Temperature control inflating device for sulfur hexafluoride

A technology of an inflatable device and a temperature control device, which is applied to container filling methods, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., and can solve the problems affecting the normal operation of high-voltage electrical equipment, the increase of air pressure of high-voltage electrical equipment, and the inflatable pipeline. Easy to condense and other problems, to achieve maximum practical and promotional value, to prevent internal air pressure from rising, to eliminate the effects of air and its contained moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

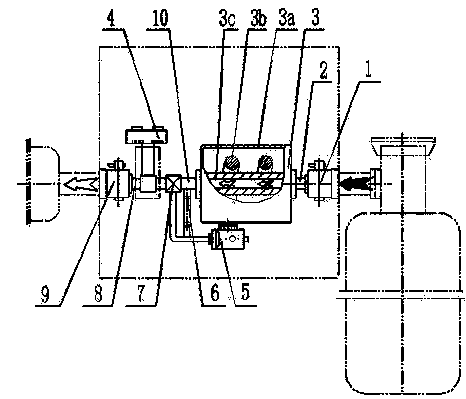

[0011] Referring to the accompanying drawings, a sulfur hexafluoride temperature-controlled inflation device of the present invention consists of an air inlet joint valve 1, a gas pipe I2, a heating device 3, a vacuum pressure controller 4, a temperature control device 5, a temperature control probe 6, a temperature control Valve 7, air pipe II 8, air outlet joint valve 9 and air pipe III 10 are characterized in that: the heating device 3 is connected to the air inlet joint valve 1 through the air pipe I2; the temperature control device 5 is connected to the heating device 3; the temperature control probe 6 is connected to the The air pipe III10 is connected to the temperature control device 5; the vacuum pressure controller 4 is connected to the outlet joint valve 9 through the air pipe II8; the temperature control valve 7 is connected to the air pipe II8 and the air pipe III10, and connected to the temperature control device 5; The heating device 3 is composed of an outer she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com