An aluminum alloy building formwork

A construction formwork and aluminum alloy technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of many solder joints, welding deformation, complex structure, etc., and achieve high turnover times, fast and accurate processing, and connection firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

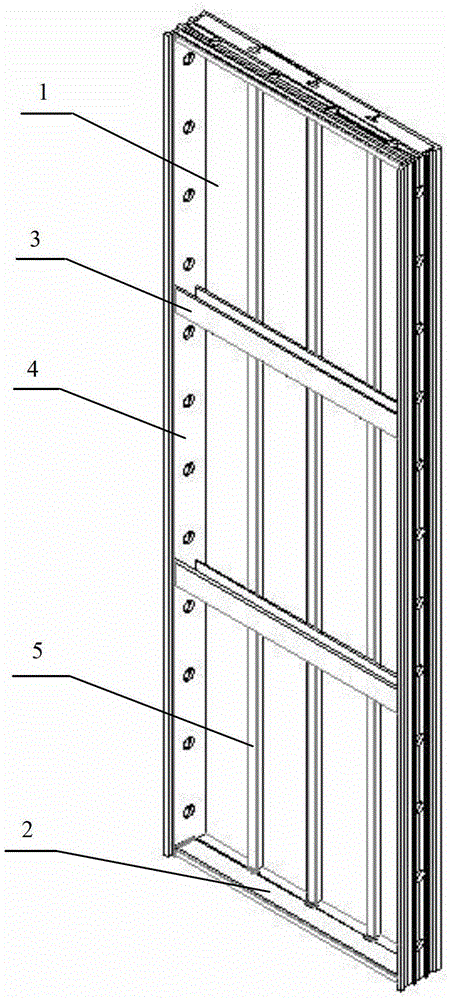

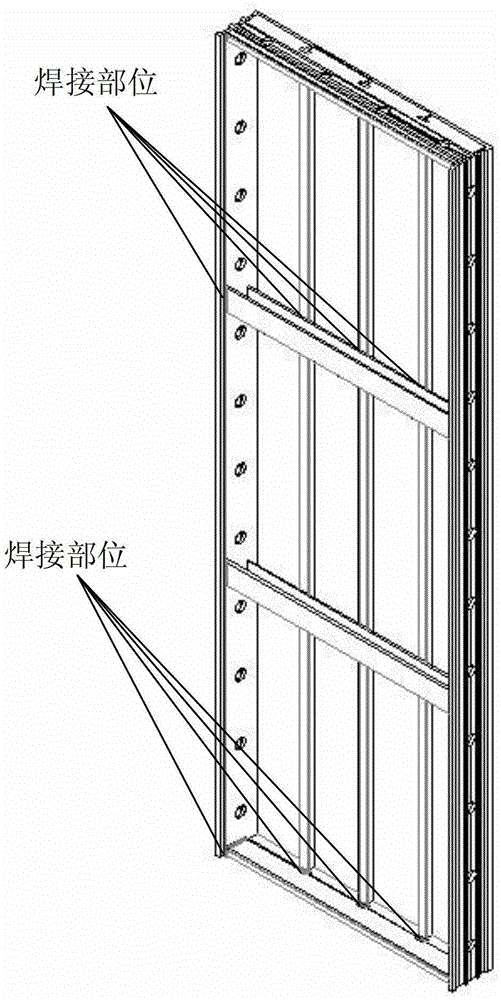

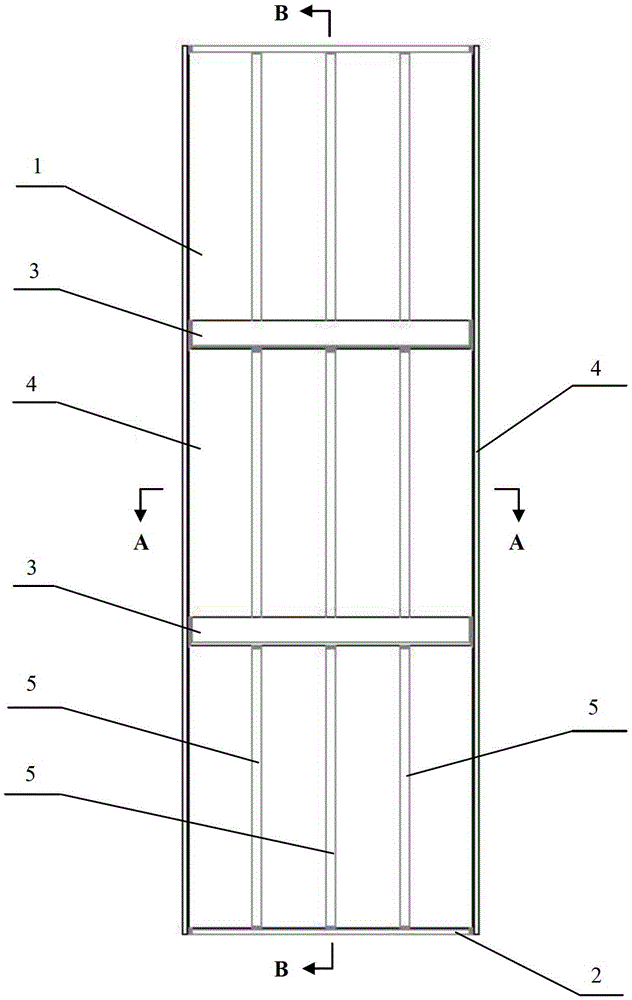

[0031] Such as figure 1 As shown, the aluminum alloy building formwork of the present invention comprises panel 1, end plate 2, transverse rib 3; image 3 As shown, the two sides of the panel 1 are provided with side plates 4 equal in length to the panel 1, and the bottom of the panel 1 is provided with longitudinal ribs 5 equal in length to the panel 1, the longitudinal ribs 5 are parallel to the side plates 4, and the transverse ribs 3 are parallel to the Plate 2 is parallel. The panel 1 is integrally extruded with the side plate 4 and the longitudinal rib 5, from Figure 8 , Figure 9 It can be seen that this makes the structure simple, reduces welding, and the welding position is reasonable, and the surface of the panel is smooth and flat without deformation.

[0032] The perspective view of end plate 2 is as follows Figure 11 As shown, the end plate 2 is an integrated profile, and the end plate 2 is provided with a notch 7. The shape of the notch 7 is the same as tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com