Two-dimensional adjusting mechanism of matrix type reflecting mirror group

A mirror group and two-dimensional adjustment technology, applied in installation, optics, instruments, etc., can solve the problems of inability to move the mirror, unreasonable design, and low adjustment accuracy, and achieve easy promotion and use, simple structure, and high reflection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

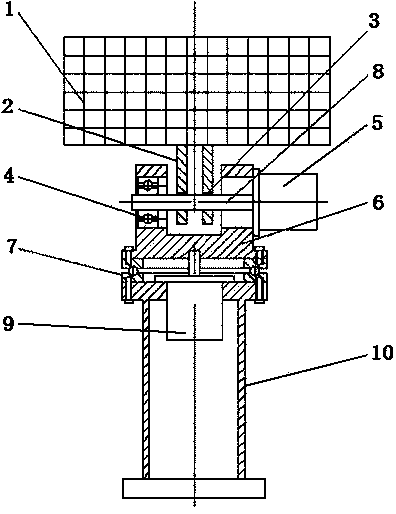

[0019] Such as figure 1 The shown two-dimensional adjustment mechanism of a matrix mirror group includes a bracket 2 for installing and supporting the matrix mirror group 1, a stepping motor-5 for driving the bracket 2 to rotate along a horizontal axis, and a The stepper motor 9 that drives the mounting base 6 to rotate along the vertical axis and the base 10 for installing and supporting the stepper motor 9, the upper end surface of the base 10 is fixedly equipped with a rotary support 7 and a stepper motor 9 , the upper side of the slewing support 7 is equipped with a mounting seat 6, the power output shaft of the stepping motor 2 passes through the slewing support 7 and is connected to the bottom of the mounting seat 6, and the upper side of the mounting seat 6 is equipped with a stepping motor -5, the power output shaft of the stepper motor -5 is connected to one end of the transmission shaft 8 through a coupling, the middle part of the transmission shaft 8 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com