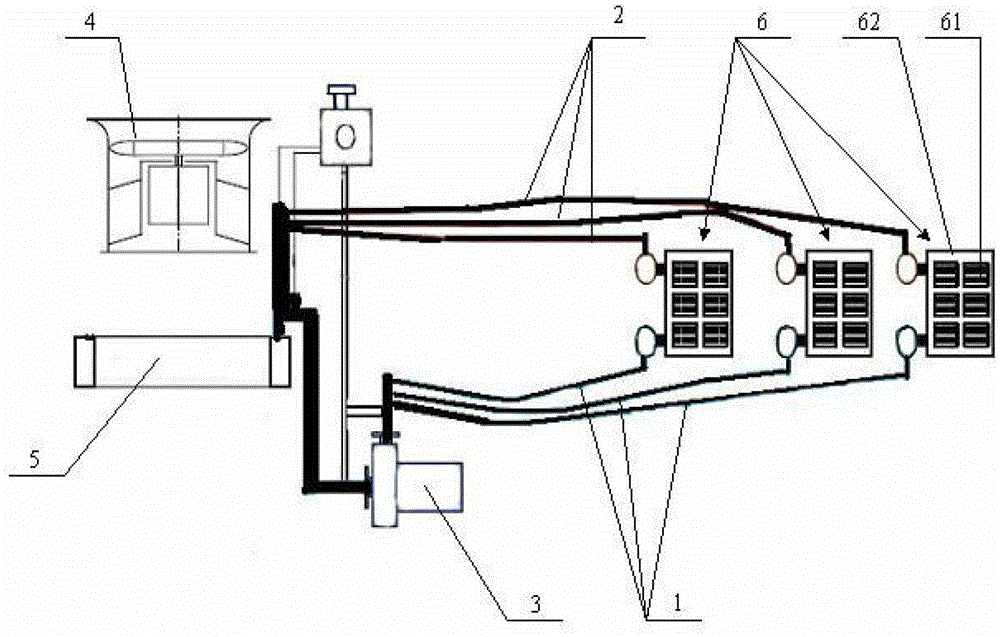

Converter cooling lines and cooling units

A technology for cooling pipelines and converters, which is applied in the direction of output power conversion devices, cooling/ventilation/heating transformation, electrical components, etc. Uniformity and other issues to achieve the effect of improving heat dissipation balance and cooling effect, flow balance, and reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

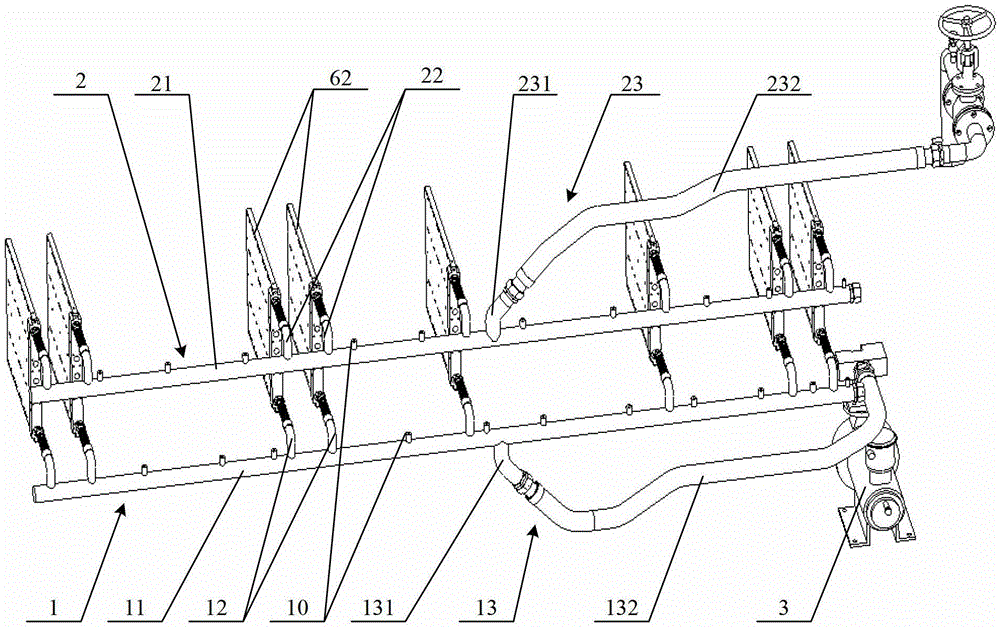

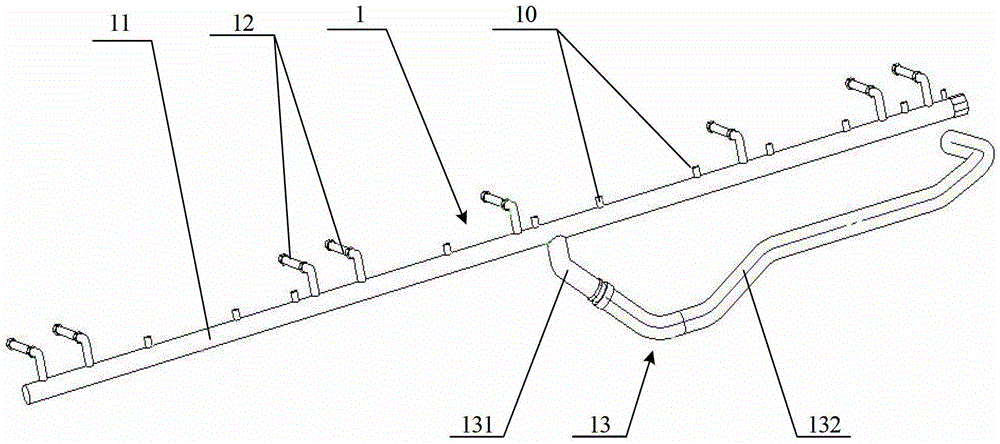

[0032] refer to Figure 2~4 , figure 2 A schematic diagram of the converter cooling pipeline provided by the embodiment of the present invention; image 3 for figure 2 The schematic diagram of the water inlet pipeline in ; Figure 4 for figure 2 Schematic diagram of the outlet pipeline in .

[0033] Such as Figure 2~4 As shown, the converter cooling pipeline provided in this embodiment includes a water inlet pipeline 1 and a water outlet pipeline 2 .

[0034] The water inlet pipeline 1 includes a water inlet main pipe 11 and a plurality of water inlet pipes 12; the water inlet main pipe 11 is used to communicate with the water outlet of the water pump 3; The other end of 12 is used to communicate with the water inlet of the water-cooled substrate 62 of the power module.

[0035] The water outlet pipeline 2 includes a water outlet main pipe 21 and a plurality of water outlet pipes 22; the water outlet main pipe 21 is used to communicate with the water inlet of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com