Method for detecting load swinging angle of crane

A detection method and crane technology, applied in the direction of measurement device, measurement angle, mapping and navigation, etc., can solve the problems of load swinging back and forth, load falling, etc., and achieve the effect of high adaptability, low detection power consumption, and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings.

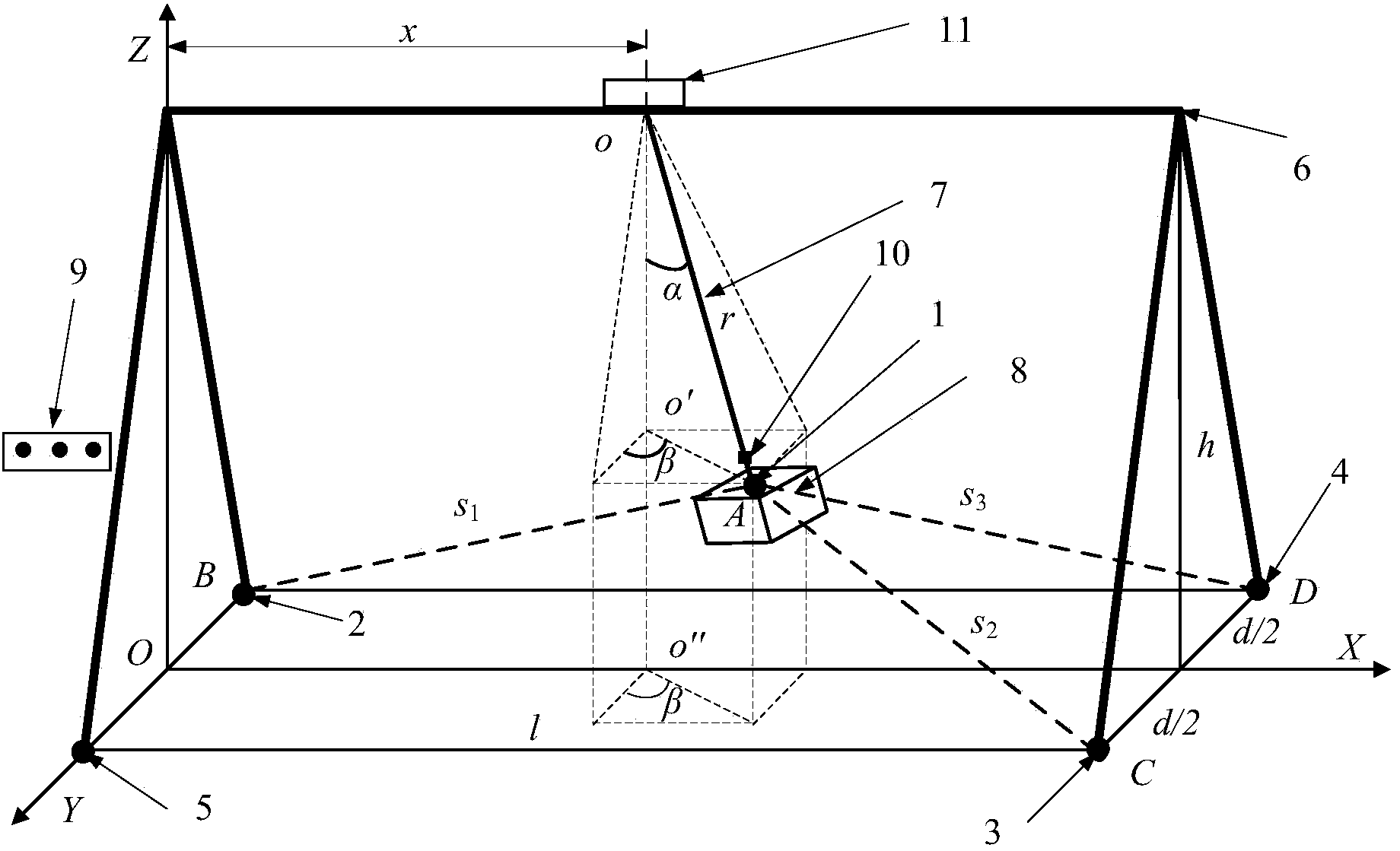

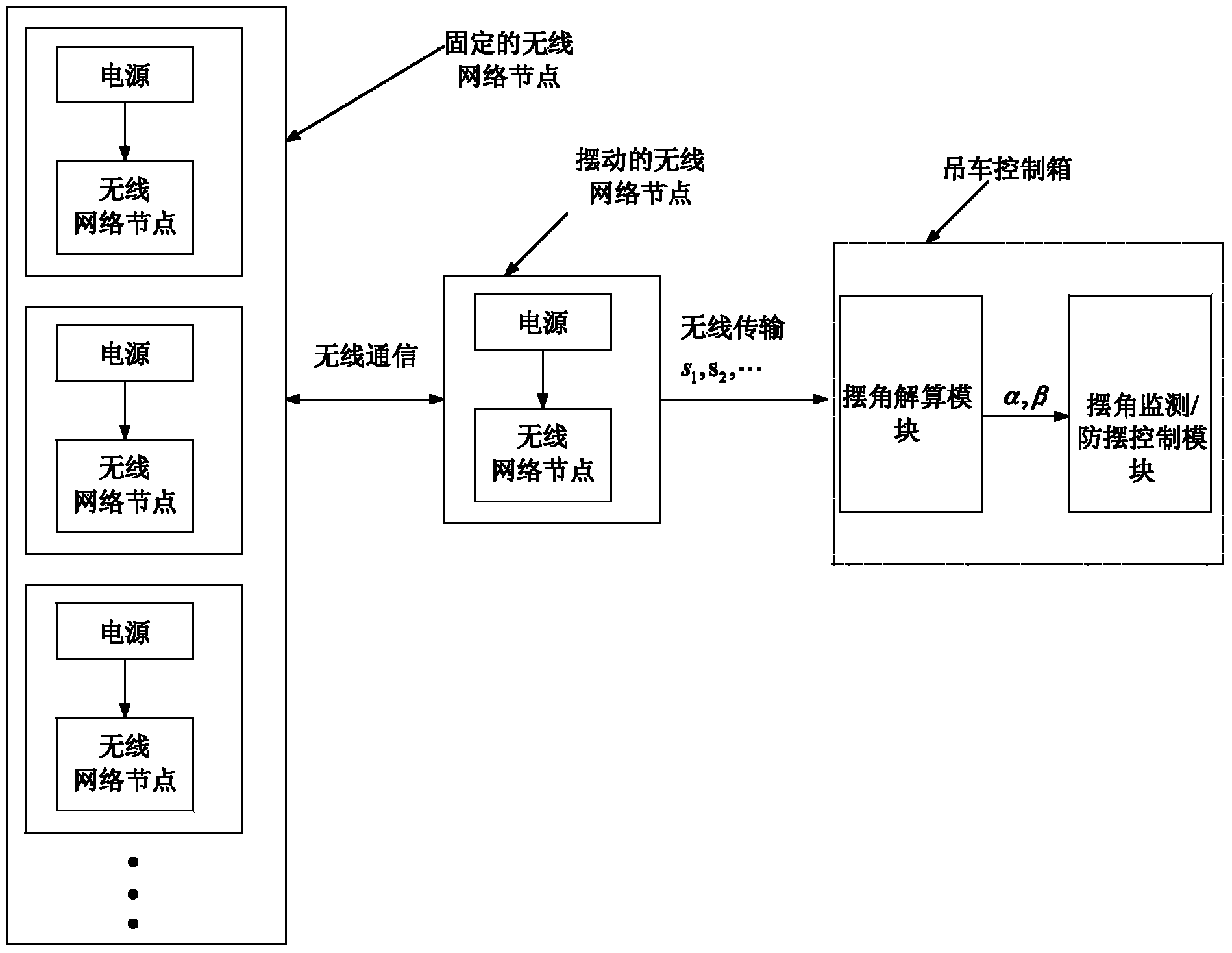

[0021] A crane load swing angle detection method. The hook / load is connected to the mobile trolley on the crane body through a sling. Two or more wireless network fixed nodes are installed on the crane body, and a wireless network is installed on the hook / load. Network swing node: The swing node communicates with all fixed nodes respectively, and realizes the spatial position positioning of the hook / load based on the received signal strength index RSSI ranging technology, and finally calculates the spatial swing angle of the load.

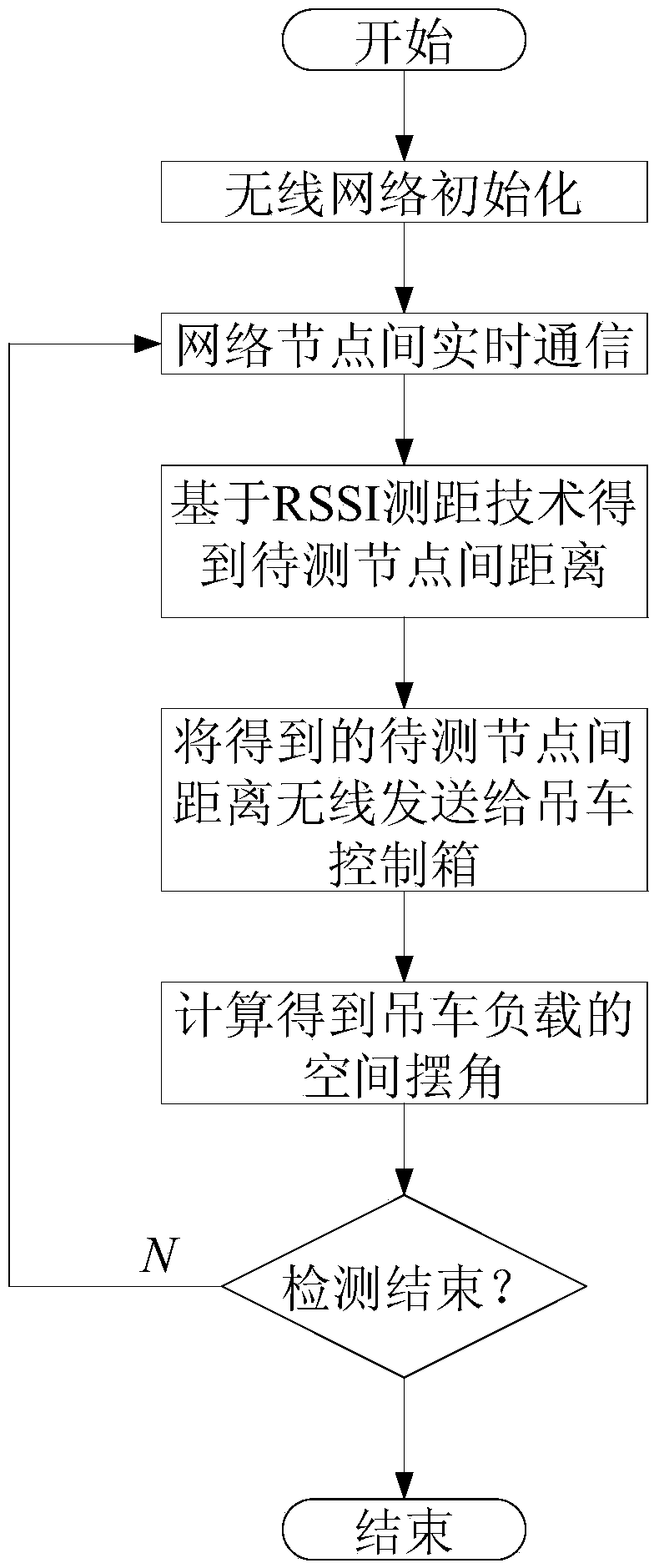

[0022] Such as figure 1 As shown, the above method specifically includes the following steps:

[0023] (1) The fixed node / swing node continuously sends out network signals steadily;

[0024] (2) The swing node / fixed node receives and processes the network signal from the fixed node / swing node in real time, and uses RSSI ranging technology to obtain the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com