Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

A technology of moisture-conducting polyester and processing technology, applied in the direction of warp knitting, fiber type, textile material processing, etc., can solve the problems of restricting product grade, low product grade, softness, warmth retention, skin-friendly, poor comfort, etc. , to achieve the effect of improving grade and added value, excellent flexibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

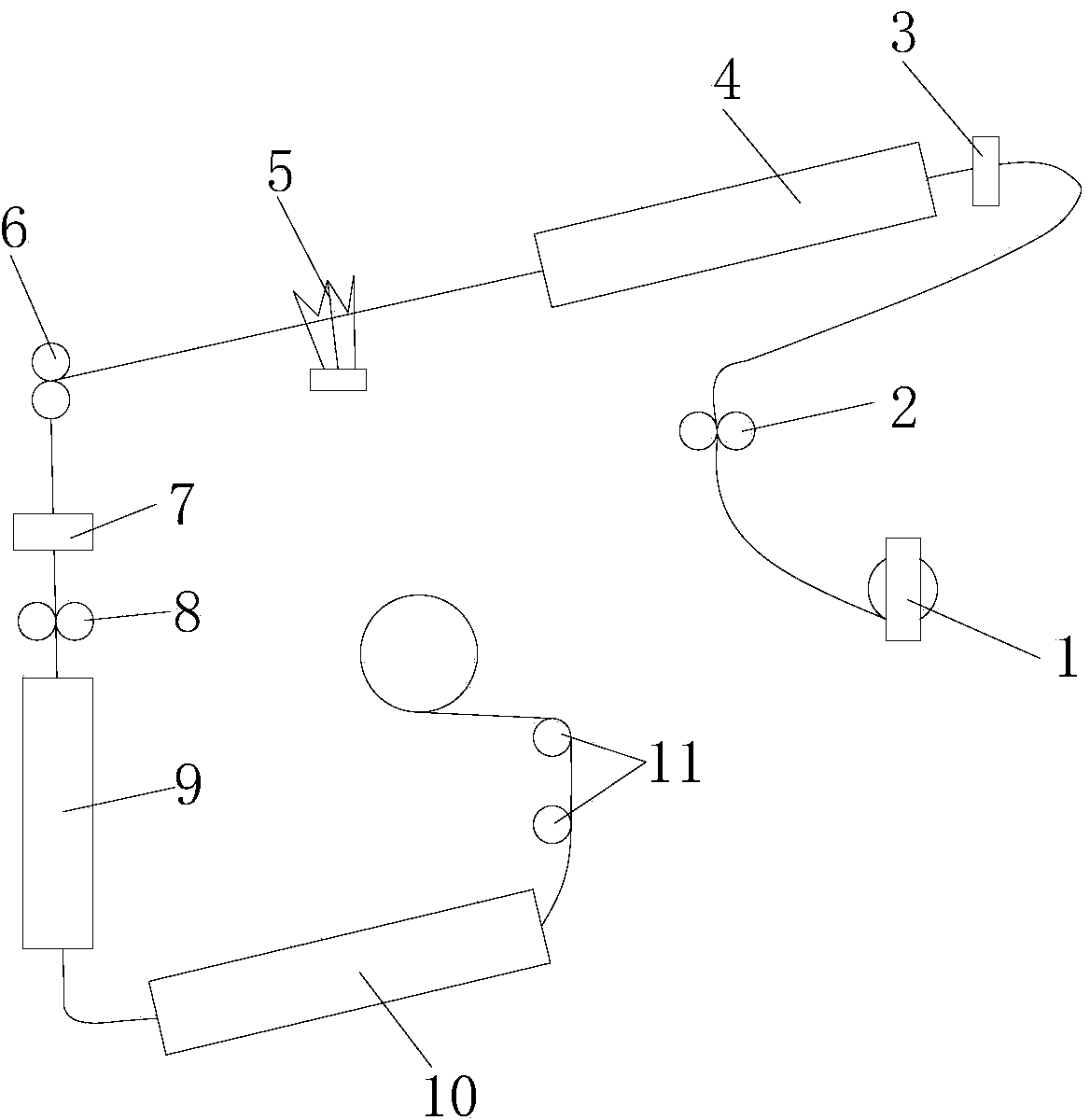

[0022] refer to figure 1 , a kind of ultra-imitation cotton / fine denier moisture-conducting polyester comfortable type mercerized velvet warp knitted fabric processing technology of the present invention comprises the following steps in turn:

[0023] a): Super-imitation cotton fiber process: Super-imitation cotton fiber is processed by adjusting the aggregated structure of the fiber material and controlling the surface morphology of the composite filament, and then it is improved through spinning, stretching, and deformation processes in sequence Super imitation cotton fiber performance;

[0024] b) Textile process of fine denier moisture-conducting and texturing polyester filament: the fine-denier moisture-conducting and texturing polyester filament is 43dtex / 72f fine denier moisture-conducting and texturing polyester filament, which is processed by texturing machine equipment to form 43dtex / 72f fine Moisture-conducting and textured polyester filaments, the raw yarn 1 passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com