Solid-liquid separator with function of automatically separating and cleaning sundries in faeces

A solid-liquid separator and automatic separation technology, applied in the fields of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of unclean separation of organic matter and sundries, pollution of the environment without cleaning function, and difficulty in maintenance. Easy, low equipment cost, simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

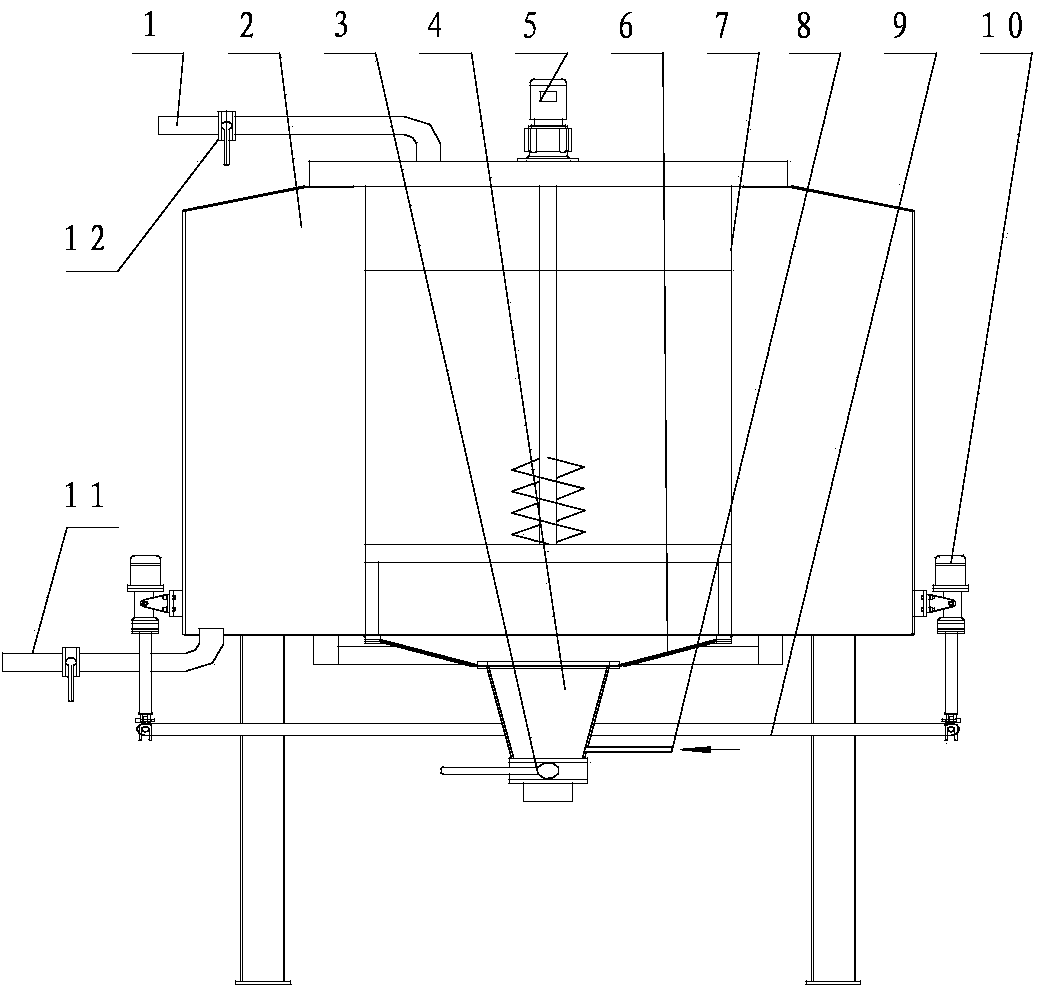

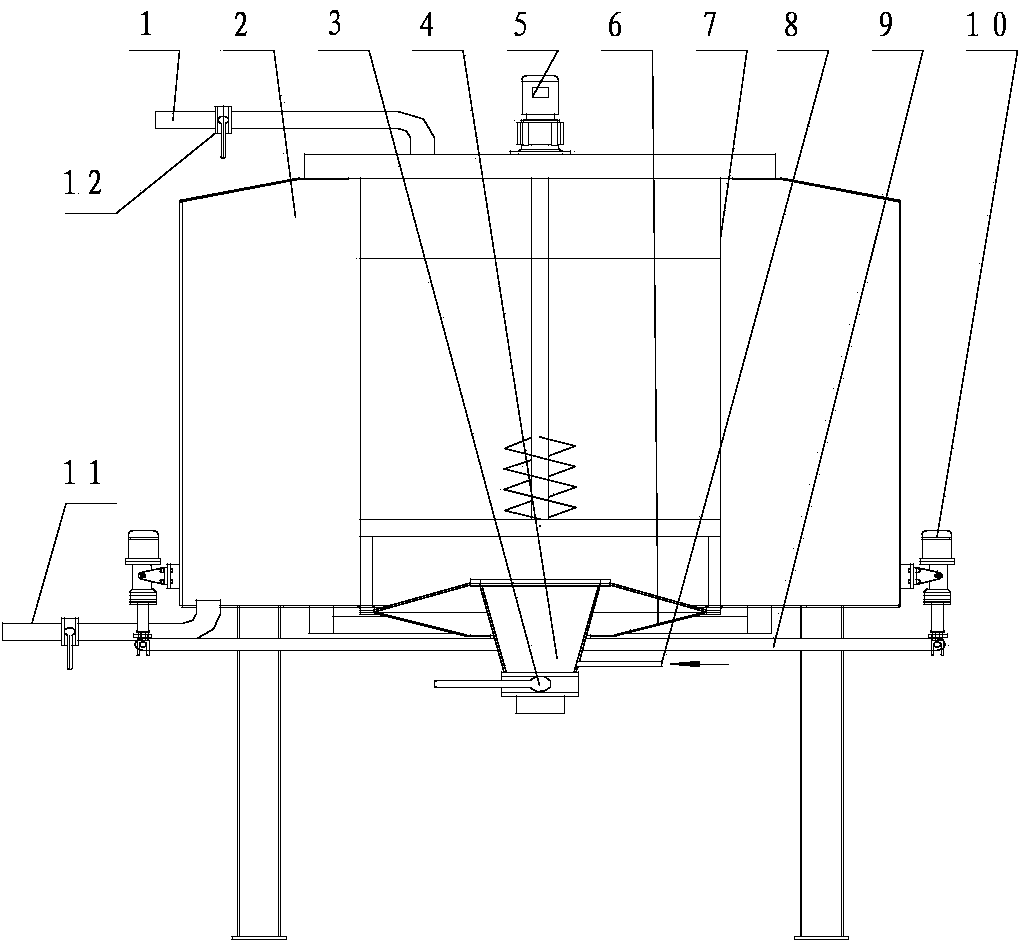

[0014] The cylindrical tank body 2 is made of stainless steel plate. There is a cylindrical stainless steel wire mesh 7 inside the tank body 2. The upper end of the cylindrical stainless steel wire mesh 7 is connected with the upper cover of the tank body 2. The cylindrical steel wire mesh The lower end of 7 is connected around the circular through hole at the bottom of the tank body 2, the center of the loam cake at the top of the tank body 2 is equipped with a stirring system 5, and a manure liquid inlet pipe 1 is fixedly installed on one side of the loam cake, and the manure liquid inlet The inlet valve 12 is used to open and close. There is a circular through hole in the center of the bottom plate of the tank body 2. The lower part of the through hole is a cone-shaped sundry storage tank 4. The lower part of the sundry storage tank 4 is placed on the bracket 9, and its bottom A discharge valve 3 is fixedly installed, and a water inlet pipe 8 is fixedly installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com