Power distribution cabinet heat-dissipation system

A heat dissipation system and power distribution cabinet technology, which is applied in the cooling/ventilation of substations/switchgears, etc., can solve the problems of high total resistance value, difficult discharge of power distribution cabinets, and limited heat dissipation effect, so as to achieve high heat dissipation efficiency and environmental protection High benefit, lower temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be described in more detail below with reference to the drawings and embodiments.

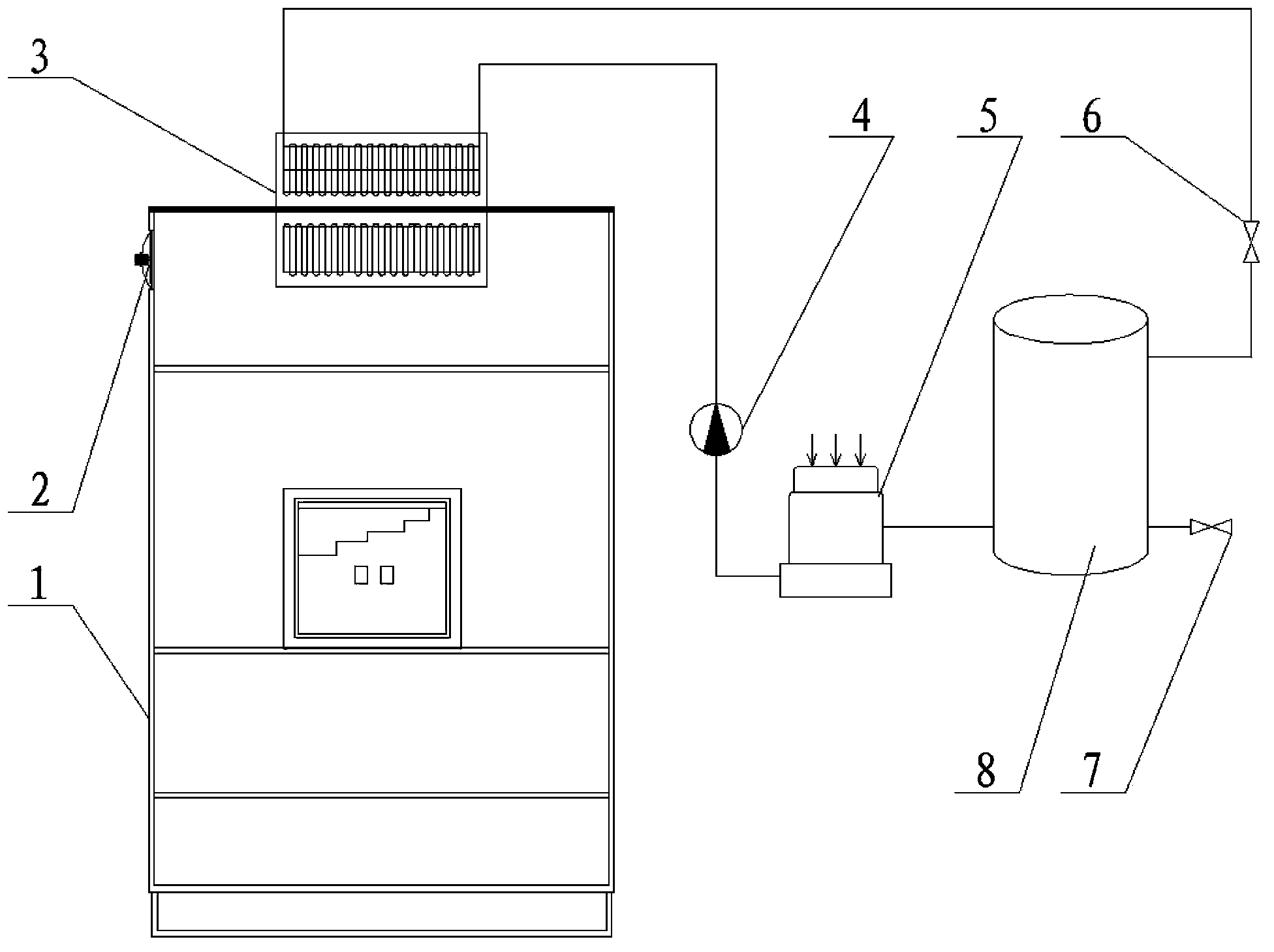

[0014] As shown in the figure, the heat dissipation system of the power distribution cabinet of the present invention includes a cabinet body 1. The cabinet body 1 has a hollow rectangular parallelepiped structure as a whole. A circulating fan 2 for circulating air inside the cabinet body is installed above the side plate of the cabinet body 1; A water cooling system is also installed on the top of the cabinet 1, specifically including a heat exchanger 3 installed on the top of the cabinet 1 to transfer the heat inside the cabinet to the outside of the cabinet. The cooling section of the heat exchanger 3 is provided with cold water coils and cold water pans. The pipe is connected to the water return valve 6, the water tank 8, the cooling tower 5, and the circulating water pump 4 in sequence through the pipeline, and finally connected back to the cold water coil of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com