Metal surface derusting device

A metal surface and derusting wheel technology, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of automatic tracking and derusting, and the reduction of manual labor intensity, so as to achieve the reduction of manual labor intensity and self-locking Strong, high processing precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

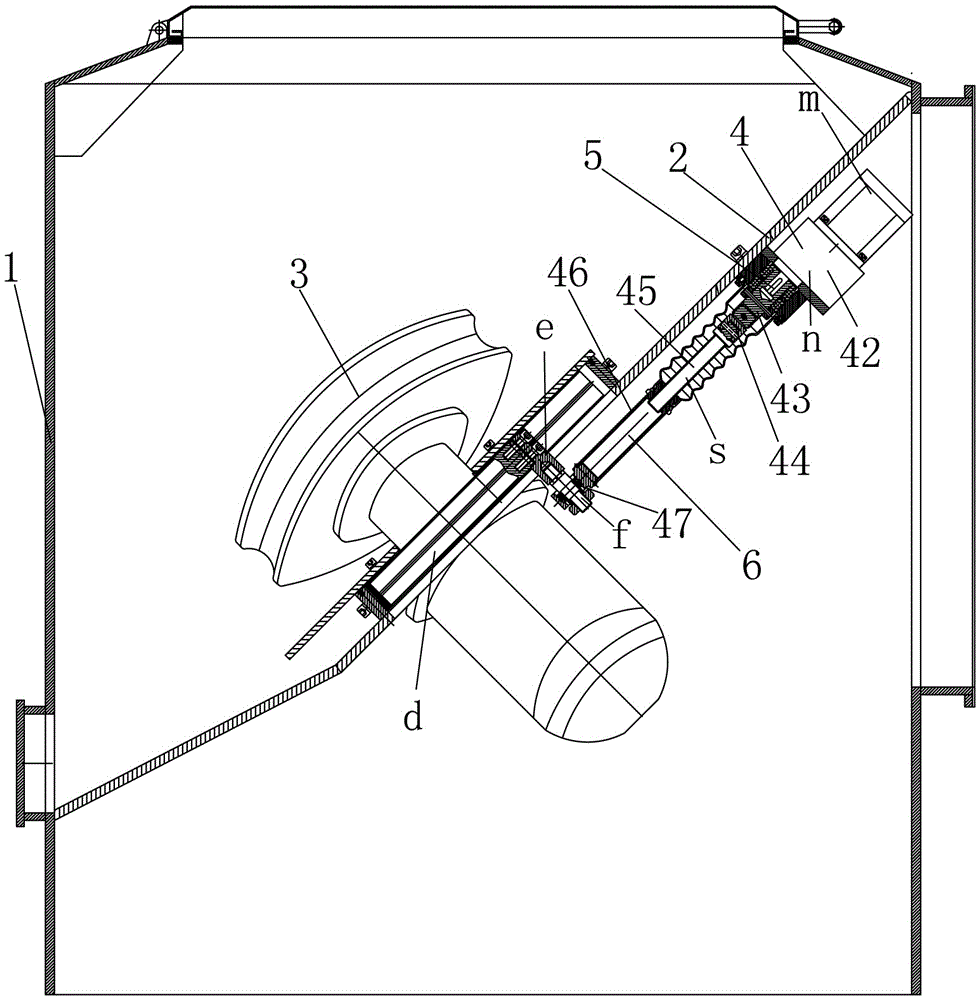

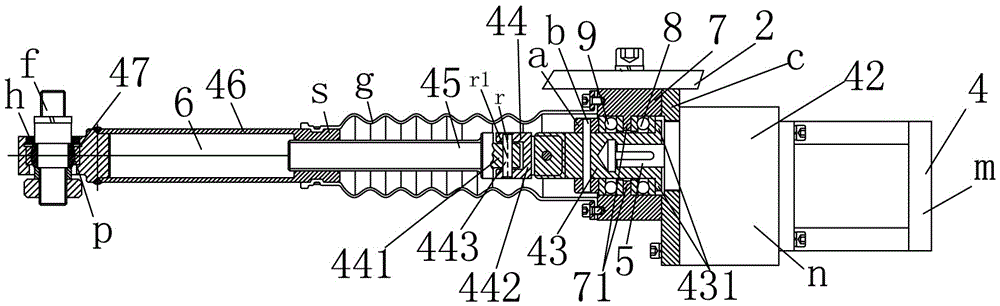

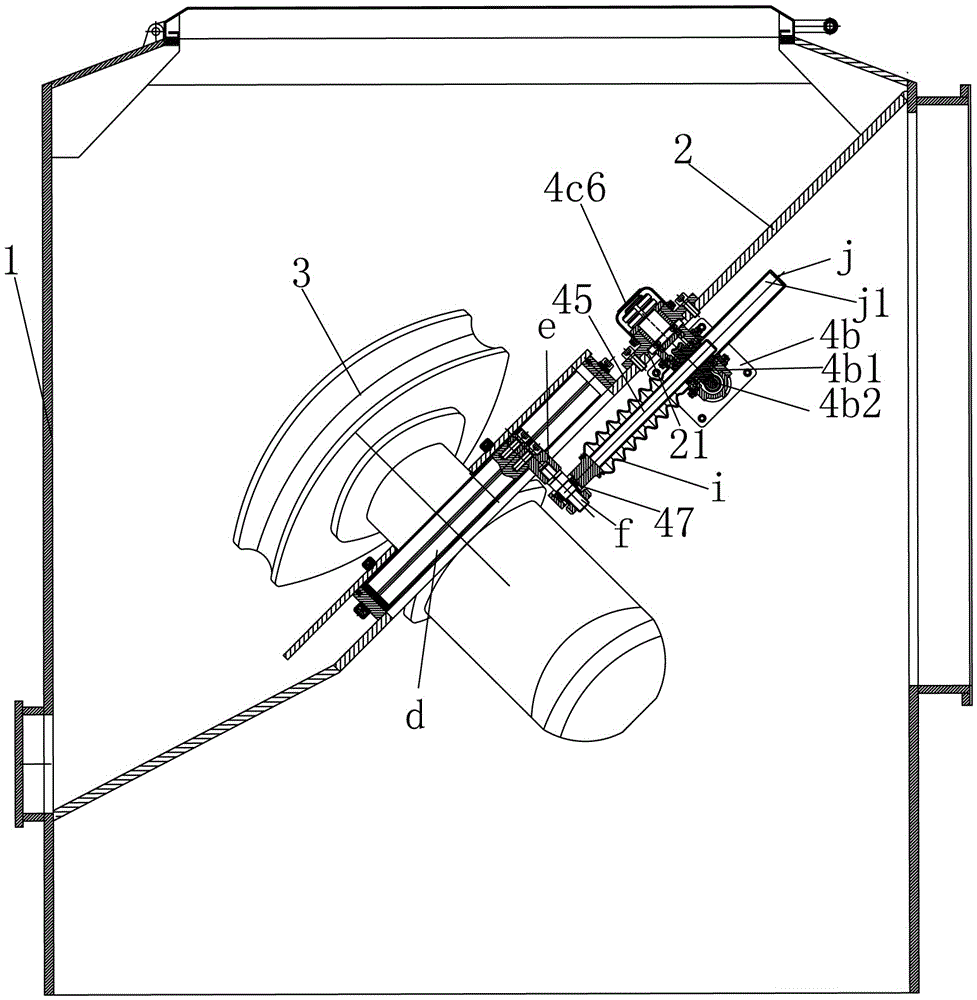

[0012] Such as figure 1 , figure 2 As shown, the first embodiment of the metal surface derusting device provided by the present invention includes a box body 1, an inner sloping plate 2 and a derusting wheel 3 are arranged in the box body 1, and the derusting wheel 3 can be linearly and movably installed Inner inclined plate 2, described inner inclined plate 2 is provided with descaling wheel feeding device 4, and described descaling wheel feeding device 4 comprises motor part m, deceleration part n and feeding part s, here motor part m According to actual needs, AC and DC asynchronous motors, synchronous permanent magnet motors, speed-adjusting motors, stepper motors, and servo motors can be used, and the motor part m, deceleration part n, feed part s and derusting wheel 3 are sequentially driven, that is, That is to say, the motor part m drives the deceleration part n to move, the deceleration part n drives the feed part s to move, the feed part s drives the derusting whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com