Preparation method of iron selenide/carbon composite material

A technology of carbon composite materials and iron selenide, which is applied in the field of ceramics, can solve problems such as increased dependence and resource shortage, and achieve the effects of enhanced electrical conductivity, faster charge transfer speed, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Disperse dopamine hydrochloride and ferric ammonium oxalate in isopropanol solution at a mass ratio of 3:1, stir on a magnetic stirrer at a speed of 200r / min for 24 hours to mix evenly to dissolve dopamine hydrochloride, keep ferric ammonium oxalate insoluble, and obtain a light green color The suspension was filtered by suction and evaporated to dryness to obtain light green powder A1.

[0056] Heat the powder A1 in a low-temperature tube furnace at a vacuum degree (about -0.1MPa) from room temperature at 10°C / min to 600°C for 1 hour to obtain iron oxide / carbon precursor powder Body B1.

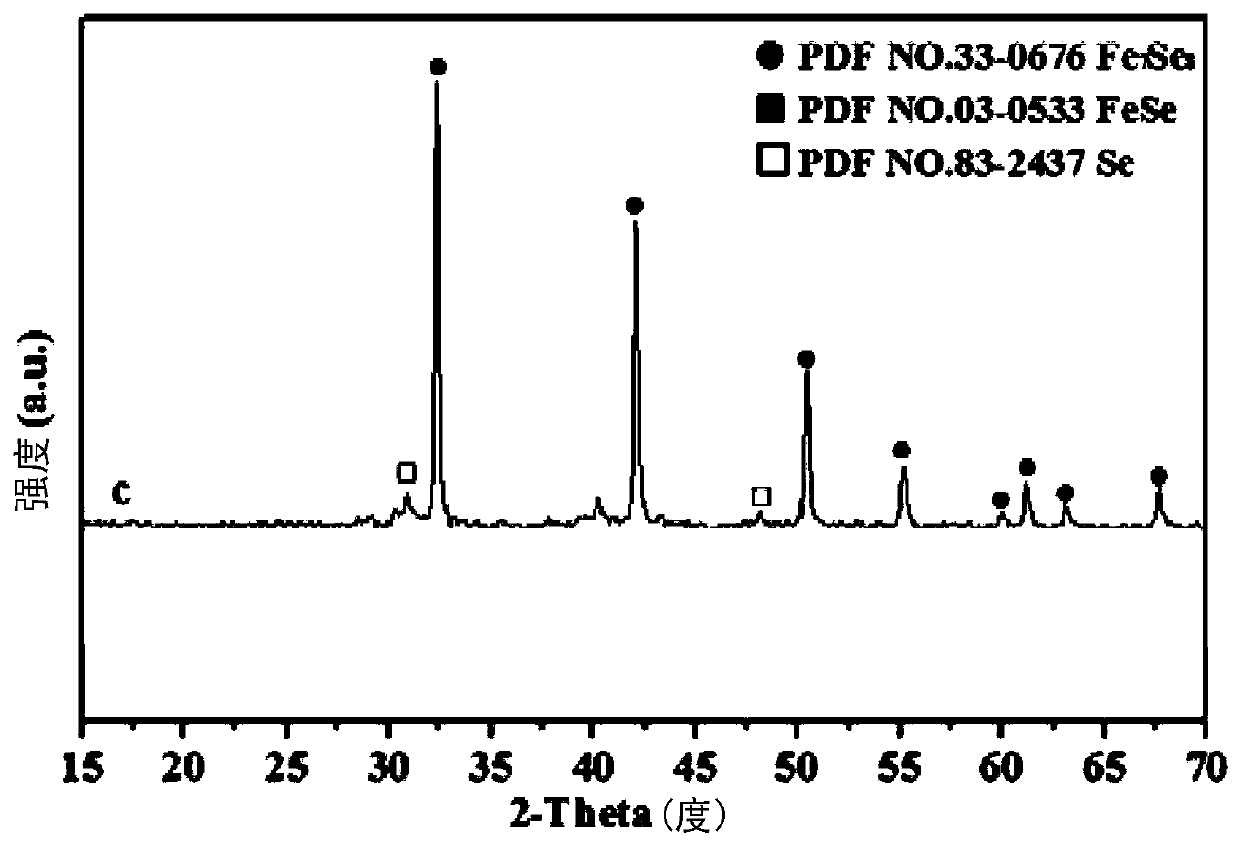

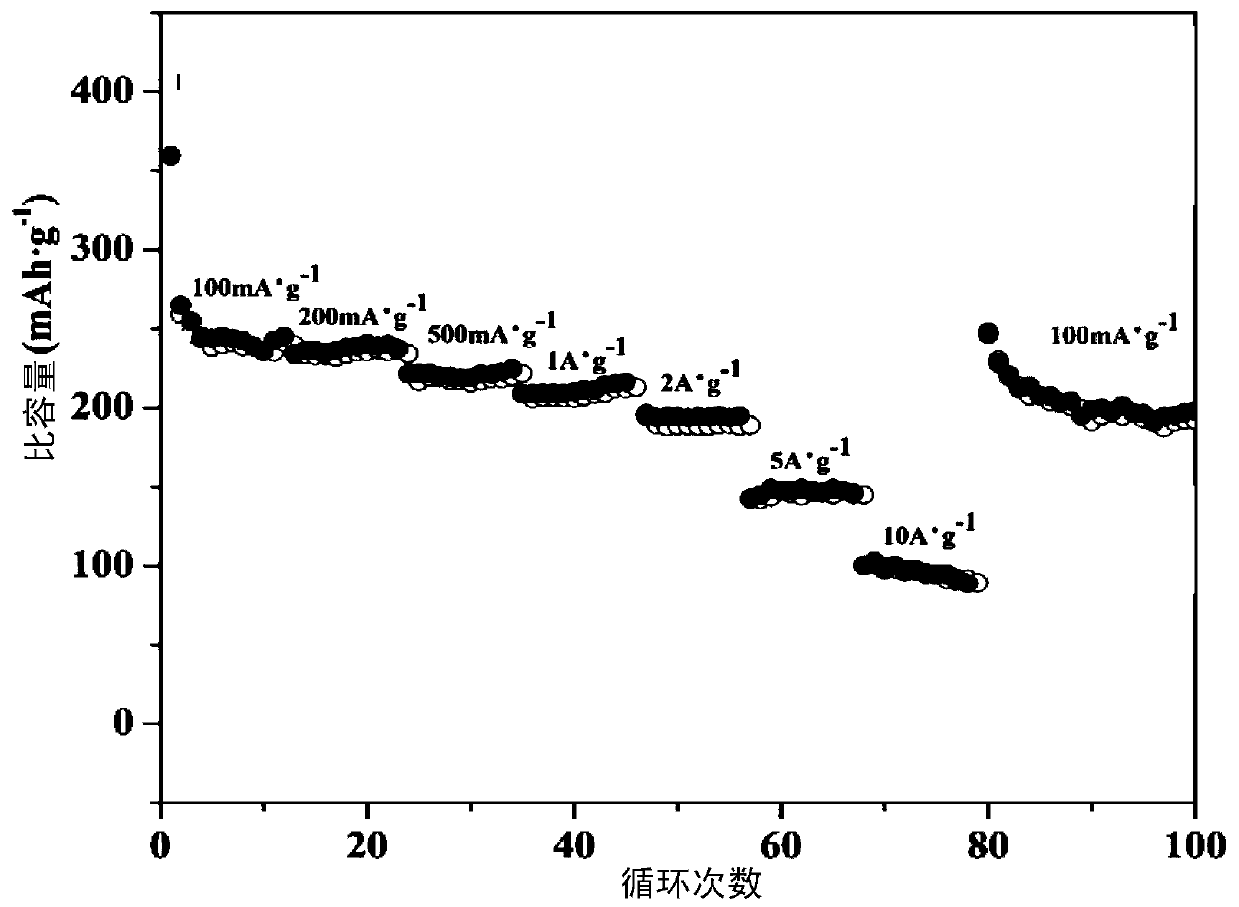

[0057] The product B1 and selenium powder were weighed according to the mass ratio of 1:2, the product B1 and selenium powder were ground and placed in a crucible, put into a tube furnace and vacuumed (the pressure gauge was about -0.1MPa), at 5°C / min The heating rate was increased from room temperature to 600°C, and the temperature was kept for 1 hour. After the heat preservation wa...

Embodiment 2

[0060] Disperse dopamine hydrochloride and ferric ammonium citrate in isopropanol solution at a mass ratio of 5:1, stir on a magnetic stirrer for 18 hours and mix evenly to obtain a light green suspension. The solution is filtered by suction and evaporated to dryness to obtain a light green powder Body A2.

[0061] Heat the powder A2 to 700°C for 1 hour from room temperature at 15°C / min in a low-temperature tube furnace under the condition of a vacuum degree (the pressure gauge is about -0.08MPa) to obtain Fe 3 o 4 / C precursor powder B2.

[0062] The product B2 and selenium powder were weighed according to the mass ratio of 1:3, the product B and the selenium powder were ground and placed in a crucible, put into a tube furnace and vacuumed (the pressure gauge was about -0.08MPa), at 7°C / min The heating rate was increased from room temperature to 700°C, and the temperature was kept for 1 hour. After the heat preservation was completed, argon gas was added to make the pressur...

Embodiment 3

[0065] Disperse ferric oxalate and dopamine hydrochloride in isopropanol solution at a mass ratio of 8:1, stir on a magnetic stirrer for 24 hours and mix evenly to obtain a light green suspension. The solution is filtered by suction and evaporated to dryness to obtain a light green powder A3 .

[0066] The powder A3 is heated in a low-temperature tube furnace at a vacuum degree (about -0.06MPa on the pressure gauge) from room temperature at 7°C / min to 500°C for 1 hour to obtain Fe 3 o 4 / C precursor powder B3.

[0067] The product B3 and selenium powder were weighed according to the mass ratio of 1:5, the product B3 and selenium powder were ground and placed in a crucible, put into a tube furnace and vacuumed (the pressure gauge was about -0.07MPa), at 15°C / min The heating rate was increased from room temperature to 900°C, and the temperature was kept for 1 hour. After the heat preservation was completed, argon gas was added to make the pressure in the tube zero. The layere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com