Rear shock absorber mounting base structure of motorcycle frame

A shock absorber and mounting seat technology, which is applied in the field of motorcycle rear shock absorber mounting seat structure, can solve the problems of poor safety performance, increased safety hazards, small welding area, etc., and achieve connection strengthening Good effect, increase welding precision, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

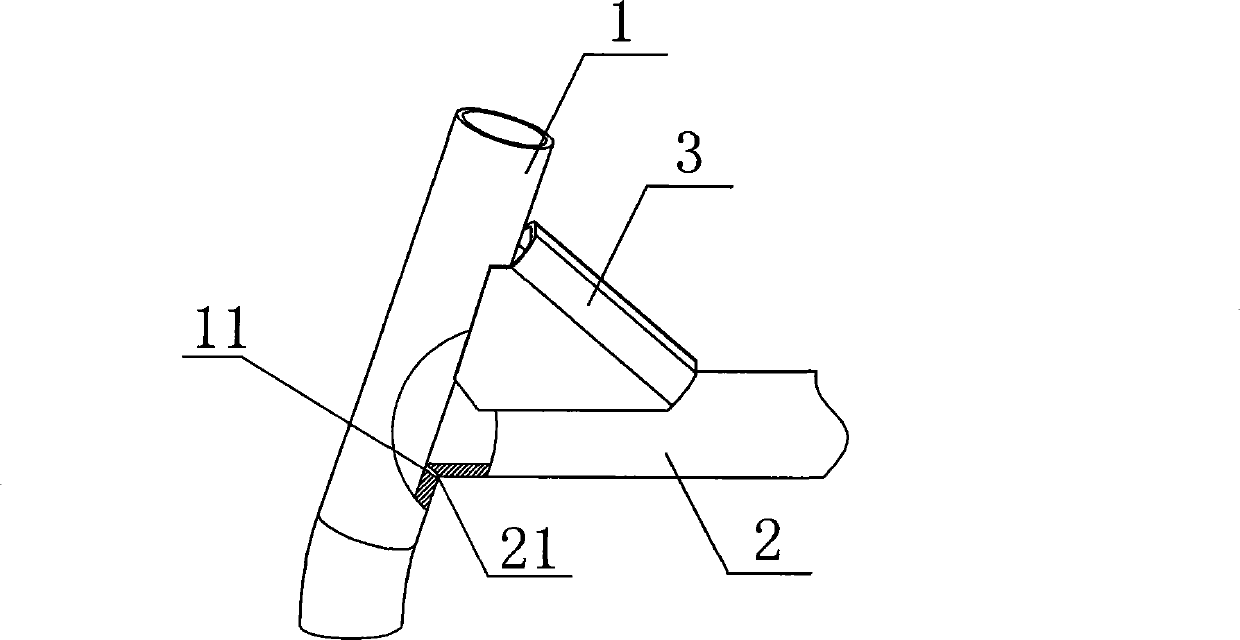

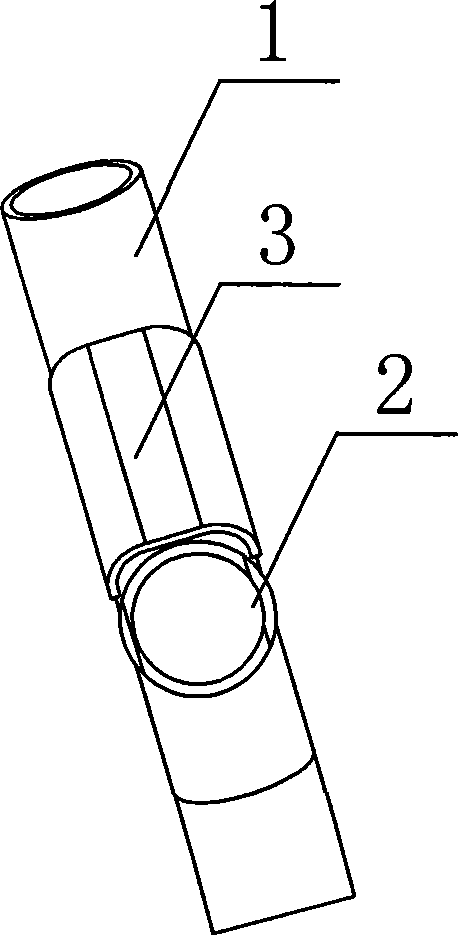

[0011] See attached figure 1 , 2 , motorcycle rear shock absorber mount structure of the present invention, it comprises vehicle frame pipe 1 and cross pipe 2, and the end of cross pipe 2 is fixed on the middle part of vehicle frame pipe 1 by welding; Said vehicle frame pipe 1 and cross pipe A reinforcing plate 3 is welded within the acute angle enclosed by the tube 2. The cross-sectional shape of the reinforcing plate 3 is triangular, and the longitudinal section of the reinforcing plate 3 is U-shaped, which ensures the largest possible contact area with the frame. Seeing that the reinforcing plate is triangular, the principle of better ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com