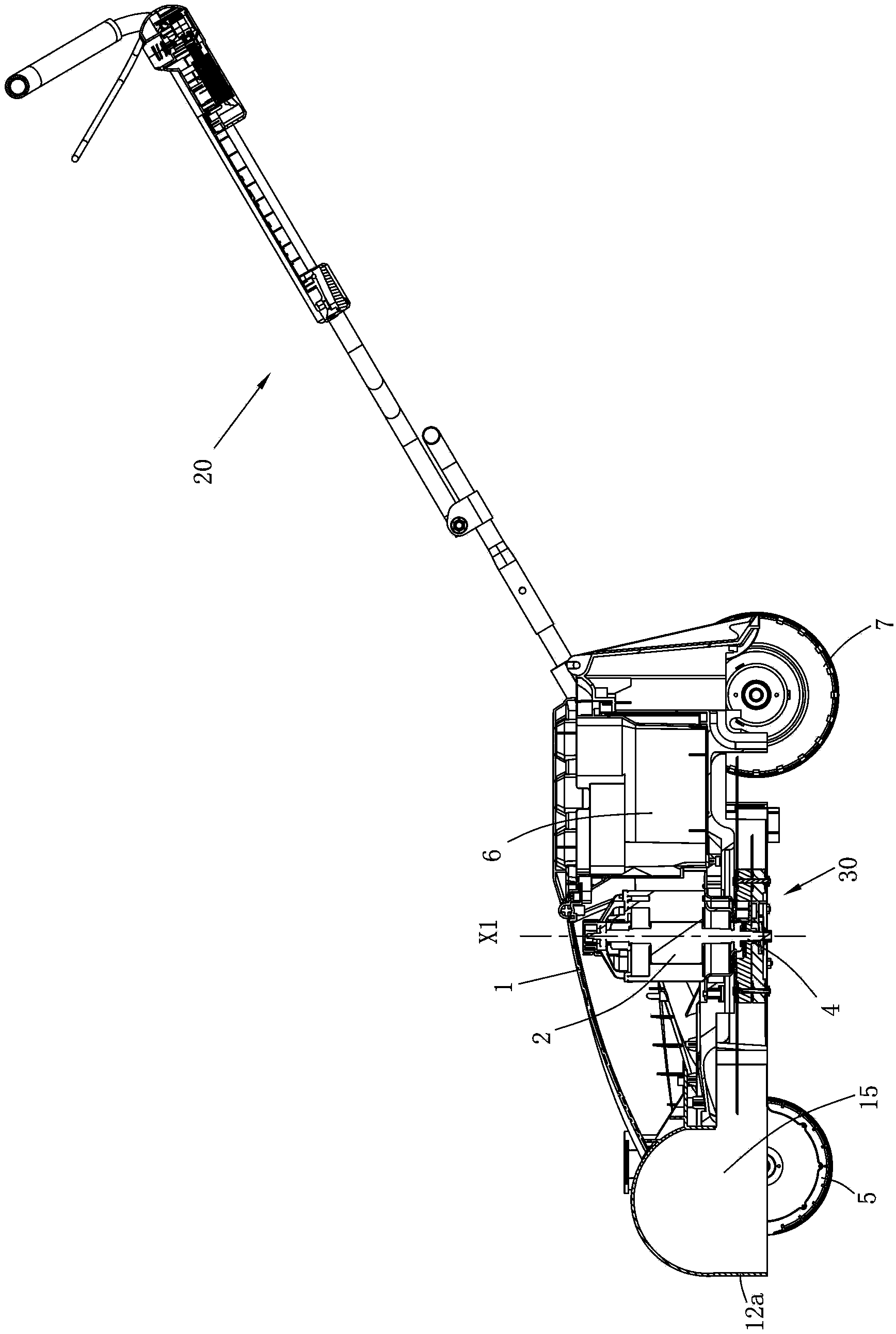

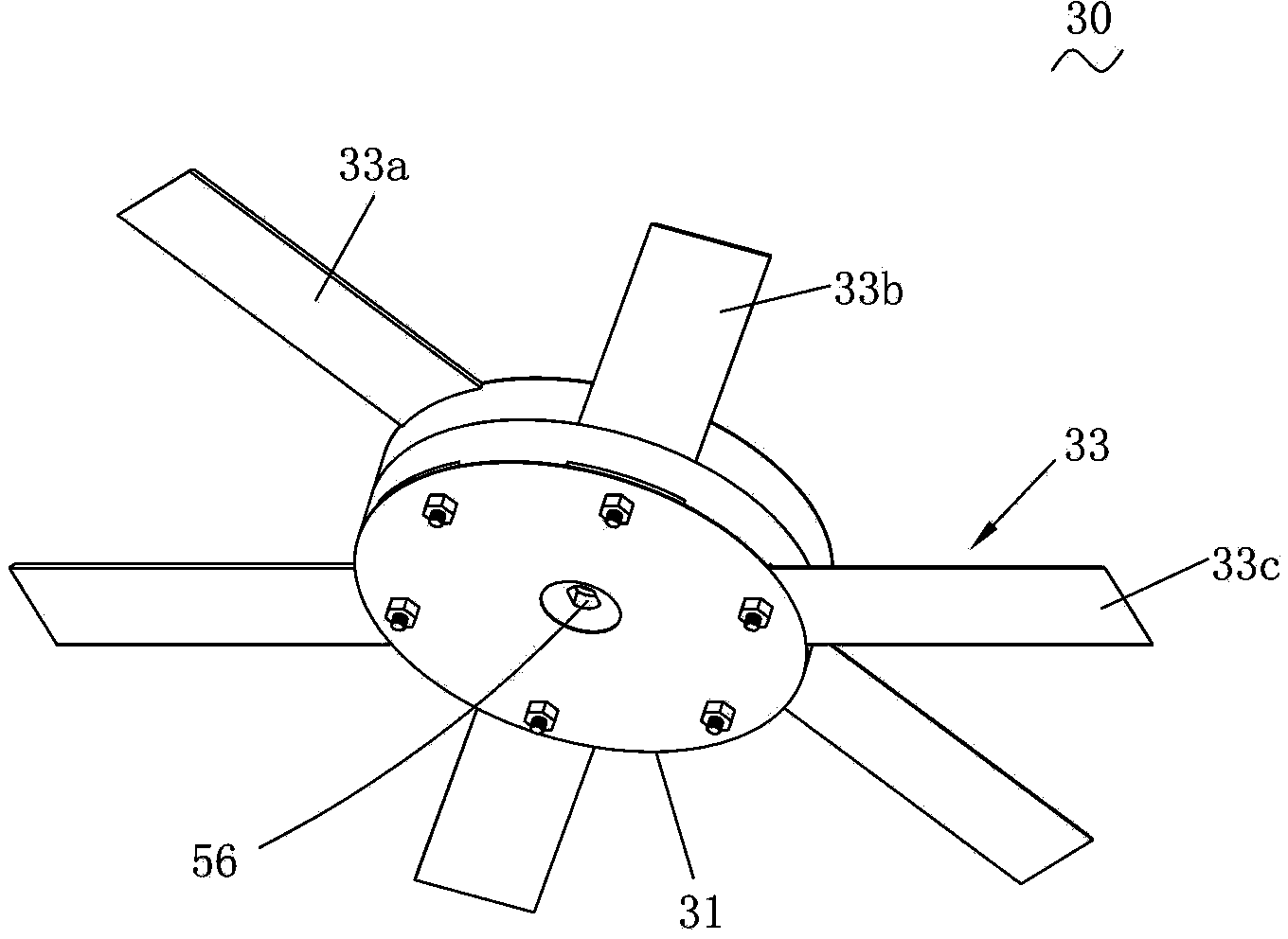

[0047] refer to figure 1 , figure 2 As shown, the power lawn mower 10 of the first embodiment of the present invention has a casing 1, and a plurality of rollers are arranged at the bottom of the casing 1 for supporting the lawnmower to move on the ground. The rollers include a pair of front wheels 5 supporting the front casing and a pair of rear wheels 7 supporting the rear casing. An operating mechanism 20 extending to the rear of the lawn mower 10 is connected to the rear casing for controlling the operation of the lawn mower 10 . The casing 1 includes a top wall 11 and a surrounding wall 12 extending from the top 11 to the ground. The top 11 and the surrounding wall 12 form a cutting cavity 15 . When the mower 10 advances in the cutting direction, grass enters the cutting cavity 15 from the bottom of the front end portion 12a of the surrounding wall. The casing 1 is provided with a driving device. The driving device in this embodiment is a motor 2. The output shaft 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com