Clutch actuated by inertia mass and friction damping

A technology of frictional damping and inertial mass, which is applied in the field of damping and can solve problems such as the inapplicability of one-way transmission devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

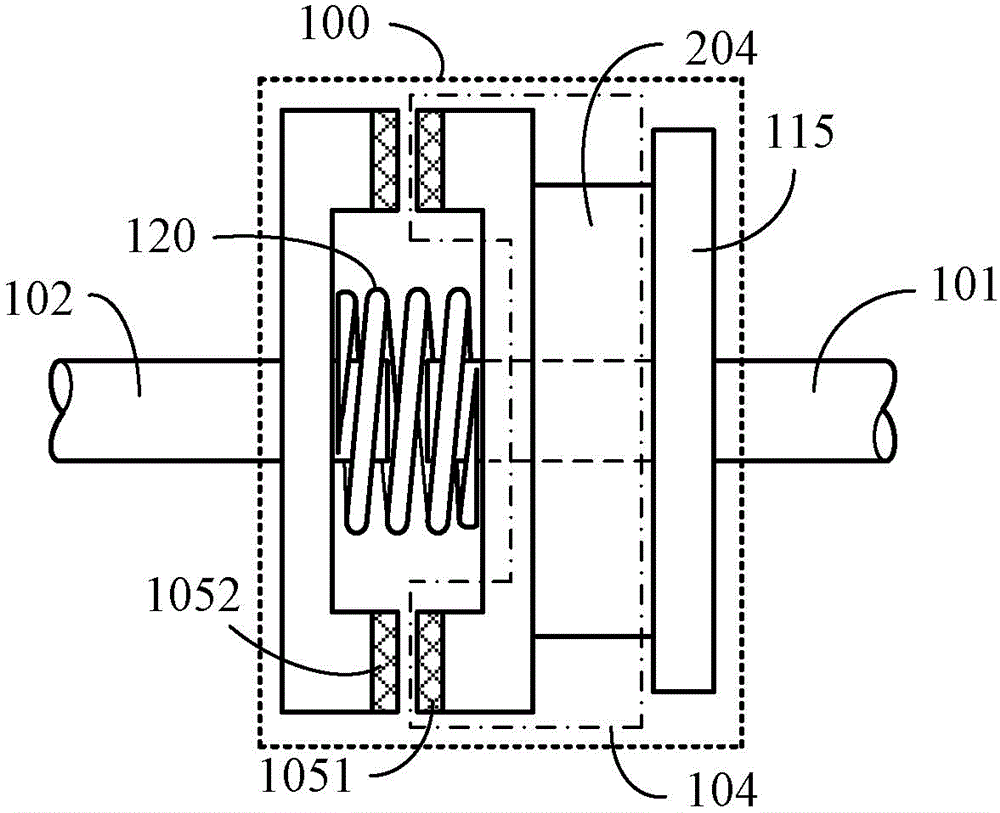

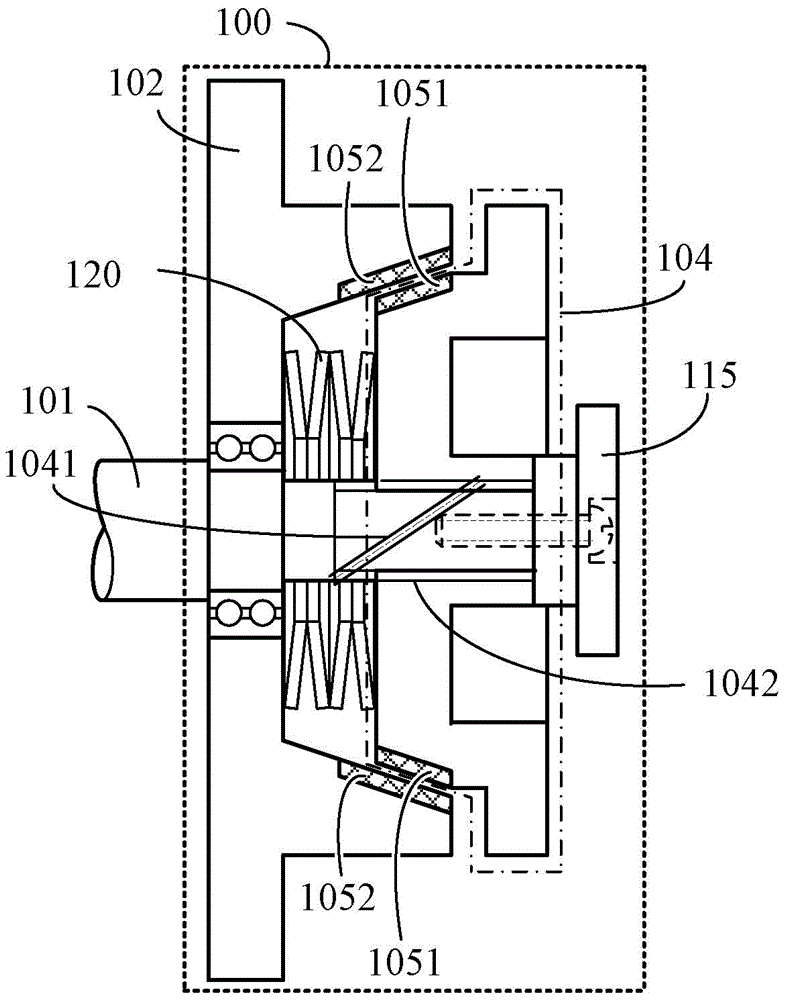

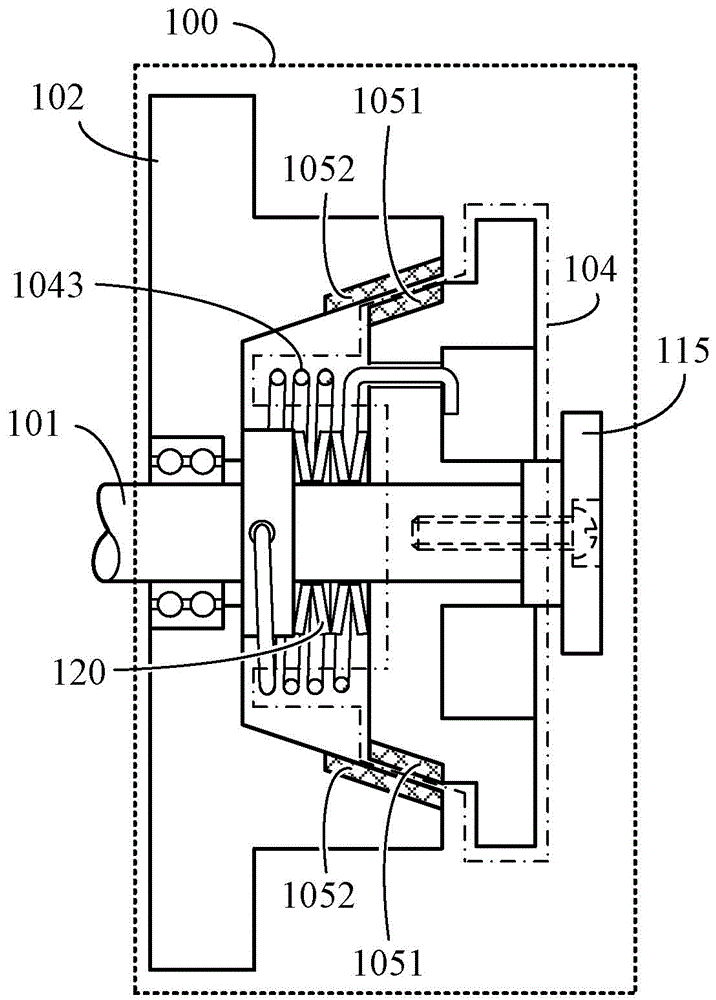

[0147] The clutch actuated by inertial mass and frictional damping in the present invention is a relay transmission structure assembly 104 with no additional damping device. The inertial mass of the relay transmission structure assembly 104 itself and the frictional damping effect between the adjacent sliding contact parts make relative displacements to drive the relay transmission structure assembly 104 and the relay output clutch structure provided for and arranged on The output side clutch structure 1052 of the output side 102 is closed to transmit the rotational energy, and presses the return actuating spring 120 disposed between the relay output clutch structure and the output side clutch structure 1052 .

[0148] When the slewing drive torque on the prime mover side 101 disappears, the relay transmission structure assembly 104 and the set relay output clutch structure are reset by the action of the return actuation spring 120, so that the relay output clutch structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com