The method of increasing the qualified rate of water content of the shredded stems by controlling the amount of water added to the moistening machine

A technology for moistening the stems and adding water, which is applied in the field of tobacco processing, and can solve the problems that affect the moisture content of the cut stems, the processing quality of the dried stems, the water loss of the tobacco stems, and the low moisture content of the cut stems. Guarantee the quality of combustion and absorption and physical and chemical properties, increase production capacity, and achieve the effect of efficient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

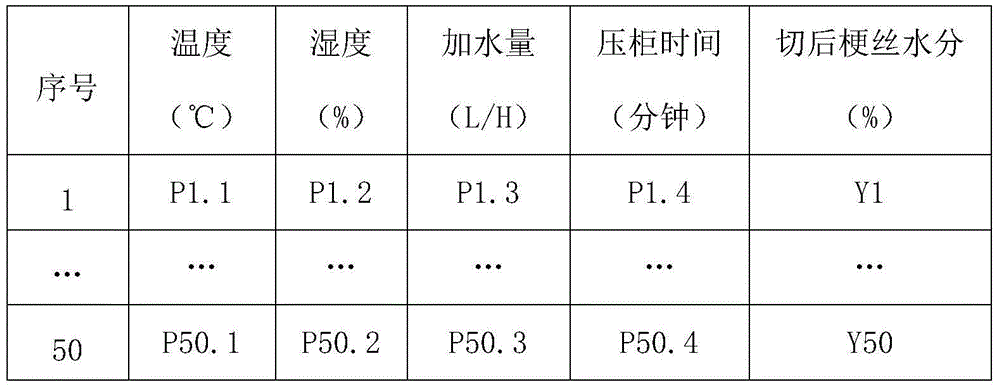

[0019] The method for controlling the amount of water added to the stem moistening machine according to the embodiments of the present invention will be described in further detail below in conjunction with specific examples, but it is not intended to limit the present invention.

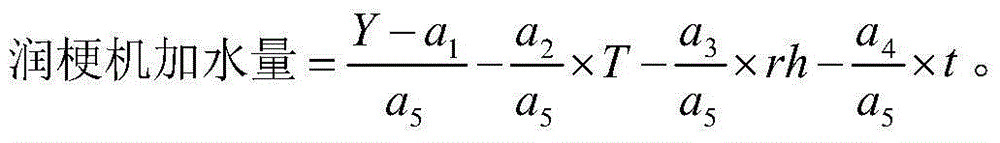

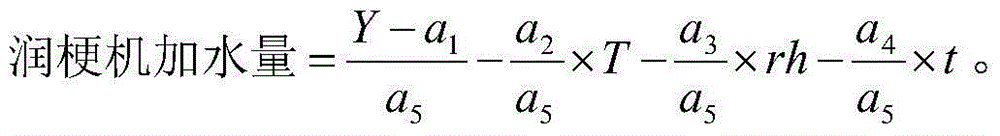

[0020] The moisture content of cut tobacco stems is a very important factor affecting the smoking quality and physical and chemical properties of finished cigarettes during the production of tobacco processing thread. In the processing and production of tobacco stems, the tobacco stems are cleaned by a steeping machine to remove the dust on the stems, and then enter the stemming machine to add water to moisten the stems, and then enter the stem storage cabinet after processing. After the stems are stored, they enter the stem cutting machine for processing. Cut into shreds, and feed through the stalk feeder after shredded. In this process, the stem moistening machine adds water to the tobacco stems, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com