A fixed structure of the front air suspension of a two-stage stepping bus

An air suspension and two-stage stepping technology, applied in the field of buses, can solve the problems that the seat cannot meet the riding comfort, affect the speed of passengers getting on and off the bus, and the design of the fixed structure is complicated, so as to meet the needs of riding comfort and improve the speed of getting on and off The effect of vehicle speed and stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

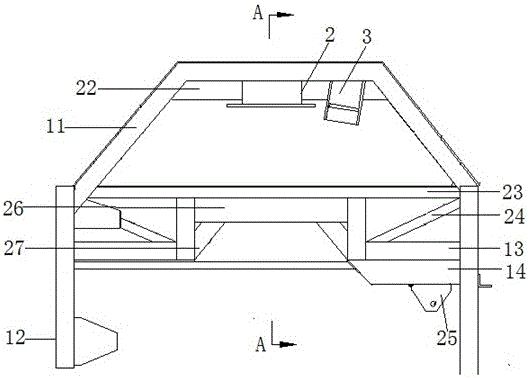

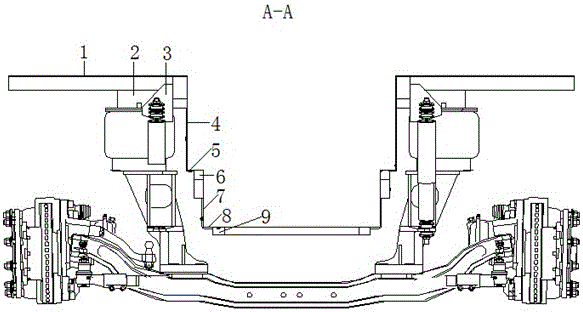

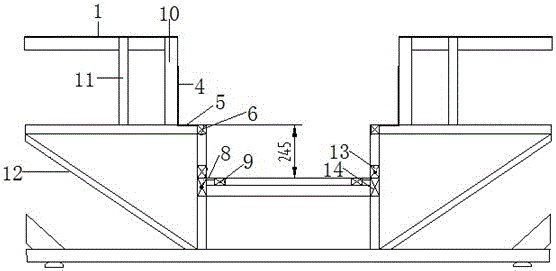

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as Figure 1-Figure 6 The fixed structure of the front air suspension of a two-stage stepping bus shown includes a wheel cover assembly and a walkway assembly located above the air suspension. The wheel cover assembly includes a left wheel cover assembly and a right wheel cover assembly with a height of 400mm symmetrically distributed on both sides of the walkway assembly. Preferably, the heights of the left wheelhouse assembly and the right wheelhouse assembly are both 400mm. Three seats with a seat height of 450mm can be installed above the left wheelhouse assembly and the right wheelhouse assembly. The aisle width is 720mm. The left wheel house assembly and the right wheel house assembly have the same structure, respectively comprising a wheel house bracket fixed above the vehicle body frame, a wheel cover upper seal plate 1 fixed above the wheel house bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com