Self-aerating and pressure-regulating device for rubber tire road roller

A technology for a rubber-tired road roller and a pressure regulating device, which is applied to roads, roads, road repairs, etc., can solve problems such as affecting work efficiency, affecting construction quality, and unable to adjust pressure independently, so as to improve construction quality, improve inflation methods, and avoid problems. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

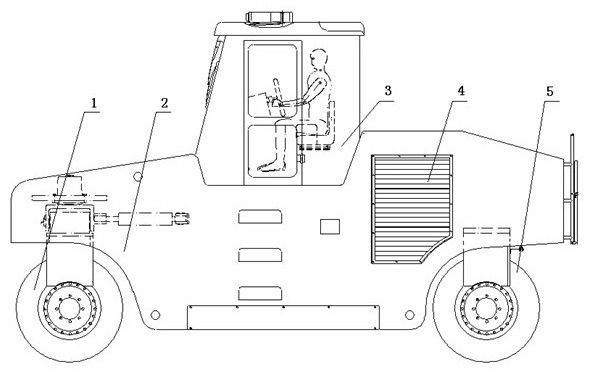

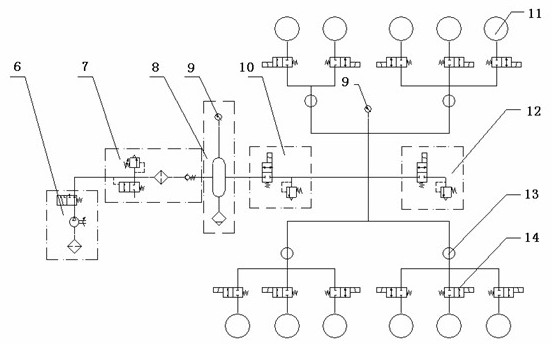

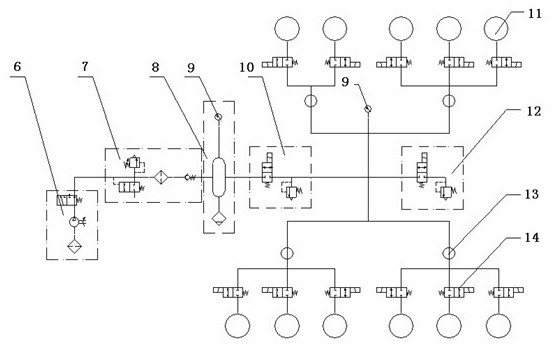

[0015] Such as figure 1 and figure 2 As shown, the present invention includes a front wheel assembly 1, a frame 2, a cab assembly 3, a power system 4 and a rear wheel assembly 5, and also includes an air circuit system, which includes an air compressor 6, a pressure valve group 7. Inflatable valve group 10, rotary valve 13, air tank assembly 8, pressure gauge 9, rubber wheel 11, electromagnetic reversing valve 14 and deflation valve group 12, and the air tank assembly 8 is respectively located at one end of the pressure valve group 7, the inflation One end of the valve group 10 is connected to a pressure gauge 9, the other end of the pressure valve group 7 is connected to the air compressor 6, and the other end of the inflation valve group 10 is respectively connected to another pressure gauge 9, one end of a plurality of rotary valves 13 and the discharge valve. The air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com