Overflow device of acetylene sludge slurry head tank

An overflow device and calcium carbide slurry technology, applied in the field of chemical production, can solve problems such as pipeline blockage, slow flow rate of slurry, easy sedimentation and fouling, etc., and achieve the effect of easy cleaning and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

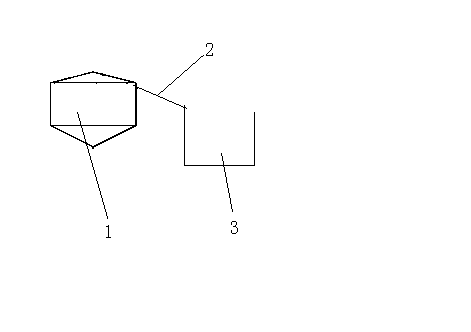

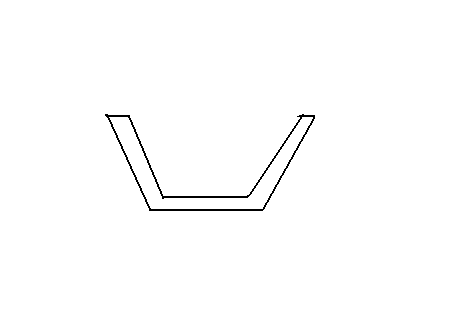

[0011] Such as figure 1 Or as shown in 2, the present invention includes a slurry header tank 1, the overflow port of the slurry header tank 1 is connected to the overflow tank 2 opened above, and the other end of the overflow tank 2 is connected to the collection tank 3, and the overflow The cross section of the groove 2 is U-shaped or inverted trapezoidal.

[0012] The overflow tank is inclined from top to bottom from the slurry head tank 1 to the collection tank 3 .

[0013] During production and use, due to large fluctuations in the liquid level of the slurry header tank 1, in order to prevent the slurry pump in the slurry header tank from not being evacuated, try to ensure a small overflow of the header tank to achieve liquid level control. In addition, the overflow tank should be strengthened. The cleaning of the overflow makes the overflow smooth and the liquid level stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com