Buffering spray gun assembly

An assembly and spray gun technology, applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve the problems of spray gun vibration, severe vibration, unevenness, etc., and achieve the effects of reducing mutual wear, reducing pulse frequency, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the specific drawings and embodiments.

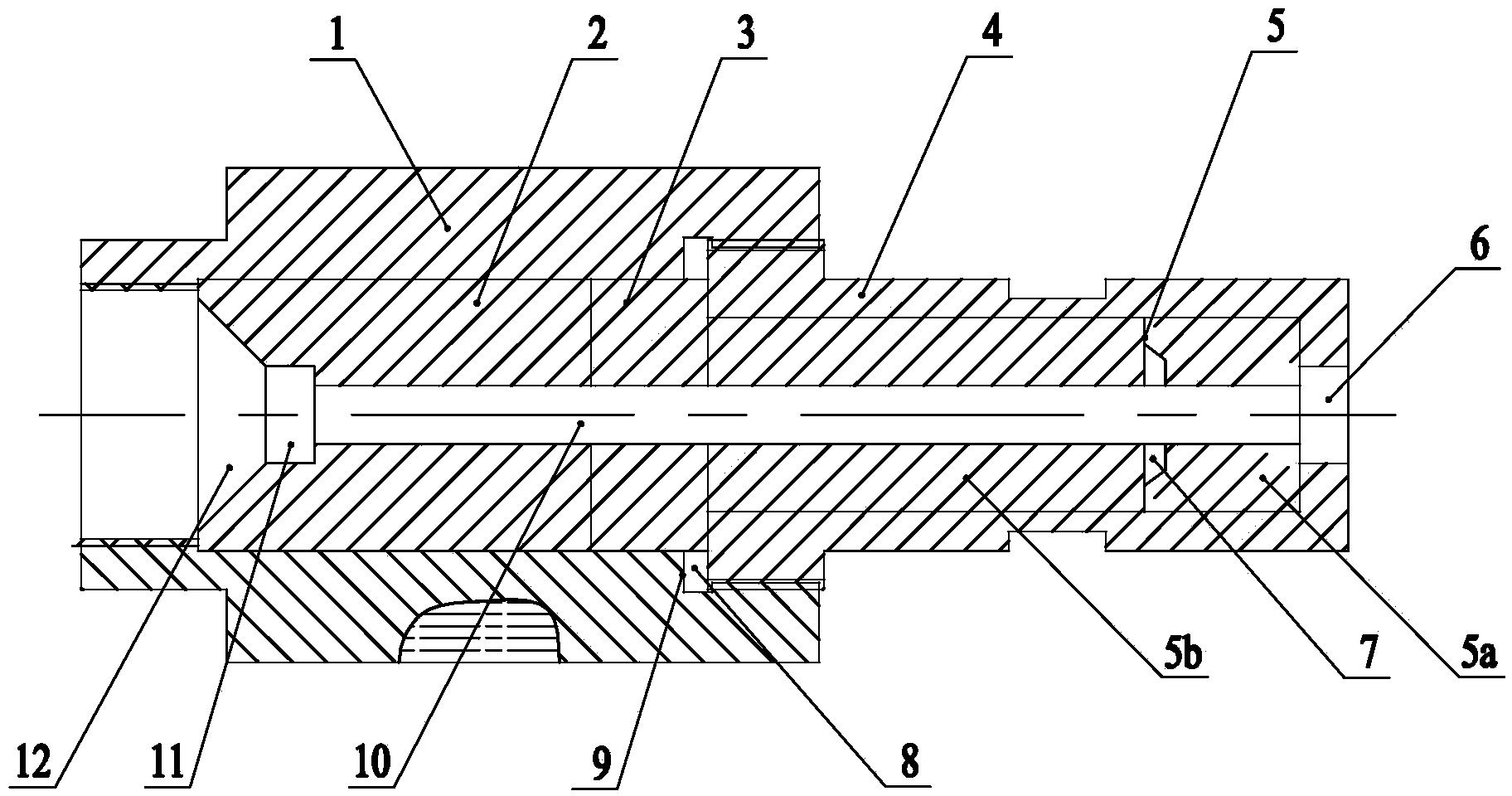

[0015] As shown in the figure: the buffer spray gun assembly in the embodiment is mainly composed of a spray head connecting sleeve 1, a spray sleeve 2, a buffer joint 3, a spray head locking sleeve 4, a nozzle 5 and an O-ring 8.

[0016] like figure 1 As shown, the nozzle sleeve 2 is arranged in the nozzle connecting sleeve 1, the rear end of the nozzle connecting sleeve 1 is provided with an interface for connecting the steel shot input pipeline, the front end of the nozzle connecting sleeve 1 is connected to the nozzle locking sleeve 4, and the nozzle 5 is placed in the nozzle. In the inner cavity of the locking sleeve 4, a buffer joint 3 is sandwiched between the rear end surface of the nozzle 5 and the front end surface of the spray sleeve 2, and the center of the spray sleeve 2, the buffer joint 3 and the nozzle 5 is provided with a central through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com