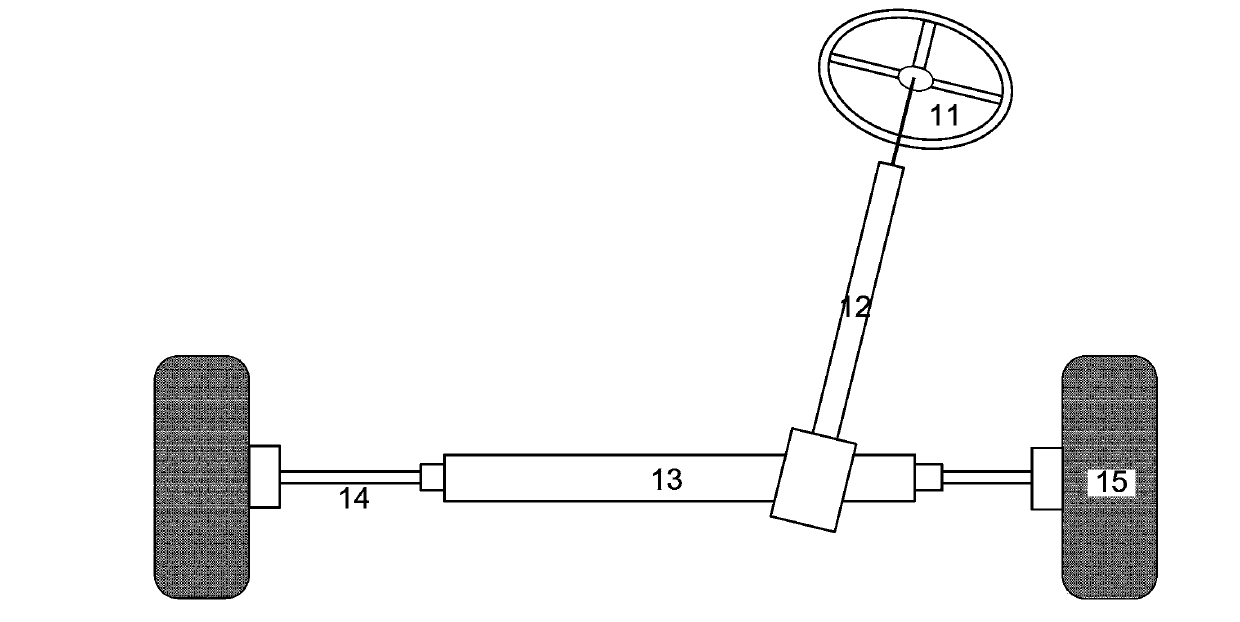

Rack end protection method of electric power steering system

An electric power steering and end protection technology, applied in electric steering mechanism, automatic steering control components, steering mechanism, etc., can solve problems such as reduced protection effect, increased cost, noise and discomfort for drivers and passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

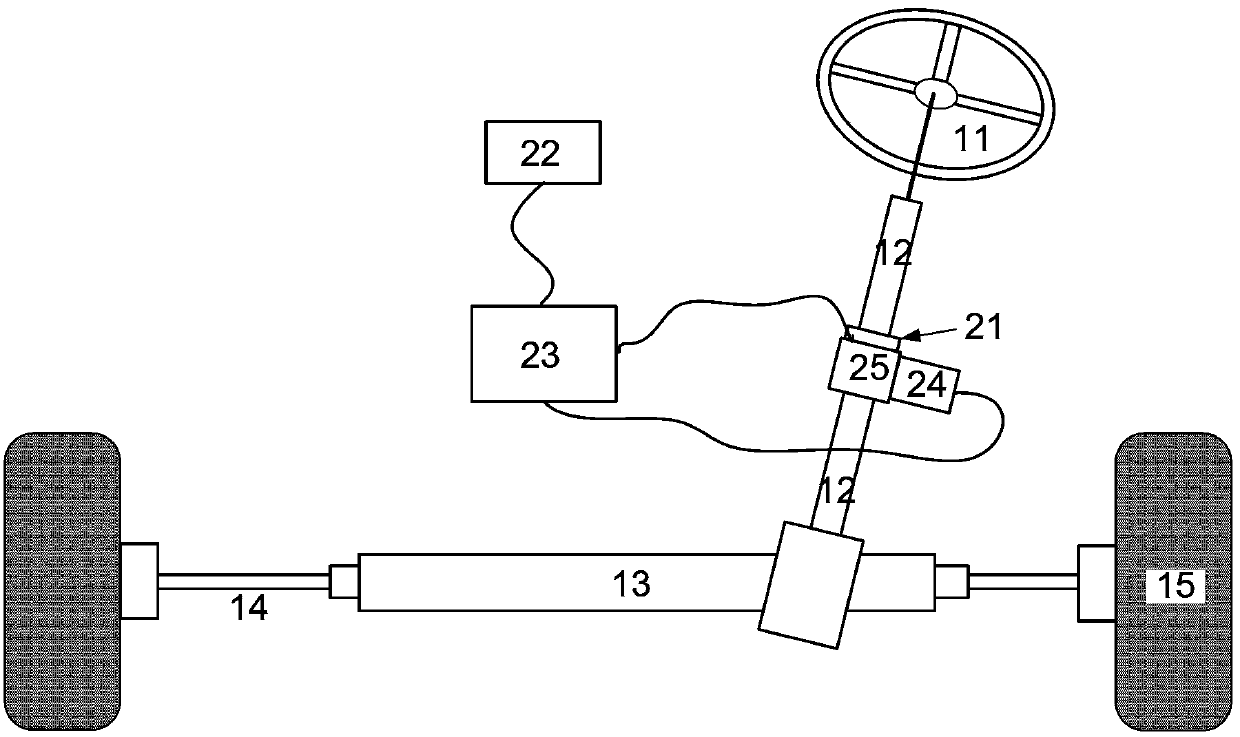

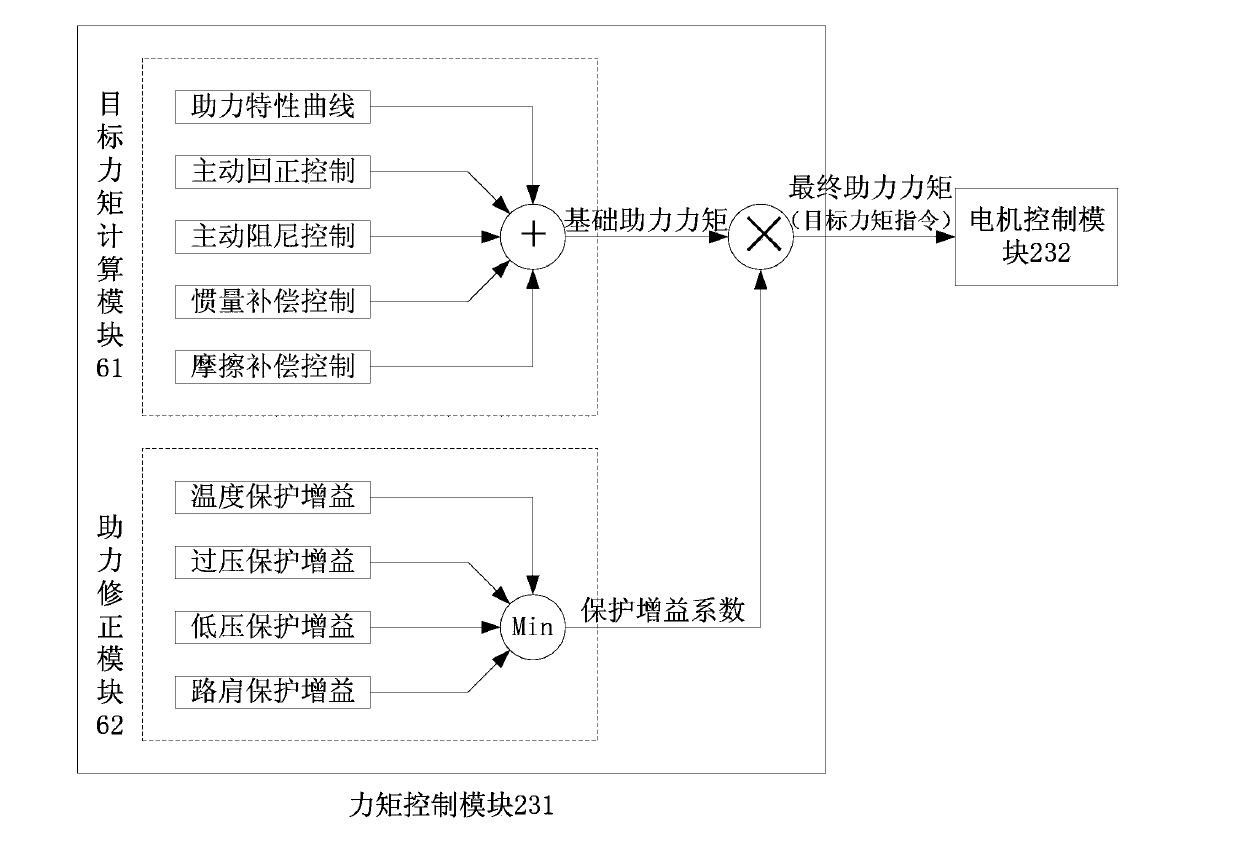

[0040] see Figure 4 , which is the torque control module of the electric power steering system of the present application. and image 3 Compared with the existing torque control module shown, the present application adds a rack end protection gain module in the power assist correction module 62 .

[0041] see Figure 5 , the rack end protection method of the electric power steering system of the present application is: when the rack of the steering gear 13 moves toward the rack end and enters the rack end protection area, the rack end protection gain module uses the steering wheel The rotation angle, rotation angular velocity and rotation torque of 11 are used as input, and the gain value of rack end protection is output after calculation. After the rack end protection gain value is multiplied by the base assist torque calculated by the target torque calculation module 61 , it is output to the motor control module 232 as a final target torque command.

[0042] Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com