Liquid dispensing device with connecting portion with radial slots and galvanized central shaft

A technology of central shaft and connecting part, applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve the problem of not having regular manual maintenance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Attached below Figure 1-5 , the present invention will be described in detail.

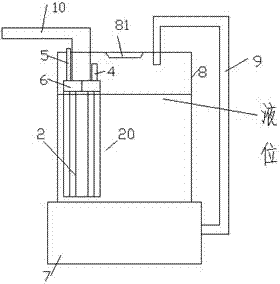

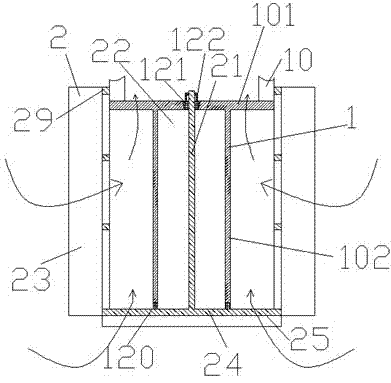

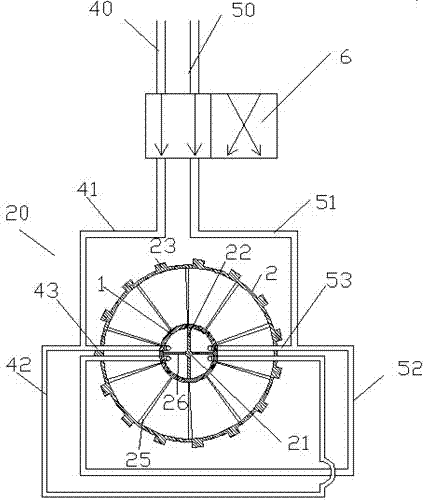

[0021] A device for supplying liquid by air pressure with a radially extending connecting portion with a radially long and narrow slot and a central shaft with an electroplating coating, including a pressure air supply device 7, a pressure chamber 8, a pressure supply pipe 9, a liquid supply The outlet pipeline 10 and the suction filter device 20, wherein the pressure air supply device 7 is used to provide pressure for the pressure chamber 8 through the pressure supply pipe 9, and the pressure chamber 8 can increase the liquid in the pressure chamber 8 pressure and sent out through the liquid supply pipeline 10, the suction filter device 20 is arranged at the inner end of the liquid supply pipeline 10, and is used to filter the liquid when the liquid supply pipeline 10 draws the liquid from the pressure chamber 8 Filtration; the outer end of the liquid supply pipe 10 is used to flow out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com