Process air temperature control system and method of air flow drying machine

A technology of temperature controller and temperature control loop, which is applied in the direction of using electric means for temperature control, auxiliary controller with auxiliary heating device, tobacco preparation, etc. Control the temperature setting value and other issues to achieve the effect of product quality assurance and follow-up improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

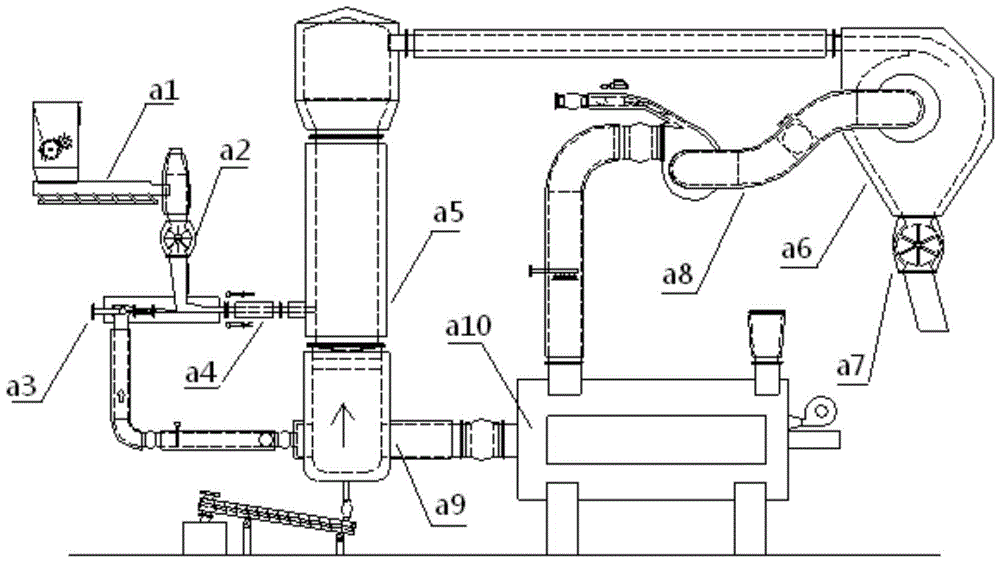

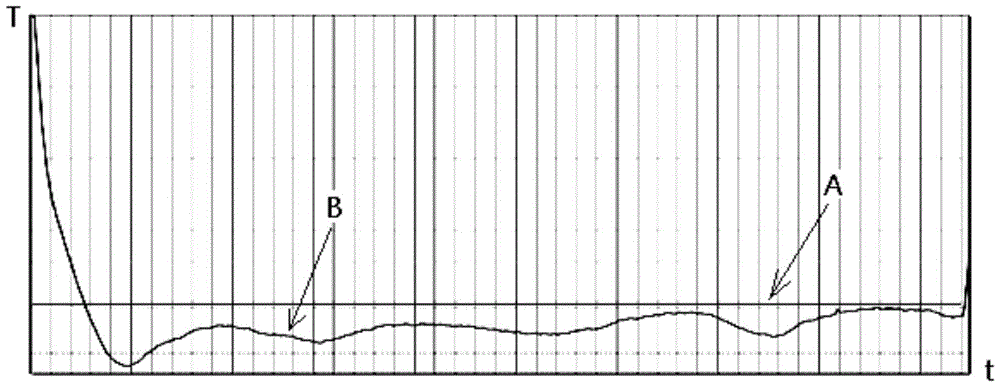

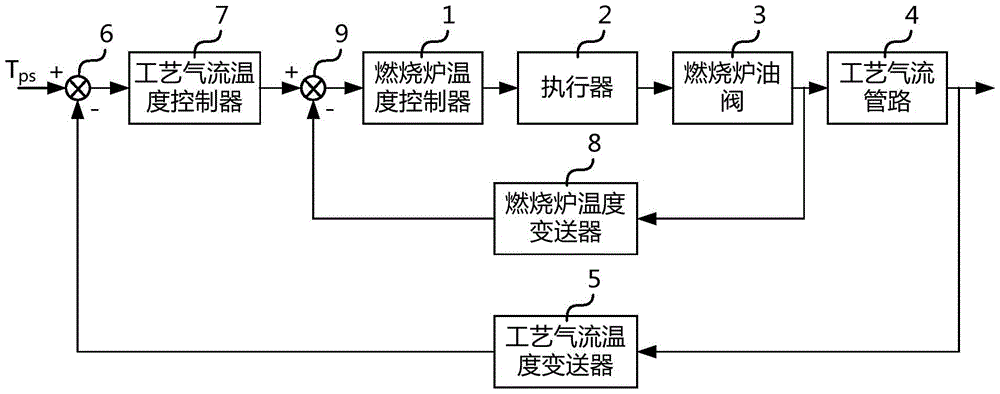

[0034] As mentioned above, the inventor found that the system control points of the existing airflow drying machine do not match the process control points, which makes it difficult for the temperature of the combustion furnace to meet the process requirements. Based on this finding, the present invention focuses on optimizing the control process to achieve accurate control of the temperature of the process airflow (the temperature of the airflow directly in contact with shredded tobacco). Such as image 3 As shown, it is a structural schematic diagram of an embodiment of the air flow temperature control system of the air flow drying machine process of the present invention. In this embodiment, the process air temperature control system of the air-flow silk drying machine includes a combustion furnace temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com