Wafer level applied RF shields

A wafer-level, wafer-based technology, applied in the fields of magnetic/electric field shielding, semiconductor/solid-state device components, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a low cost method for wafer level application of RF shielding used in multiple electronic packaging formats and applications. The method is particularly useful in embedded die packaging applications to provide high throughput RF shielding for wafer level applications.

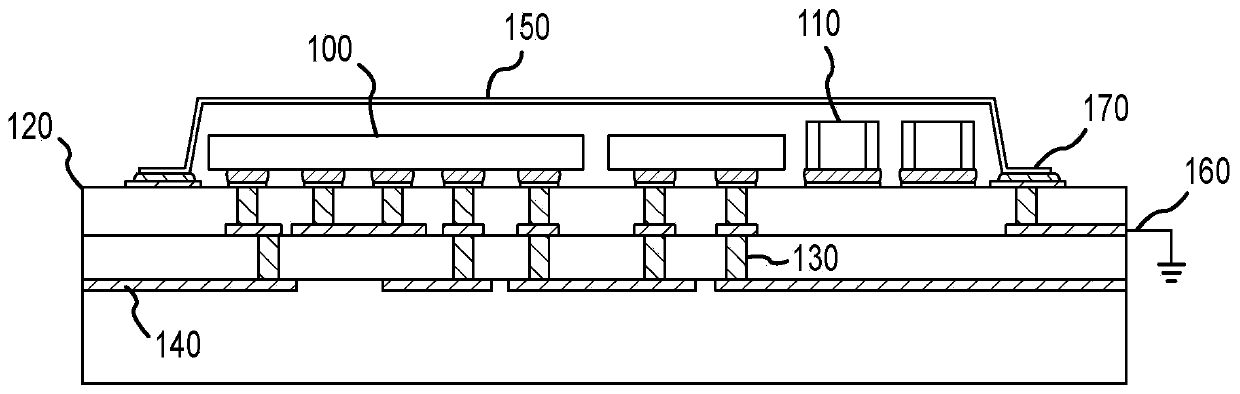

[0022] figure 1 A typical EMI shielding system on a printed wiring board (PWB) is shown. Single or multiple active and / or passive components 100 together with surface mounted discrete components 110 may be used to form an electronic system. The components are mounted on a typical printed circuit or wiring board 120 . Electrical connections between components are made through vias 130 and redistribution traces 140 using a standard PWB. A typical SMT board mount RF shield 150 covers the system components and is connected to electrical ground 160 through the PWB circuit. The RF shield is typically welded or glued to the PWB around the perimeter of component 170 .

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com