High-performance daylighting roof

A high-performance technology for daylighting roofs, applied in roofs, buildings, building structures, etc., can solve the problem of poor watertightness, airtightness, heat preservation and sound insulation of daylighting roofs, failure to meet ventilation and fire protection requirements, and ventilation effects of daylighting roofs It can achieve the effect of increasing ventilation and fire-fighting and smoke exhaust functions, simple daily maintenance, easy deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

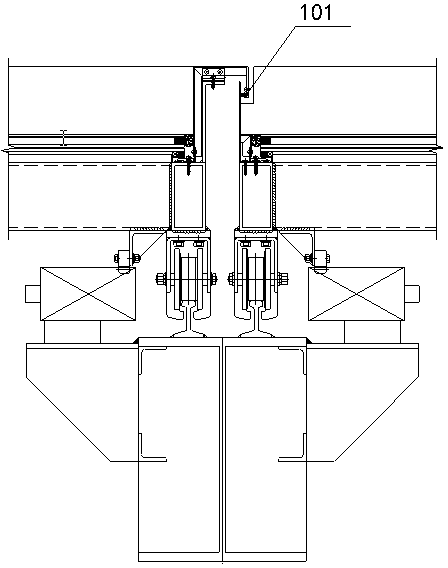

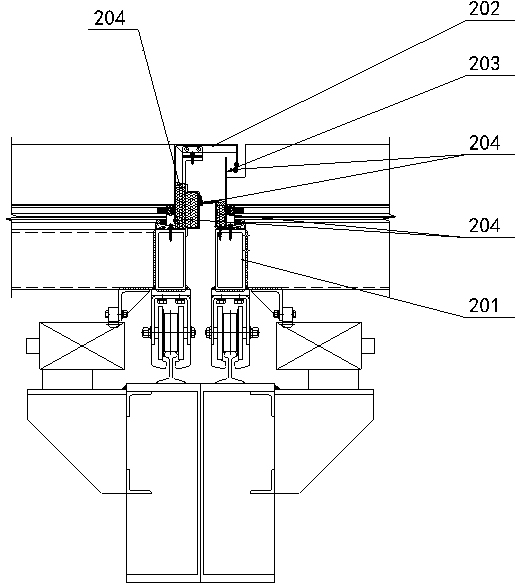

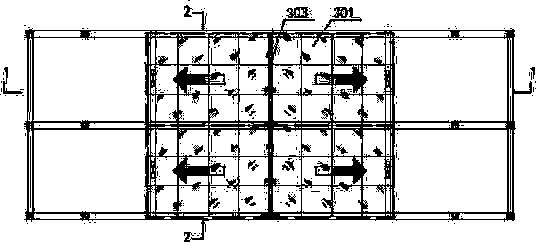

[0020] A high-performance daylighting roof, such as figure 2 - As shown in Figure 3, it includes a movable sunroof 301, a lateral partition 302, a ridge top plate 303, a power device 304, a transmission device 305, a sealing device 306 and a control device, the power device 304 includes a motor and a reducer, and the transmission device 305 includes a gear , rack and cardan linkage. The sealing device 306 includes a metal keel 201, a cold-formed aluminum plate 202, and an aluminum alloy profile 203. The sealing device 306 is sealed with a double-channel low-friction rubber strip 204, such as EPDM rubber whose surface is sprayed or flocked. The cavity of the cold-formed aluminum plate 202 is filled with polyurethane foam material. When forming, the cold-formed aluminum plate is first formed into a plate with a cavity. After the polyurethane foam material is injected, the sealing is treated with weather-resistant sealant.

[0021] Such as Figure 4 As shown, the lateral parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com