An automatic feeding device for aluminum ingots

An automatic feeding device and technology of aluminum ingots, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as uncontrollable temperature of molten aluminum, explosion of molten aluminum, hidden safety hazards, etc., to prevent molten aluminum from splashing and prolong use. Longevity, Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

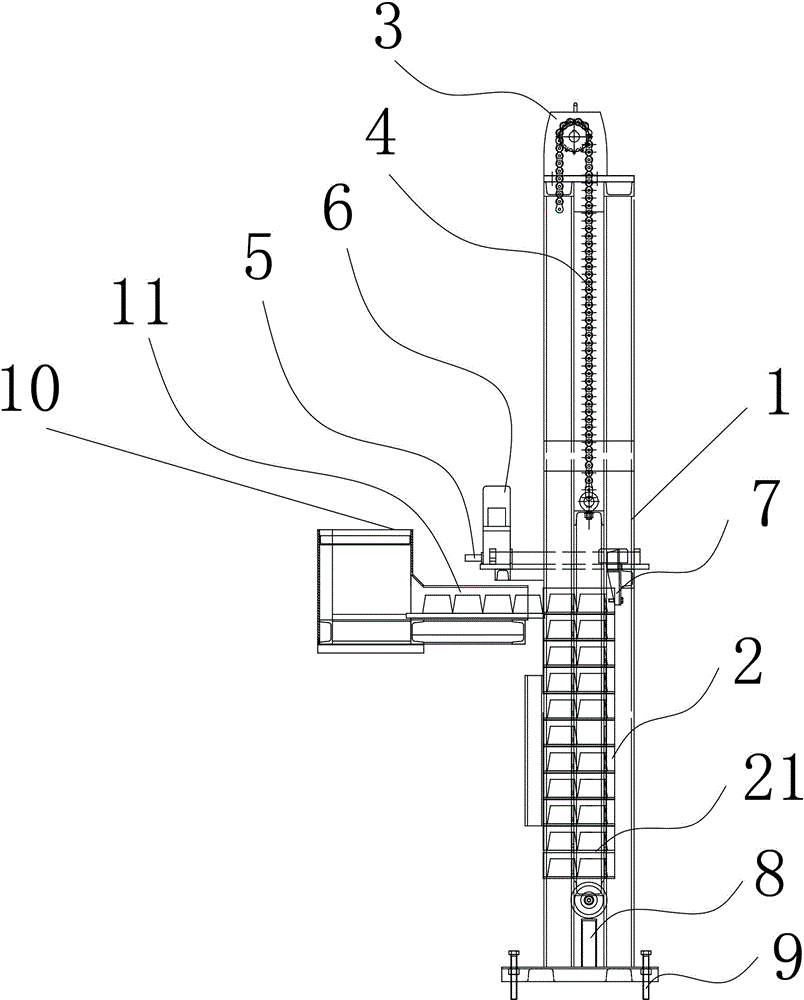

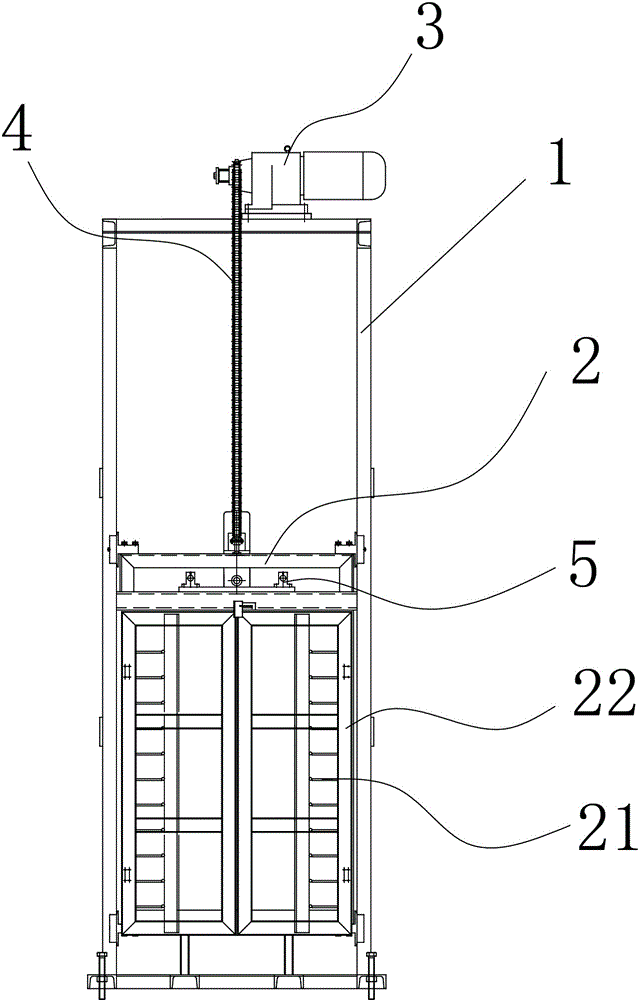

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 and figure 2 , an automatic feeding device for aluminum ingots, comprising a feeder frame 1 and an aluminum ingot lifting frame 2, the upper end of the feeder frame 1 is provided with a basket lifting motor 3, and the basket lifting motor 3 passes through a basket lifting chain 4 is connected with the aluminum ingot lifting material frame 2, one end of the material basket lifting chain 4 is connected to the aluminum ingot lifting material frame 2, and the other end is wound on the material basket lifting motor 3, driven by the material basket lifting motor 3 to lift the aluminum ingot Box 2 goes up or down.

[0014] The aluminum ingot lifting material frame 2 is provided with an aluminum ingot placing bracket 21, and the aluminum ingot lifting material frame 2 is divided into eleven layers, and each layer has two aluminum ingot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com