Sectional steel flat support device Rotary arm drive chain tensioner

A technology of tensioning device and rotating arm, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to lock the chain, poor compactness and stability, and achieve simple and compact structure and long service life. Long, adjustable fast and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

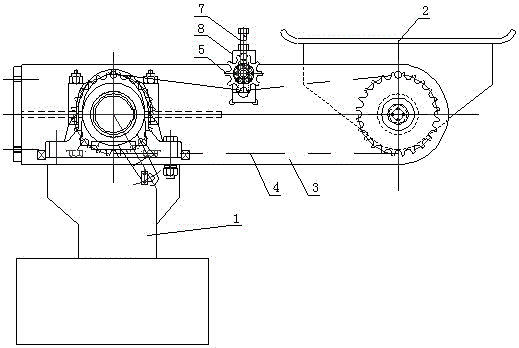

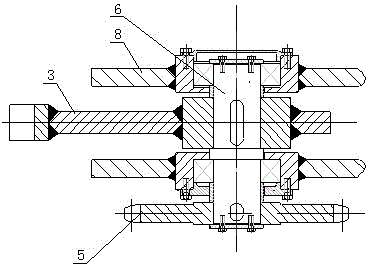

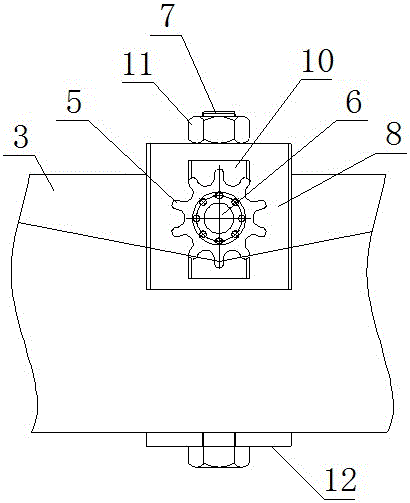

[0020] Such as Figure 3-Figure 4 As shown, a tensioning device for the transmission chain of the rotary arm of the steel flat support device includes a tensioning wheel 5, a fixed shaft of the tensioning wheel 6 and an adjustment rod 7, and the fixed shaft of the tensioning wheel 6 is perpendicular to the direction of the partition of the rotating arm and is horizontal Set and one end extends out of the side of the partition 3 and fixes the tension wheel 5; wherein the other end of the tension wheel fixed shaft 6 extends vertically out of another partition and is screwed with a lock nut 9, the The two partitions where the tension wheel fixed shaft 6 is located are correspondingly provided with a bar hole 10 for adjusting the vertical displacement of the tension wheel fixed shaft (the width of the bar hole is smaller than the diameter of the lock nut), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com