Waste mineral oil cycle flash evaporation catalytic cracking recovery process

A waste mineral oil, catalytic cracking technology, applied in the direction of only multi-stage series refining and cracking process, dehydration/demulsification by mechanical method, etc., can solve the pollution of tail gas emission, waste of energy and water resources, and low recovery efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

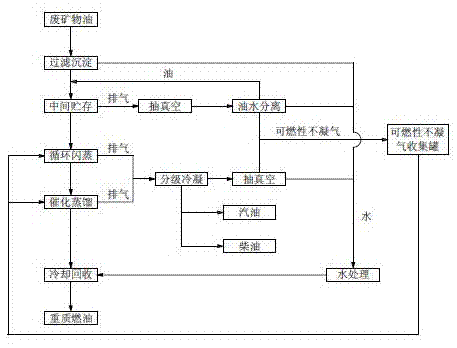

[0021] Such as figure 1 Shown, waste mineral oil circulating flash catalytic cracking recovery process, comprises the following steps:

[0022] A. Filtration and sedimentation: put the waste mineral oil into the filtration sedimentation tank and pass through 80-100 mesh filter screen to filter and settle for 2-7 days. to water treatment equipment.

[0023] B. Intermediate storage: vacuumize the oil storage tank with a vacuum degree of -0.01MPa, and separate the extracted gas from oil and water, return the separated oil to the oil storage tank, send the water to the water treatment equipment, and send the flammable non-condensable gas to the storage tank. To the flammable non-condensable gas collection tank.

[0024] C. Circulation flash evaporation: Put the waste mineral oil in the oil storage tank into the flash tank. When the waste mineral oil reaches a certain amount, run the circulation pump, gas heating furnace and vacuum pump to remove the waste mineral oil in the fla...

Embodiment 2

[0029] The waste mineral oil circulation flash catalytic cracking recovery process includes the following steps:

[0030] A. Filtration and sedimentation: put the waste mineral oil into the filtration sedimentation tank and pass through 80-100 mesh filter screen to filter and settle for 2-7 days. to water treatment equipment.

[0031] B. Intermediate storage: vacuumize the oil storage tank, the vacuum degree is -0.02MPa, and separate the oil and water from the extracted gas, return the separated oil to the oil storage tank, send the water to the water treatment equipment, and send the flammable non-condensable gas To the flammable non-condensable gas collection tank.

[0032] C. Circulation flash evaporation: Put the waste mineral oil in the oil storage tank into the flash tank. When the waste mineral oil reaches a certain amount, run the circulation pump, gas heating furnace and vacuum pump to remove the waste mineral oil in the flash tank. Circulating flash evaporation for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com