Tire burst monitoring sensor

A technology for monitoring sensors and tires, applied in the field of sensors, can solve the problems of driver inconvenience and pressure difference, and achieve the effect of good operation performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

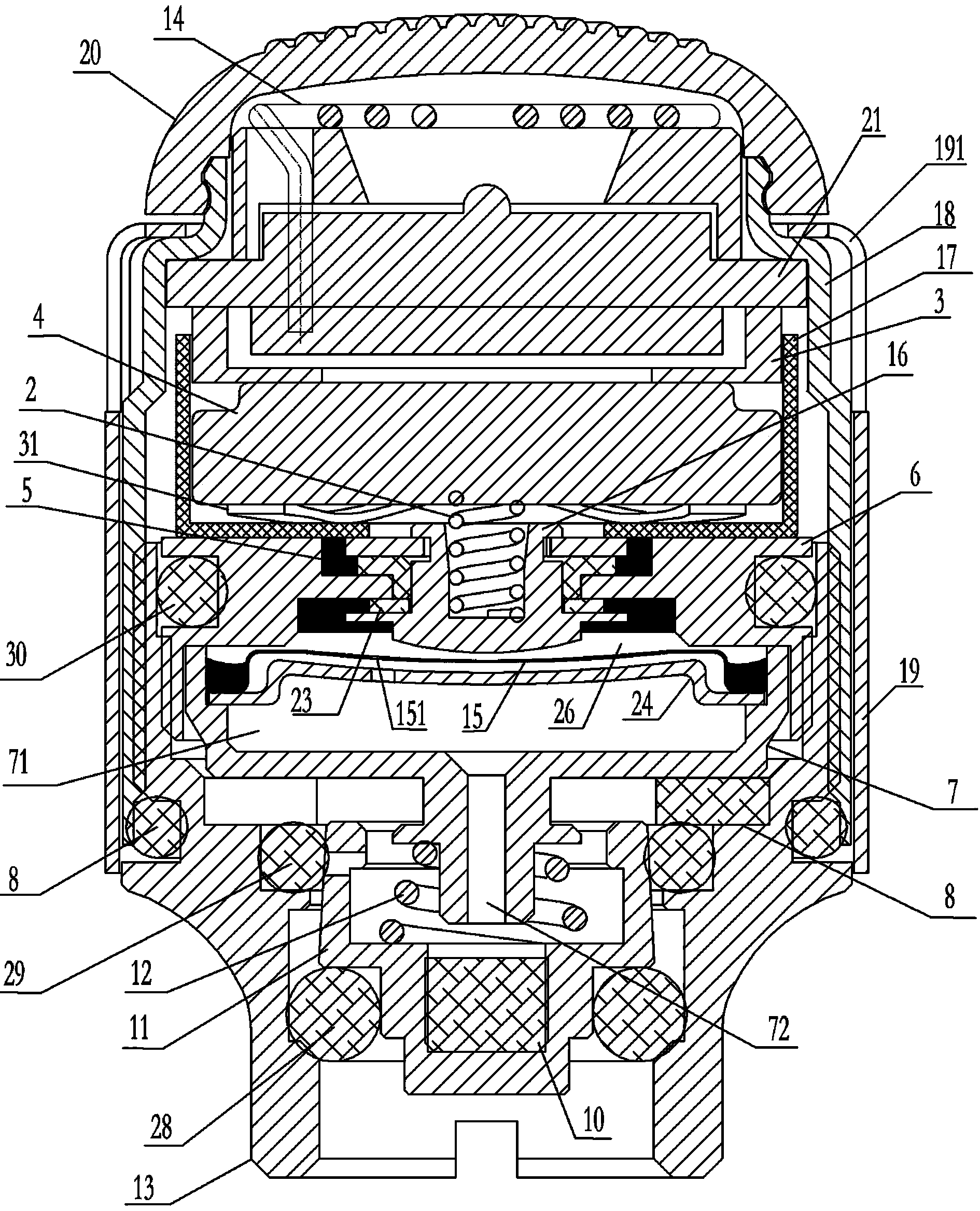

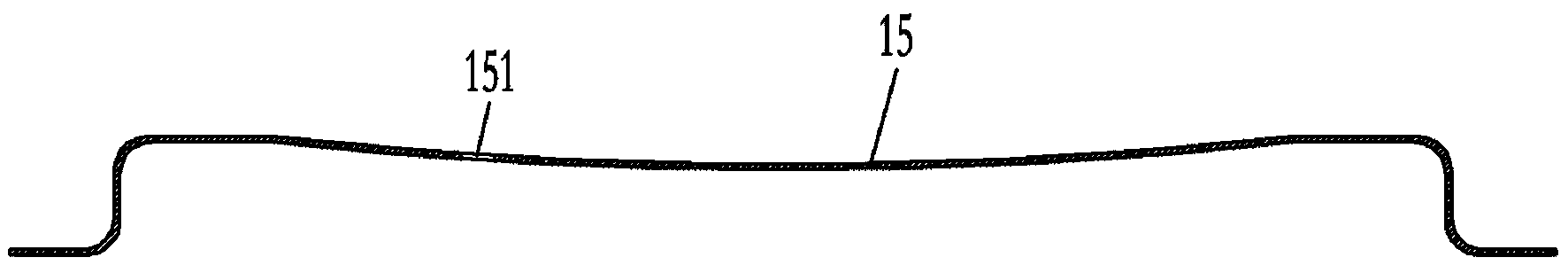

[0011] like figure 1 As shown, the tire puncture monitoring sensor includes a bottom nut 13 that can be screwed on the tire valve core (not shown in the figure) and a housing 18 screwed on the bottom nut 13. The bottom of the housing 18 passes through a sealing ring 8 is sealed with the bottom nut 13, there is a lens 20 on the top of the casing 18, the lens 20 seals the top of the casing 18 from the outside world, the inner space formed by the casing 18 and the bottom nut 13 is from top to bottom, and the alarm circuit board 21, the battery are installed 4. The elastic conductive sheet 15, the reference cavity assembly 7 and the top spring 12; the alarm circuit board 21 can be the transmitting module and the transmitting antenna 14 connected to it, and the positive lead-in end of the alarm circuit board 21 is directly or through the conductive member 3 and the battery below it The positive pole of 4 is turned on, and the negative pole of the alarm circuit board 21 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com