Production device for insulating bricks

A technology for production equipment and thermal insulation bricks, which is applied in the field of composite thermal insulation building materials manufacturing, can solve the problems of cracks and structural strength of porous bricks, and achieve the effects of avoiding fine pores, high fusion strength, and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0033] A kind of production technology of insulation brick that the present invention relates to, comprises the following steps:

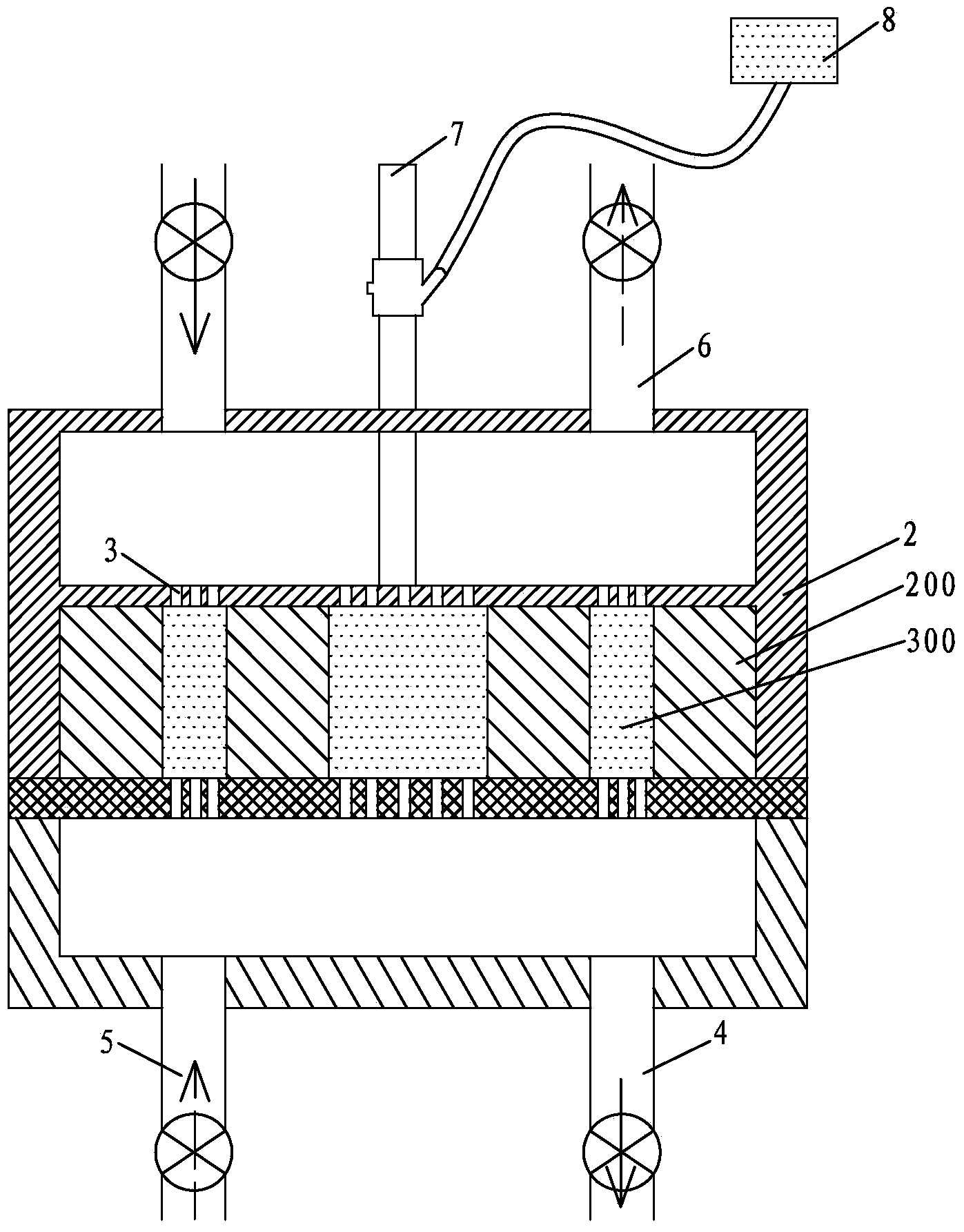

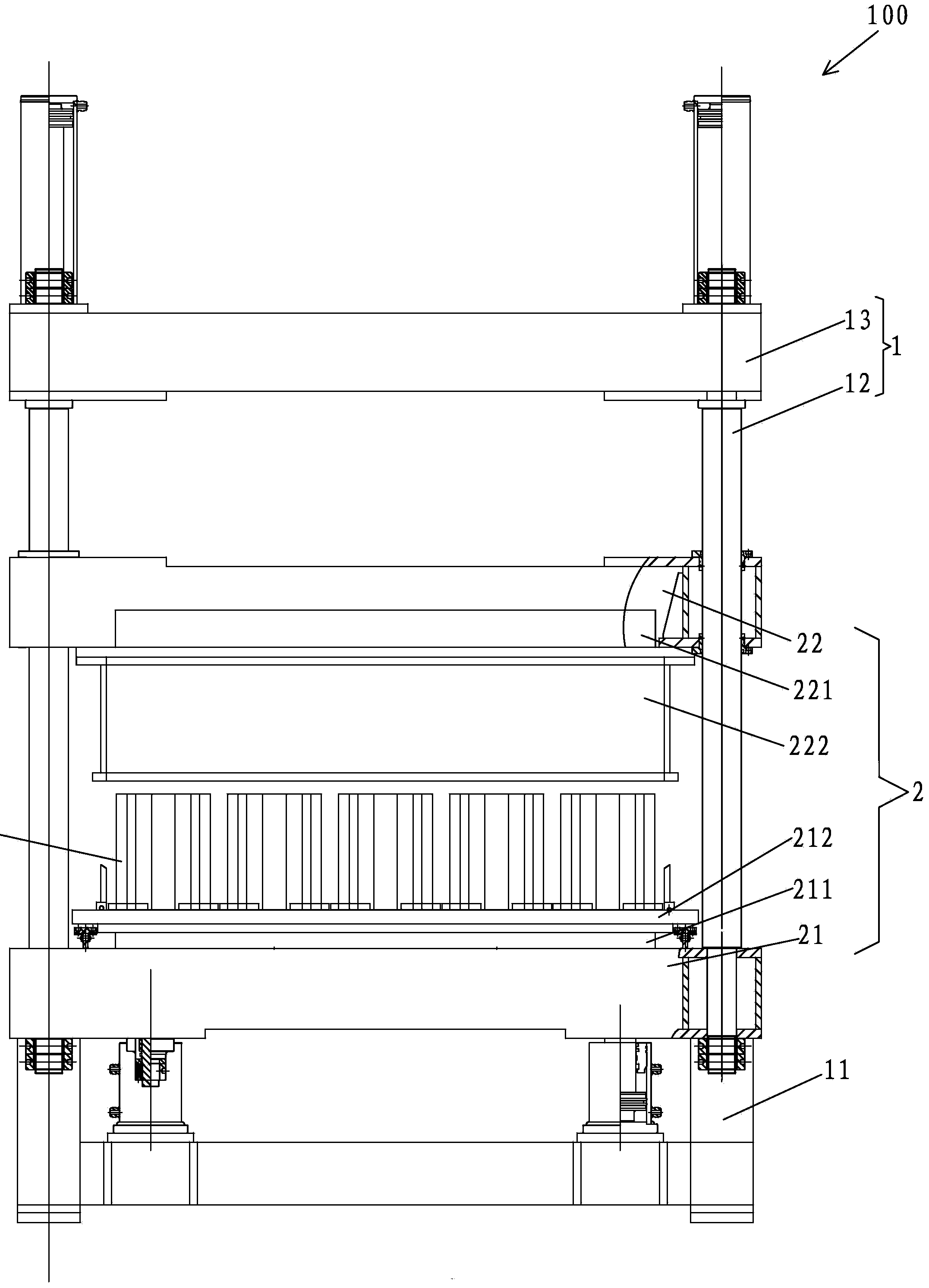

[0034] ①. Put the porous brick 200 into the container 2, and fill the brick holes or grooves on the porous brick 200 that need to be filled with thermal insulation materials with polystyrene foamed particles 300; That is, the polystyrene foam particles 300 located in the feed bin 8 are injected into the brick holes or grooves through the material gun 7, so that compared with the previous technology, it can also prevent the polystyrene foam particles 300 from It has the characteristics of simple operation process and high molding efficiency;

[0035] Specifically, the position where the porous brick 200 is set in the container 2 needs to meet the following two conditions, namely con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com