Press fitting mechanism for automatic measurement riveting machine of plunger steel ball

An automatic measurement and plunger steel ball technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the steel ball is easy to fall out and cannot guarantee the firmness of the connection between the steel ball and the plunger, so as to ensure stability and prolong The effect of improving the service life of equipment and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

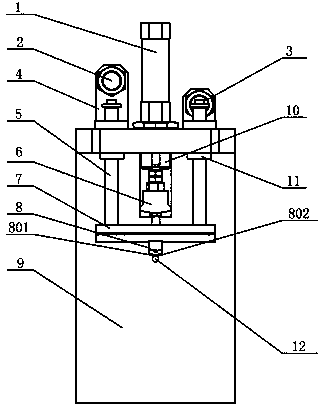

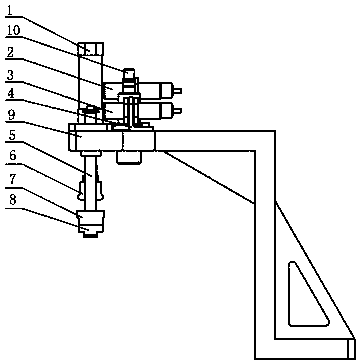

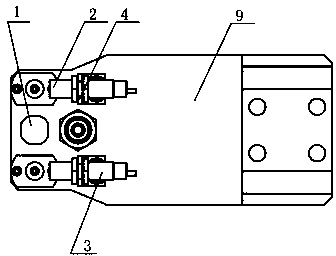

[0024] Such as figure 1 , figure 2 and image 3 As shown, a press-fitting mechanism for plunger steel ball automatic measuring riveting press includes a mounting base 9, which is in a "Z" shape, and a pneumatic lifting unit and a sensing unit are respectively installed on the mounting base 9;

[0025] The specific structure of the pneumatic lifting unit is as follows:

[0026] Including the cylinder 1, the output end of the cylinder 1 runs through the mounting seat 9 and connects to the floating joint 6, the floating joint 6 abuts against the guide plate 7, and the guide plate 7 is located below the floating joint 6, on both sides of the cylinder 1, on the mounting seat 9 A guide post 5 is installed on the top, and a guide sleeve 11 is installed on the outer periphery of the guide post 5 . The end of the guide post 5 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com