Slide block mechanism for slide block sorting machine of logistics automatic conveying line

A technology of logistics automation and conveying line, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high assembly requirements, high installation accuracy of guide rails and sliders, and low elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

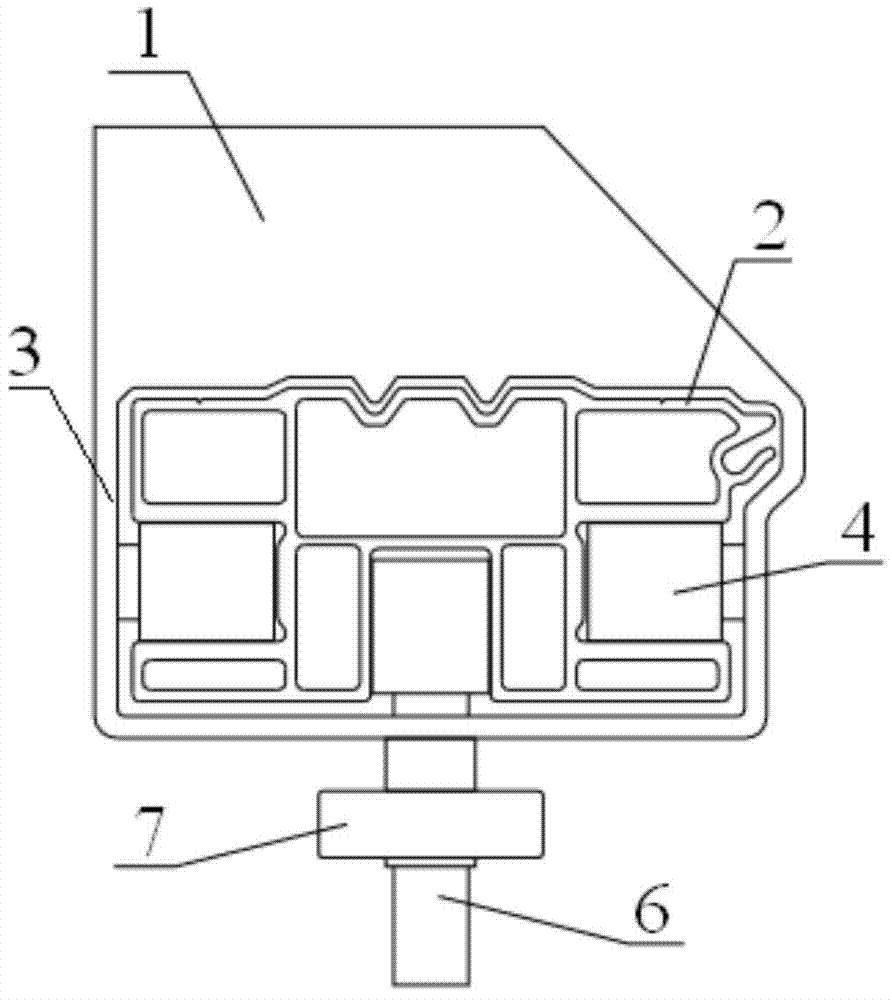

[0028] A slider mechanism for a slider sorter of a logistics automation conveying line, the structure of which is as follows figure 1 As shown, it includes a push hoop, a support plate 2 and a guide device. The push hoop is composed of a hoop push block 1 and a hoop frame 3. The hoop push block 1 is arranged on the top of the hoop frame 3, and the support plate 2 is arranged in the hoop frame 3 to support The upper surface of the plate 2 matches the contour of the lower surface of the hoop push block 1. In this embodiment, the hoop push block and the hoop frame are integrally cast to form an integral casting, and the push hoop encloses and completely covers the support The outer contour of the plate 2, the guide device includes a sliding guide block 4, a guide wheel 7 and a guide pin 6, the sliding guide block 4 is arranged in the support plate 2, specifically, is arranged in the groove inside the support plate 2, the The sliding guide block is a sliding medium between the pus...

Embodiment 2

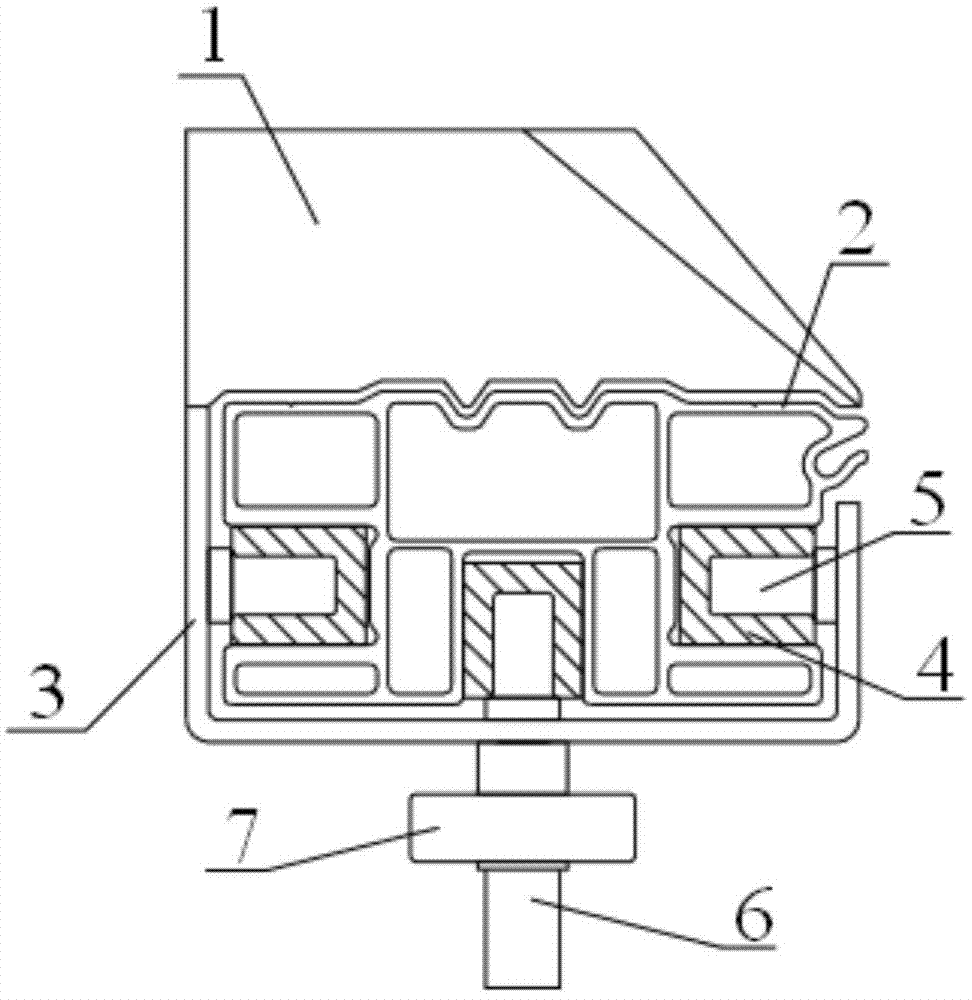

[0030] A slider mechanism for a slider sorter of a logistics automation conveying line, the structure of which is as follows figure 2 As shown, its structure is roughly the same as that of Embodiment 1, the difference is that a guide groove 5 is provided on the left side, the right side and the ground in the hoop frame 3, and the guide groove 5 is inserted into the sliding guide Sliding guide block 4 is positioned in block 4. The guide groove 5 is in the shape of a cylindrical pin, and the sliding guide block 4 is a cuboid structure with a hole in the center, and the guide groove 5 is inserted into the central opening of the slide guide block 4 for positioning. When transferring the product, the hoop pusher block 1 will touch the product. The hoop is pushed to have a movement and the hoop frame 3 will pass through an incline in relation to the support plate 2 . The guide groove 5 located inside the hoop frame 3 will force the sliding guide block 4 into contact with the slid...

Embodiment 3

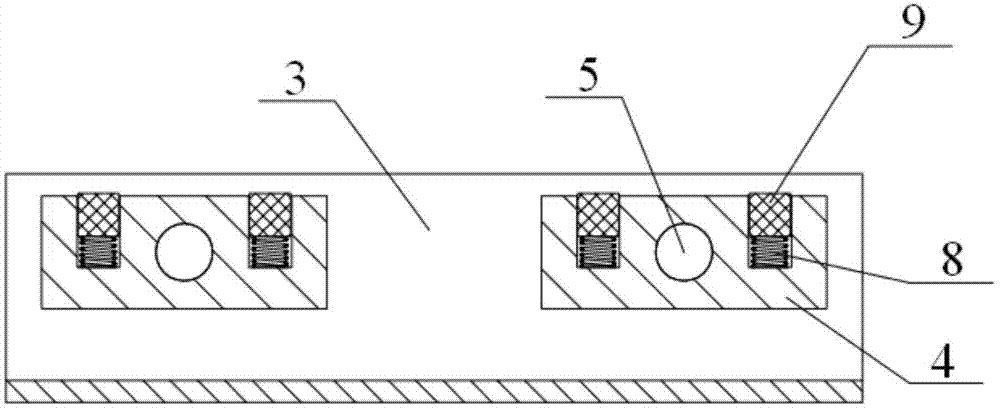

[0032] A slider mechanism for a slider sorter of a logistics automation conveying line, the structure of which is roughly the same as that of Embodiment 2, the difference is that two openings are provided on the sliding guide block 4, and the openings are located on the two sides of the central opening. side, insert a self-expanding device consisting of a spring 8 and a sliding mechanism in the opening, and the sliding mechanism can be a sliding pin 9, such as image 3As shown, the spring 8 is compressed in the opening via the slide pin 9 . When transferring products, the sliding guide block 4 slides in the groove of the support plate 2 . The sliding guide block 4 is matched with the sliding groove of the support plate 2 . When sliding, the gap between the sliding guide block 4 and the support plate 2 will generate vibration and misalignment; this will generate noise and affect the smoothness of sliding. The spring 8 pushes the slide pin 9 out of the top surface of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com